Dynamic two-dimensional photoelectric microscope

A photoelectric microscope and dynamic technology, applied in the field of microscopy, can solve the problems that restrict the development of two-dimensional line measurement and calibration technology, cannot meet the two-dimensional line measurement and calibration, and limit the resolution of optical microscopes, so as to solve the problem of synchronous dynamic measurement Distinguishing from measurement space, avoiding low measurement efficiency, good adaptability and measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The dynamic two-dimensional photoelectric microscope of the present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

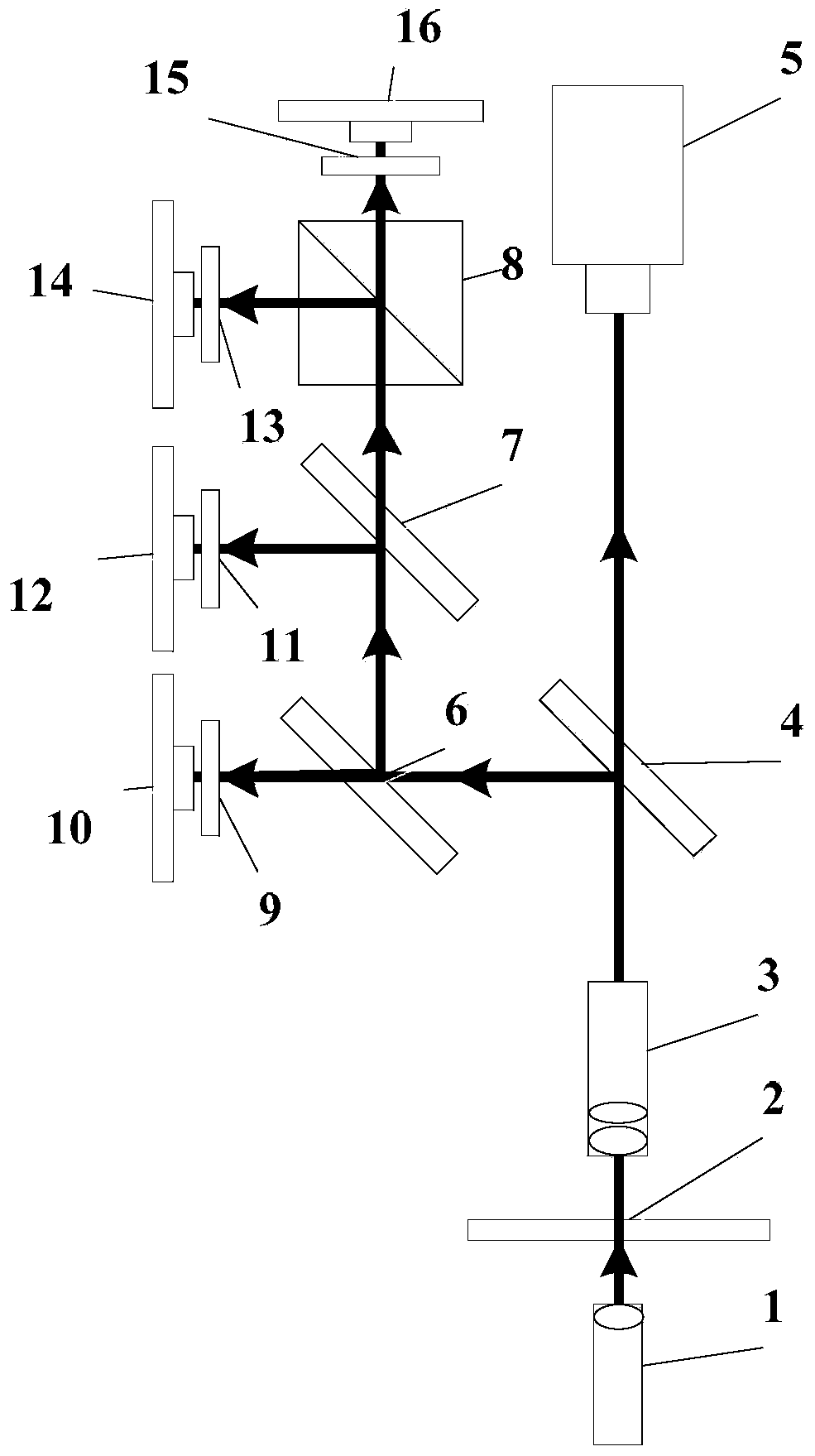

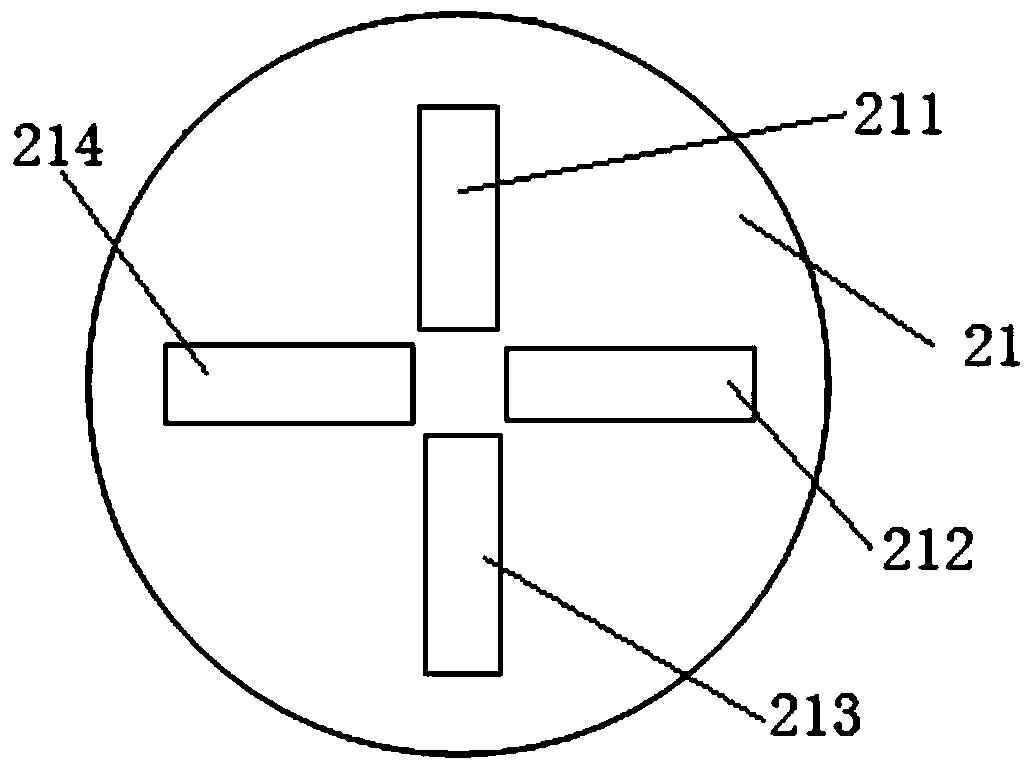

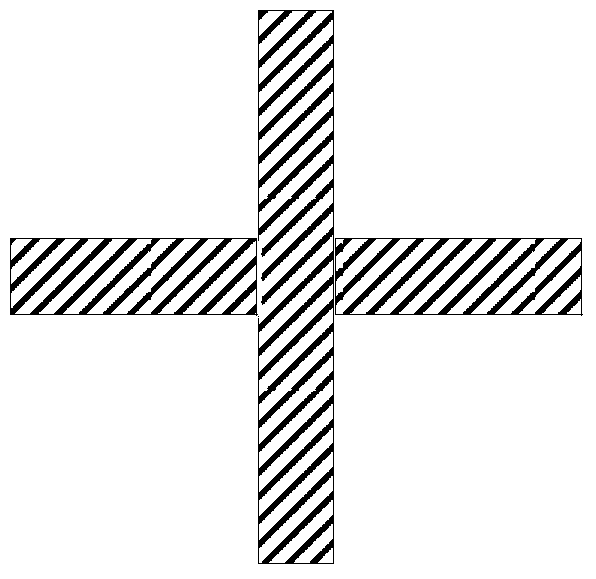

[0034] Such as figure 1 As shown, the dynamic two-dimensional photoelectric microscope of the present invention includes an illumination light source 1 for illuminating the measured two-dimensional line pattern template 2, and an photoelectric microscope objective lens 3 for introducing the real image of the measured two-dimensional line pattern template 2 into the measurement system, It is arranged on the output optical path of the objective lens 3 of the photoelectric microscope, and is used to divide the light of this path into two paths of light for observation and measurement. An imaging CCD camera 5 on the optical path for observation, the imaging CCD camera 5 receives the light for observing and adjusting the measured two-dimensional line pattern template 2 during measurement, and is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com