Fiber bragg grating low-frequency strain sensing demodulation system

A fiber grating and demodulation system technology, applied in the field of optical fiber, can solve the problems of small dynamic range of strain measurement, limited strain measurement accuracy, poor linearity of tunable laser scanning, etc., to reduce cost, improve precision and dynamic Range, the effect of solving the limited accuracy of strain measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

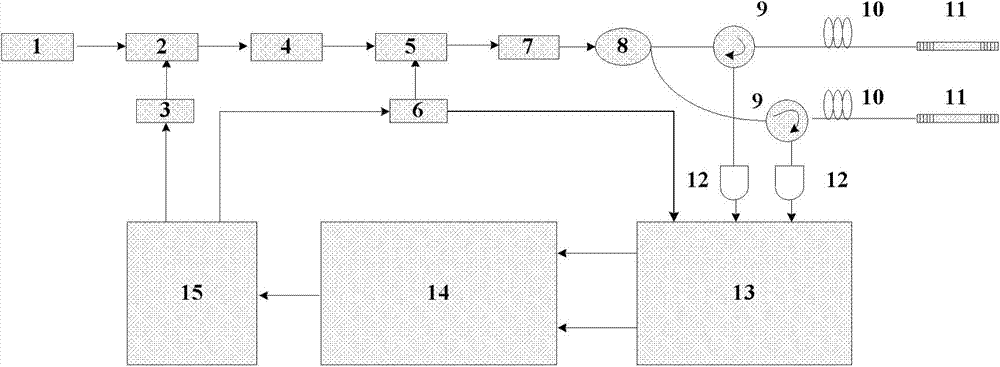

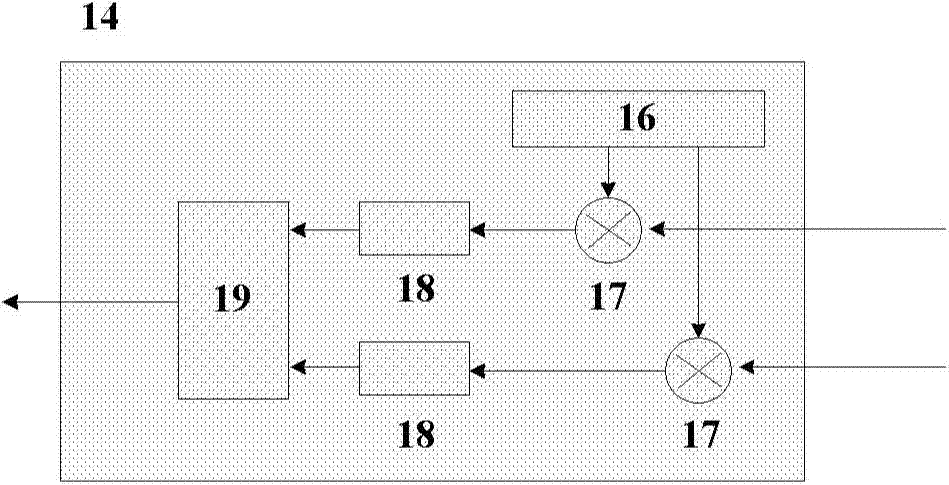

[0028] Please refer to figure 1 ,in figure 1 A structural schematic diagram of a high-precision fiber grating low-frequency strain sensing demodulation system based on laser linear sweep modulation technology and PDH frequency-locked sensing technology provided by the present invention.

[0029] Such as figure 1 As shown, the high-precision fiber grating low-frequency strain sensing demodulation system includes:

[0030] A narrow linewidth laser 1 is used to provide a narrow linewidth laser light source for the entire demodulation system;

[0031] The electro-optic / acousto-optic modulator 2 is used to modulate the laser output from the narrow-linewidth laser 1 according to the linear frequency modulation signal generat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com