Parallel torque coupling type energy-saving workover rig

A torque coupler, coupled technology, applied in drilling equipment, earthwork drilling, drill pipe, etc., can solve problems such as energy waste, reduce costs, reduce energy conversion links, and improve efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

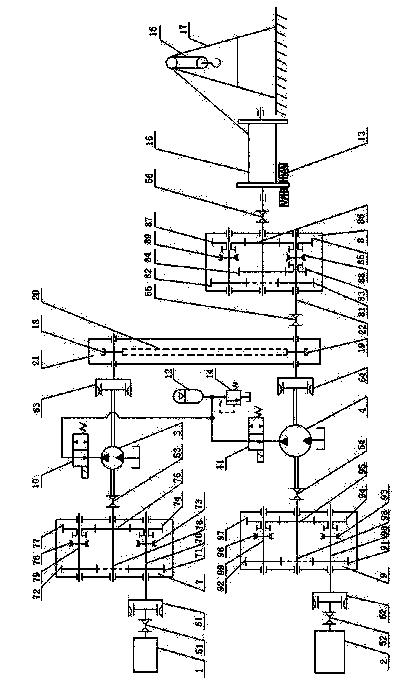

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings. Referring to the accompanying drawings, the parallel torque coupled energy-saving workover rig includes a small power machine 1, a large power machine 2, a gearbox 8, a drum 15, a traveling block hook 16, a drum brake 13, and a derrick 17. It also includes a first torque Coupler 7, second torque coupler 9, third torque coupler 21, small quantitative hydraulic pump / motor 3, large quantitative hydraulic pump / motor 4, first reversing valve 10, second reversing valve 11, Hydraulic accumulator 12, overflow valve 14. The displacement of the small quantitative hydraulic pump / motor 3 is smaller than the displacement of the large quantitative hydraulic pump / motor 4 . The first shaft 70, the second shaft 78 and the third shaft 79 are installed in the first torque coupling 7; the first gear 71 is fixedly installed on the first shaft 70, the first meshing sleeve 73 is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com