Transfer film for in-mold injection showing three-dimensional pattern, and preparation method thereof

A technology of in-mold injection molding and transfer printing film, which is applied to the device for coating liquid on the surface, chemical instruments and methods, printing of special varieties of printed matter, etc. It can solve the problems that the optical gradient of the three-dimensional pattern cannot be displayed, and achieve a strengthened surface. The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

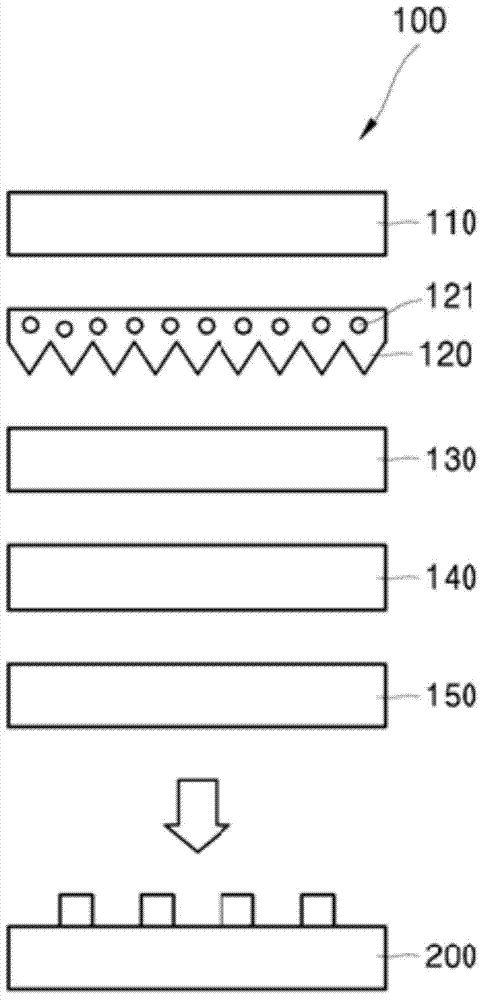

[0035] Preparation method of transfer film for in-mold injection molding

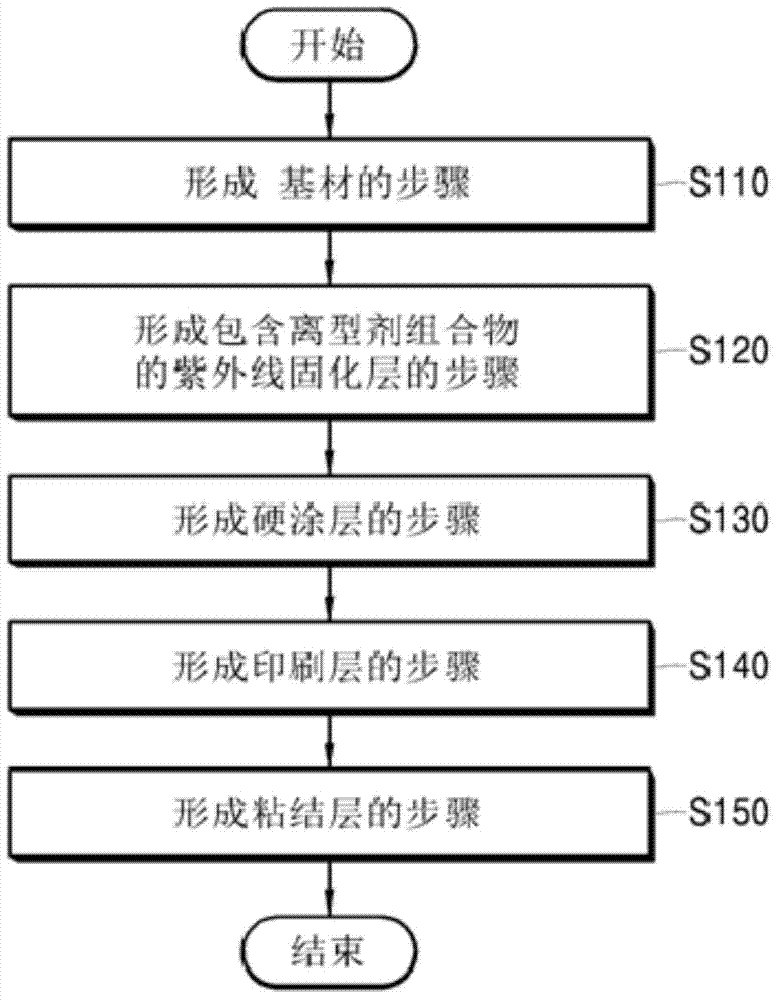

[0036] figure 2 It is a flow chart showing the manufacturing process of the transfer film for in-mold injection molding of the Example of this invention.

[0037] refer to figure 2 , the preparation process of the transfer film for in-mold injection molding of the present invention comprises: the step S110 of forming the substrate, the step S120 of forming an ultraviolet curable layer comprising a release agent composition on the upper part of the substrate, and the step S120 of forming the ultraviolet curable layer on the above substrate Step S130 of forming a hard coat layer on top, step S140 of forming a printing layer on top of the hard coat layer, and step S150 of forming an adhesive layer on top of the printing layer.

[0038] The step S120 of forming a UV-curable layer comprising a release agent composition on the upper part of the base material includes the step of forming a three-dimensio...

Embodiment

[0050] A UV curable layer is formed on the upper part of a 50 μm thick polyethylene terephthalate film, and then a 5 μm thick three-dimensional pattern is formed on the upper part of the UV curable layer using a micro gravure coating method, wherein the above UV curable layer contains 50 % by weight of urethane acrylate, 5% by weight of photoinitiator (benzoin methyl ether), 35% by weight of additives (sodium lauryl sulfate) and 10% by weight of silicone acrylate oligomers, In addition, the thickness of the ultraviolet curing layer was 20 μm. Thereafter, it was cured with a metal halide ultraviolet lamp (lamp power: 400 mJ, curing speed: 5 m / min).

[0051] Afterwards, a hard coat layer is formed, and a modified acrylic polyol-based vapor deposition primer composition is coated with a thickness of 1 μm on the top of the hard coat layer, and then cured at a temperature of 120° C. for 20 seconds to form a vapor deposition primer. paint layer.

[0052] Afterwards, a printed laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com