Bearing life degradation performance evaluation index construction method based on main component analysis

A principal component analysis and evaluation index technology, applied in the field of signal processing, can solve the problems of rolling bearing life degradation, unable to fully and effectively reflect the bearing life degradation trend, difficult to obtain characteristic points of rolling bearing performance degradation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Preferred embodiments of the present invention will be described in detail below.

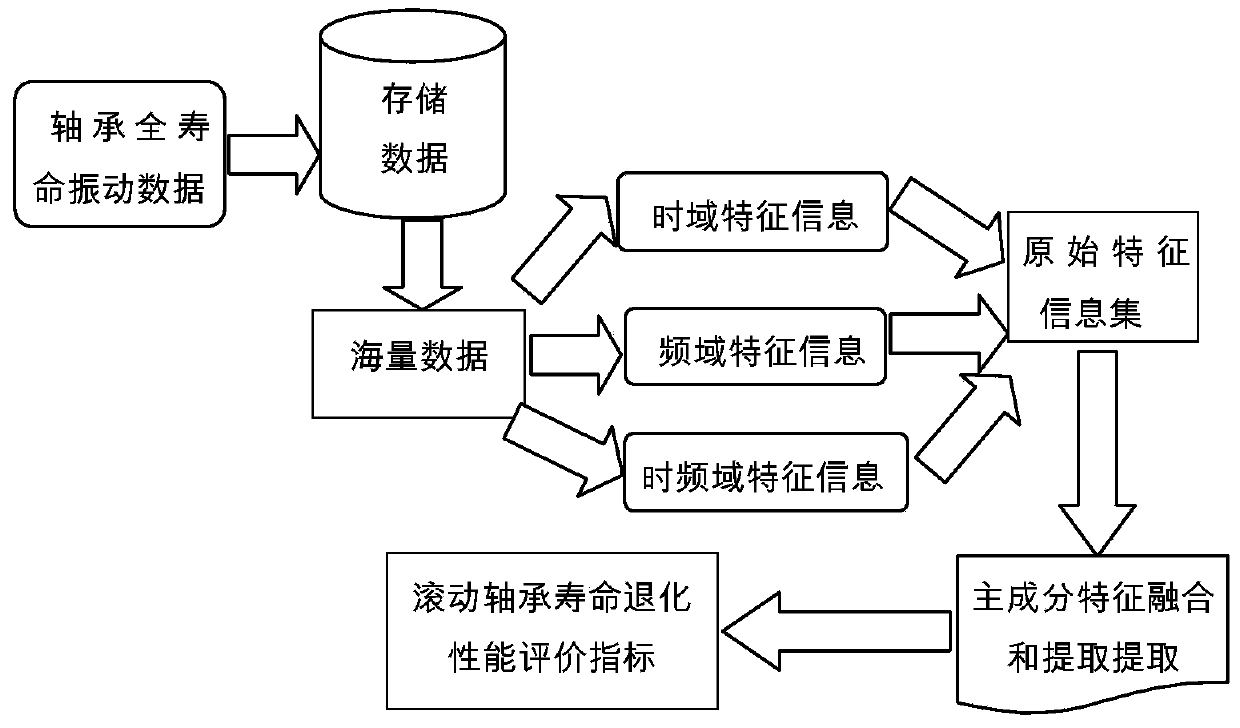

[0053] see figure 1 , this embodiment describes a method for constructing bearing life degradation performance indicators based on principal component analysis, including the following steps:

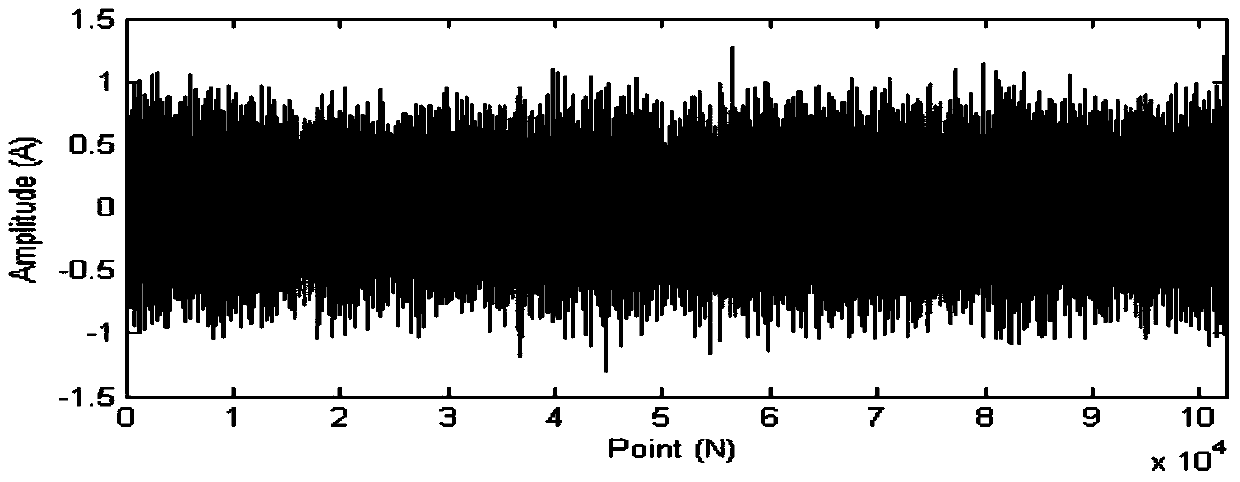

[0054] 1) Use the acceleration sensor to obtain the original vibration data of the bearing life test process. The original vibration data x(t) in this embodiment is obtained through a ground conventional bearing test. During the test, the bearing is applied with a constant load of 6000lbs, constant The rotation speed of the bearing is 2000rpm. In this process, the failure data of the bearings in different states are collected. The sampling frequency is 20kHz, and the sample length is 20480 points. The measured signal of a certain stage is as follows: figure 1 shown.

[0055] 2) Carry out time-domain signal processing to the raw vibration data of step 1) gained, obtain the time-domain indicator s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com