Blowout prevention device and method for well repair of pumping well

A technology for blowout prevention devices and pumping wells, which is applied in wellbore/well components, earthwork drilling, sealing/isolation, etc. It can solve problems such as low success rate, oil layer pollution, and non-reusable use, so as to improve the success rate , increase sealing, increase the effect of sand control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

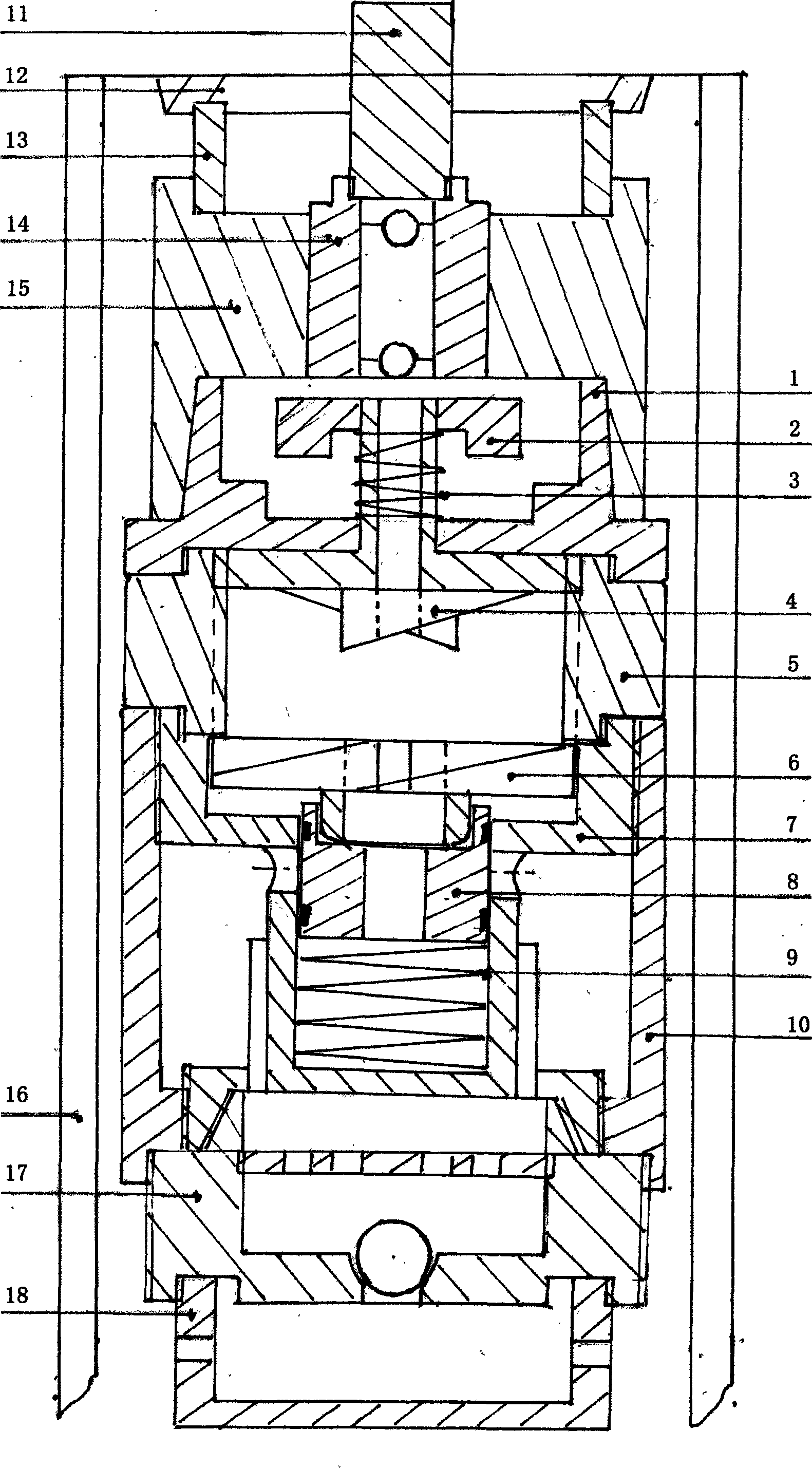

[0008] The invention will be further described below in conjunction with the accompanying drawings, as shown in the figure: the invention includes an upper joint 1, a compression head 2, an upper spring 3, a moving pressure claw 4, a track cylinder 5, a rotating pawl 6, an inner cylinder 7, and a sliding sleeve 8. The lower spring 9 and the outer cylinder 10 constitute a complete technical solution. The specific implementation process is: firstly, the screen pipe 18 is connected to the lower part of the fixed valve 17, the blowout prevention device is adjusted to the closed state, and the lower part of the inner cylinder 7 The internal thread is connected with the external thread on the fixed valve 17, the internal thread on the lower part of the oil pump barrel 15 is connected with the external thread on the joint 1 of the blowout preventer, and the screen pipe 18 is inserted from the bottom up and down, and the valve 17 is fixed. The blowout prevention device, the oil pump ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com