Calculation method for dust-containing airflow density of primary air tube of intermediate coal pulverizing system

A pulverizing system and airflow density technology, which is applied in the field of calculation of the dust-laden airflow density in the primary air duct of the storage type pulverizing system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The method of the present invention is used to calculate the flow rate of air powder air flow in the primary air duct of a boiler of a certain company's power station and a certain boiler:

[0059] (1) Determination of relevant parameters:

[0060] Table 1 Example 1 parameter measurement result

[0061]

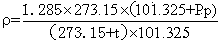

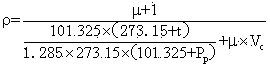

[0062] (2) Bring the parameters into the following calculation formula for calculation:

[0063]

[0064] Result: Dusty airflow density ρ=1.1382 kg / m3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com