Hydraulic energy conversion system mounted inside tire

A technology for converting system and hydraulic energy, applied in the direction of mechanical power generating mechanism, machine/engine, mechanical equipment, etc., can solve the problems of waste and conversion, and achieve the effect of high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

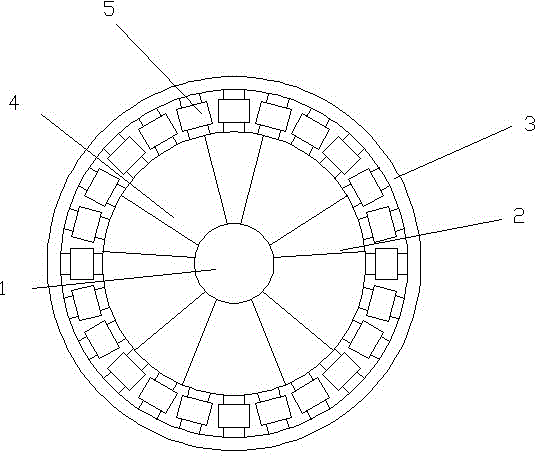

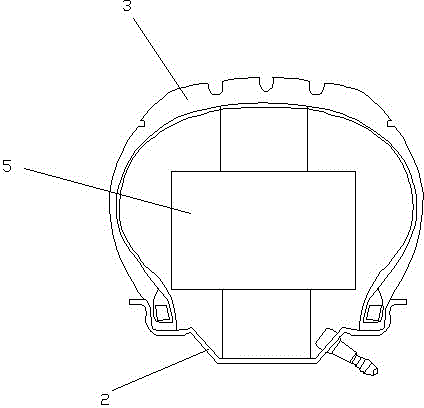

[0019] A hydraulic energy conversion system installed in the tire described in Embodiment 1, such as figure 1 , figure 2 As shown, it includes a wheel 1 used in conjunction with the main frame of the automobile. The wheel is composed of a rim 2 installed and connected to the axle, a tire 3 installed with the rim, and spokes 4 provided on the rim. A plurality of ring-shaped hydraulic systems 5 arranged on the ground; the hydraulic system is connected to the generator set on the wheel rim or the main frame of the car through the crankshaft linkage mechanism and transmits power to the generator for power generation; the hydraulic system is a hydraulic cylinder, A return spring is provided on the hydraulic cylinder for resetting the reciprocating motion of the hydraulic cylinder. This technical solution directly installs multiple hydraulic systems in the tires. The hydraulic system receives the extrusion of the ground and uses the force of the vehicle's own weight and driving fo...

Embodiment 2

[0025] This embodiment 2 is improved on the basis of embodiment 1, and the specific difference of this embodiment 2 is:

[0026] The generator is directly installed and hidden in the main frame of the automobile. The generator can also be hidden in the main frame of the car and integrated with the main frame of the car to solve the installation position and complexity of the wheels.

Embodiment 3

[0028] This embodiment 3 is improved on the basis of embodiment 1, and the specific difference of this embodiment 2 is:

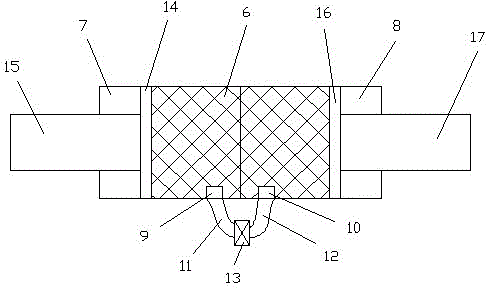

[0029] Such as Figure 5 , Image 6 As shown, the tire adopts a double-layer tire structure, specifically: the surface of the tire 3 is covered with a layer of elastic tire 33 to form a double-layer tire, and the hydraulic system 5 is located between the tire surface and the back of the elastic tire.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com