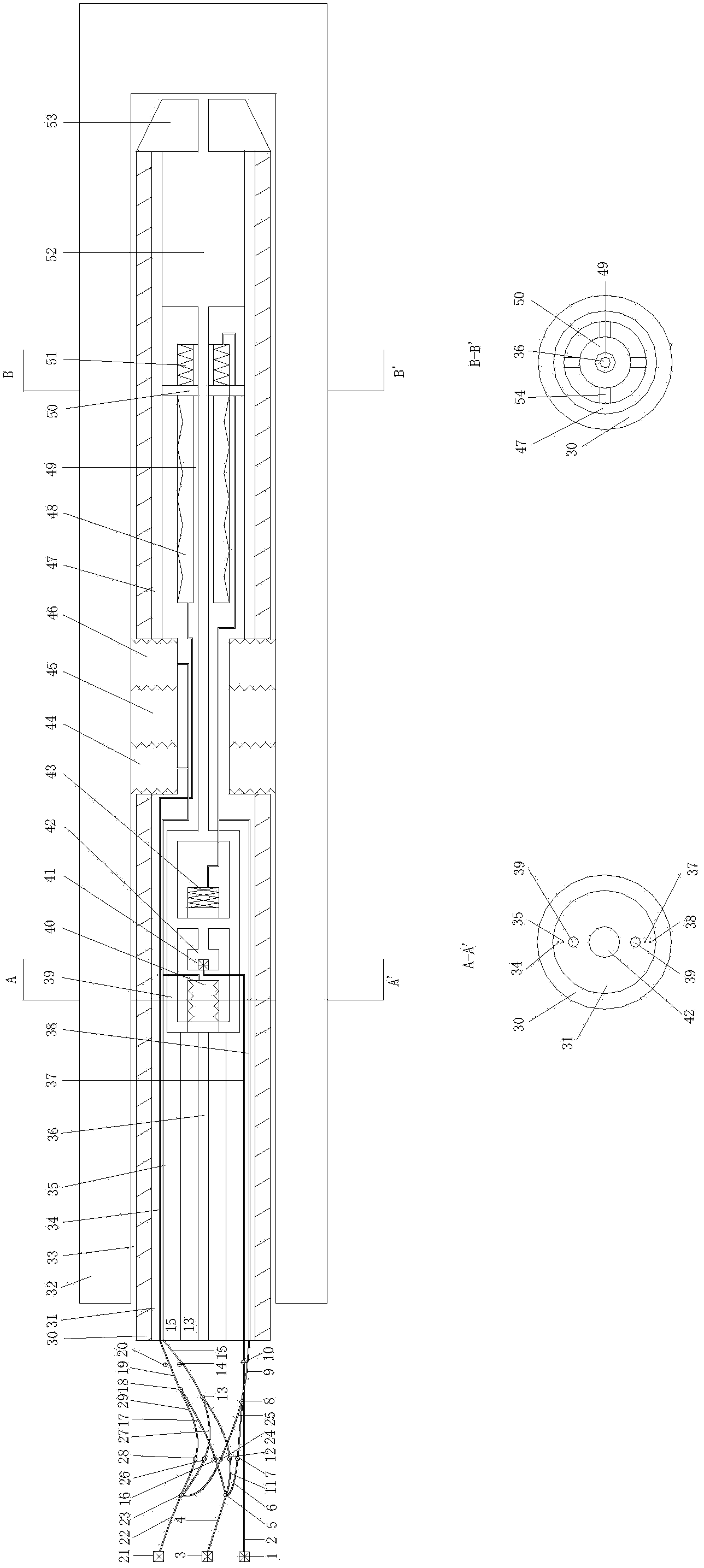

Self-drilling type in-situ measuring device of coal seam gas pressure

A coal seam gas pressure and measuring device technology, applied in the direction of measurement, drill pipe, drill pipe, etc., can solve the problems that the pressure measurement cannot be carried out, prolong the gas release time, shorten the test time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0014] The invention provides a self-drilling type coal seam gas pressure in-situ measuring device.

[0015] Such as figure 1 Shown, the specific steps of the present invention are as follows.

[0016] (1) After drilling to the set depth, move the drill pipe to the direction of the drilling hole. The moving distance is greater than the width of the sealing capsule groove and less than twice the width of the sealing capsule groove. The drilling rig retreats a certain distance, and the drilling rod is withdrawn from the drilling rig.

[0017] (2) Connect the high-pressure aluminum-plastic pipe (7) 19 and the liquid supply channel (1) 34, the high-pressure aluminum-plastic pipe (5) 15 and the liquid supply channel (2) 35, the high-pressure aluminum-plastic pipe (3) 9 and the liquid supply channel (3) 38, the gas pressure measuring wire 2 and the wires i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com