Flat-plate gas-lift circulation type algae culture photosynthetic reactor and microalgae culture method using flat-plate gas-lift circulation type algae culture photosynthetic reactor

A technology for photosynthetic reactors and airlift circulation, applied in photobioreactors, methods based on microorganisms, bioreactor/fermenter combinations, etc., can solve the problem of not considering the influence of reactor flow field and light intensity To achieve the effect of promoting the flash effect, increasing the photosynthesis and biomass production of microalgae, strengthening gas-liquid stirring and material transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

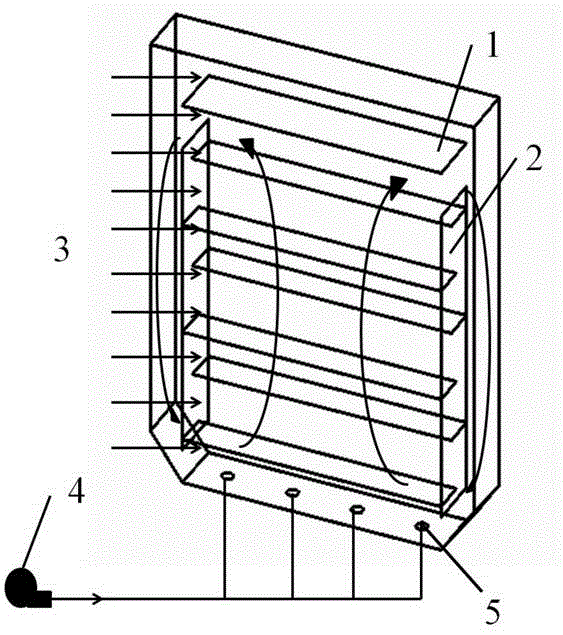

[0036] The material of the flat air-lift circulation algae-growing photosynthetic reactor is toughened glass with a thickness of 7.0 mm, which was purchased from Hangzhou Jingding Glass Products Co., Ltd. The height of the flat air-lift circulation type algae-growing photosynthetic reactor is 600cm, the width is 400cm, and the thickness is 20cm. Two vertical partitions 2 on the left and right divide the whole flat-plate air-lift circulation type algae-culture photosynthetic reactor into a central flow rising area and two A two-sided flow drop zone. In the central flow ascending area of the flat air-lift circulation type algae-growing photosynthetic reactor, cross-draining transverse partition groups are equidistantly arranged, and the upper and lower intervals of each transverse partition 1 are 20 cm, and the transverse width of the transverse partition 1 15cm, the transverse partitions 1 are respectively fixed on the front wall 6 and the rear wall 7 to intersect, and the ch...

Embodiment 2

[0039] The material of the flat air-lift circulation algae-growing photosynthetic reactor is polystyrene (PS) with a thickness of 4.0 mm, which was purchased from Hangzhou Jingding Glass Products Co., Ltd. The height of the flat air-lift circulation algae-growing photosynthetic reactor is 300cm, the width is 200cm, and the thickness is 10cm. The left and right vertical partitions 2 divide the entire flat-plate air-lift circulation algae-growing photosynthetic reactor into a central flow rising area and two Downflow zone on both sides. In the central flow ascending area of the flat air-lift circulation type algae-growing photosynthetic reactor, the cross-drainage transverse partition group is equidistantly arranged, and the upper and lower distances of each transverse partition 1 are 8.0cm, and the transverse width of the transverse partition 1 Both are 6cm, and the transverse partitions 1 are respectively fixed on the front wall 6 and the rear wall 7 to cross and arrange, an...

Embodiment 3

[0042] The material of the flat air-lift circulation algae-growing photosynthetic reactor is plexiglass with a thickness of 5.0 mm, which was purchased from Hangzhou Jingding Glass Products Co., Ltd. The height of the flat air-lift circulation type algae-growing photosynthetic reactor is 40cm, the width is 30cm, and the thickness is 5cm. Two vertical partitions 2 on the left and right divide the whole flat-plate air-lift circulation type algae-culture photosynthetic reactor into a central flow rising area and two A two-sided flow drop zone. In the central flow ascending area of the flat air-lift circulation type algae-growing photosynthetic reactor, cross-draining transverse partition groups are equidistantly arranged. Both are 3.0 cm, and the transverse partitions 1 are respectively fixed on the front wall 6 and the rear wall 7 to cross and arrange, and the channel width for the upward flow of the algae liquid is reserved to be 2.0 cm. Four glass sand cores 5 with a diamet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com