Nonlinear ultrasonic heat treatment process evaluation and optimization method and device

A nonlinear ultrasonic and nonlinear acoustic technology, which is used in the analysis of solids, materials, and instruments using sonic/ultrasonic/infrasonic waves. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

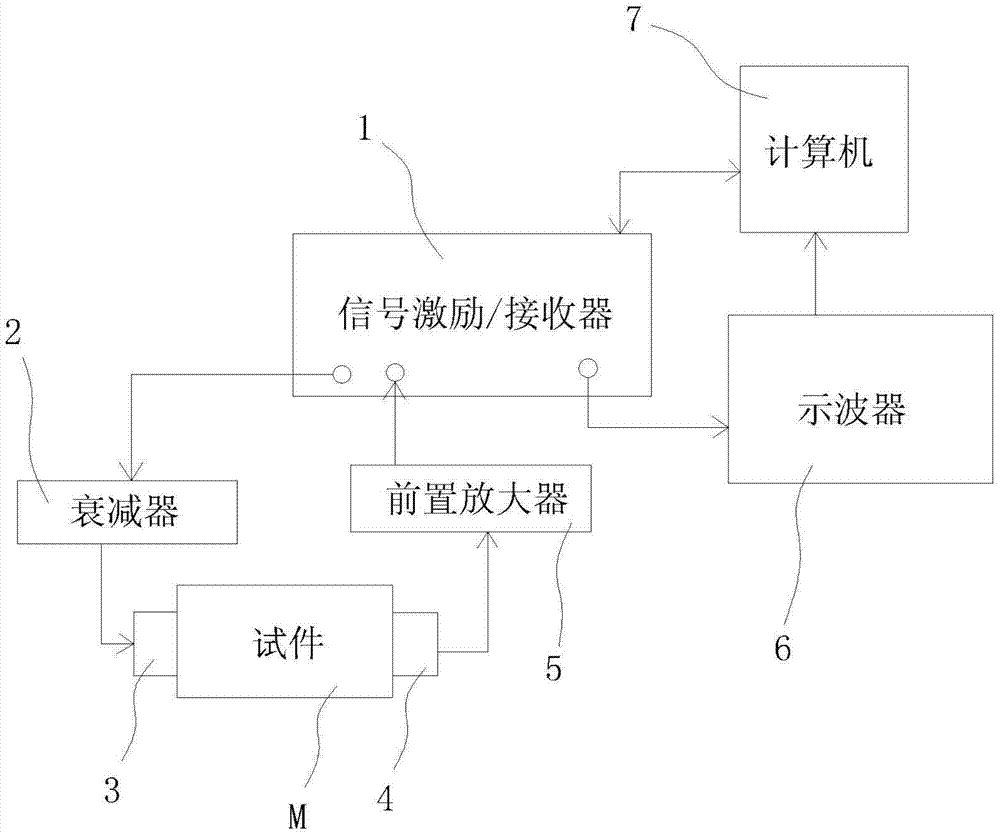

[0030] Example: see figure 1 and figure 2 , a device for nonlinear ultrasonic evaluation and optimization of heat treatment process, including signal excitation / receiver 1, attenuator 2, excitation probe 3, receiving probe 4, preamplifier 5, oscilloscope 6 and computer 7, signal excitation / receiver 1 Excite a certain frequency ultrasonic signal suitable for the test piece, pass through the attenuator 2 to improve the signal-to-noise ratio and connect the excitation probe 3, the ultrasonic signal is introduced into the test piece M, and the receiving probe 4 is connected to the other end of the test piece M to detect the propagating sound wave The signal is filtered by the preamplifier 5 and sent to the oscilloscope 6. The oscilloscope acquires the received signal waveform and inputs it into the computer 7; the data obtained by the signal excitation / receiver is also input into the computer 7 for signal analysis.

[0031] A method for nonlinear ultrasonic evaluation and optimi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com