Alkaline residue flower ceramsite and manufacturing method thereof

A flower ceramsite and alkali residue technology, applied in the field of environmental protection technology, can solve the problems of low ceramsite strength, high price, consumption of cultivated land resources, etc., and achieve the effects of purifying the surrounding environment, high water absorption, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

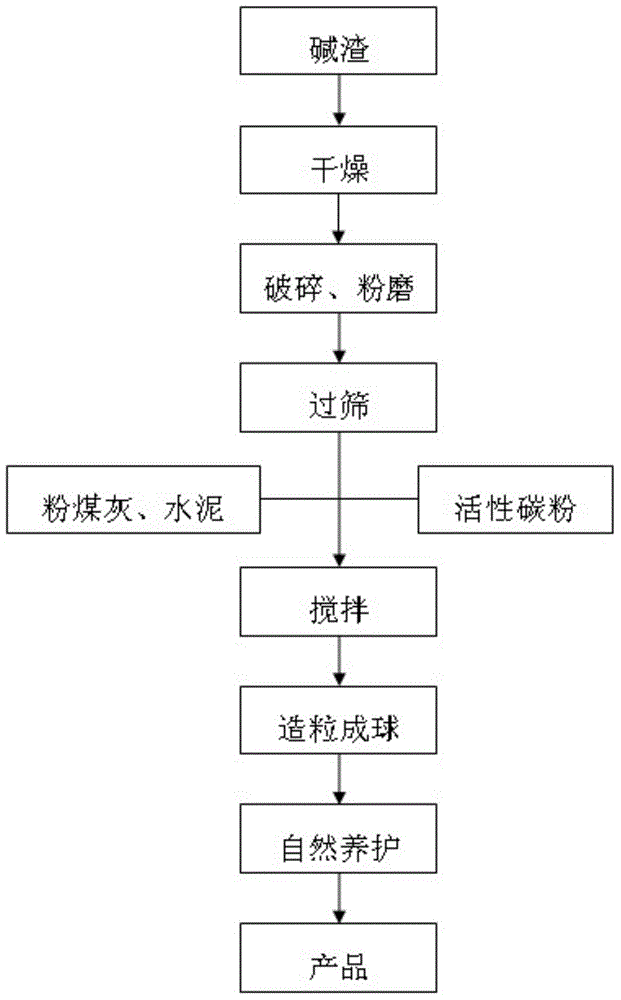

Method used

Image

Examples

example 1

[0022] Example 1: Alkali slag consumption 40wt%, fly ash 20%, cement 40wt%, externally mixed with 0.5% active carbon powder;

[0023] Single particle strength (7 days): 1.6MPa; Bulk density: 743kg / m 3 .

example 2

[0024] Example 2: Alkali slag consumption 45wt%, fly ash 20%, cement 35wt%, externally mixed with 0.5% active carbon powder;

[0025] Single particle strength (7 days): 1.6MPa; Bulk density: 756kg / m 3 .

example 3

[0026] Example 3: Alkali slag consumption 50wt%, fly ash 20%, cement 30wt%, externally mixed with 0.5% active carbon powder;

[0027] Single particle strength (7 days): 1.3MPa; Bulk density: 790kg / m 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com