Cleaning and oil flushing device and method for unit lubricating oil system pipeline

A lubricating oil and oil flushing technology, applied in cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., can solve the problems of long cleaning and purification time, incomplete cleaning, and polluting machines, so as to achieve pollution-free and practical construction Strong performance and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

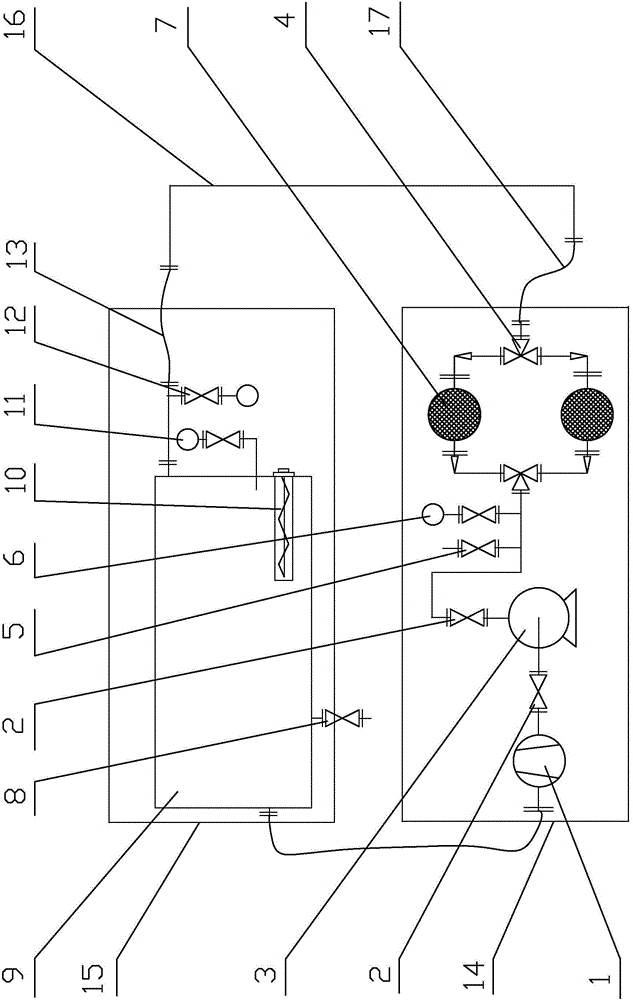

[0039]The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0040] The unit lubricating oil system pipeline cleaning and oil flushing device of the present invention includes a pump supply unit 14 and a return flow unit 15 . A coarse filter 1 (filtering precision selected as 400 μm to 500 μm), a stainless steel centrifugal pump 3 (working pressure 0.3MPa to 0.8MPa, flow rate 40m 3 / h~80m 3 / h) and a duplex filter 7 (the filtration accuracy is selected as 5 μm to 120 μm), between the coarse filter 1 and the centrifugal pump 3, and between the centrifugal pump 3 and the duplex filter 7 through pipes The inlet and outlet pipelines of the centrifugal pump 3 are each equipped with a shut-off valve 2, and the outlet pipeline of the centrifugal pump 3 (behind the shut-off valve 2) is also provided with a pressure gauge 6 and a nitrogen interface 5. The duplex filter 7 is alternately...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com