Planetary gear speed reducer capable of carrying out torque detection simultaneously

A gear reducer and torque detection technology, which is applied in the field of speed or torque devices and speed adjustment devices, can solve the problems of low signal measurement accuracy, inconvenient use, and low accuracy, and achieve a simple and reliable torque measurement principle , Simplified power transmission system, simple and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

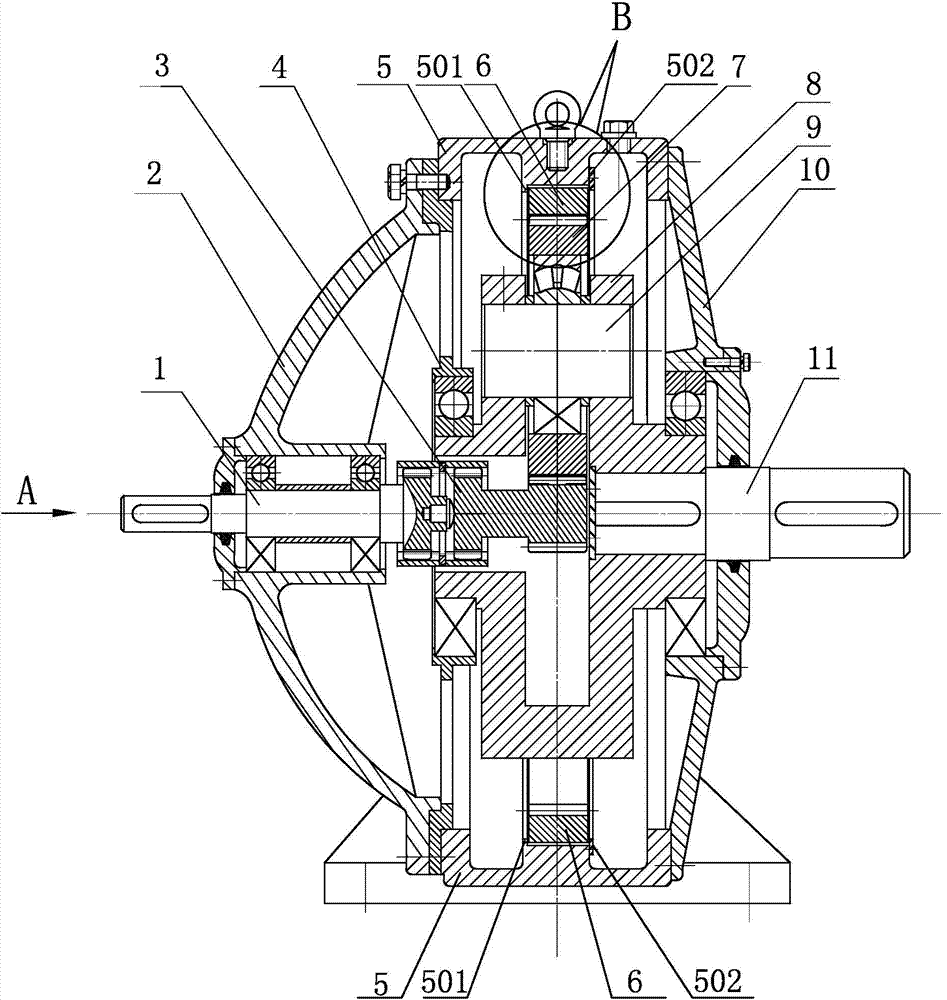

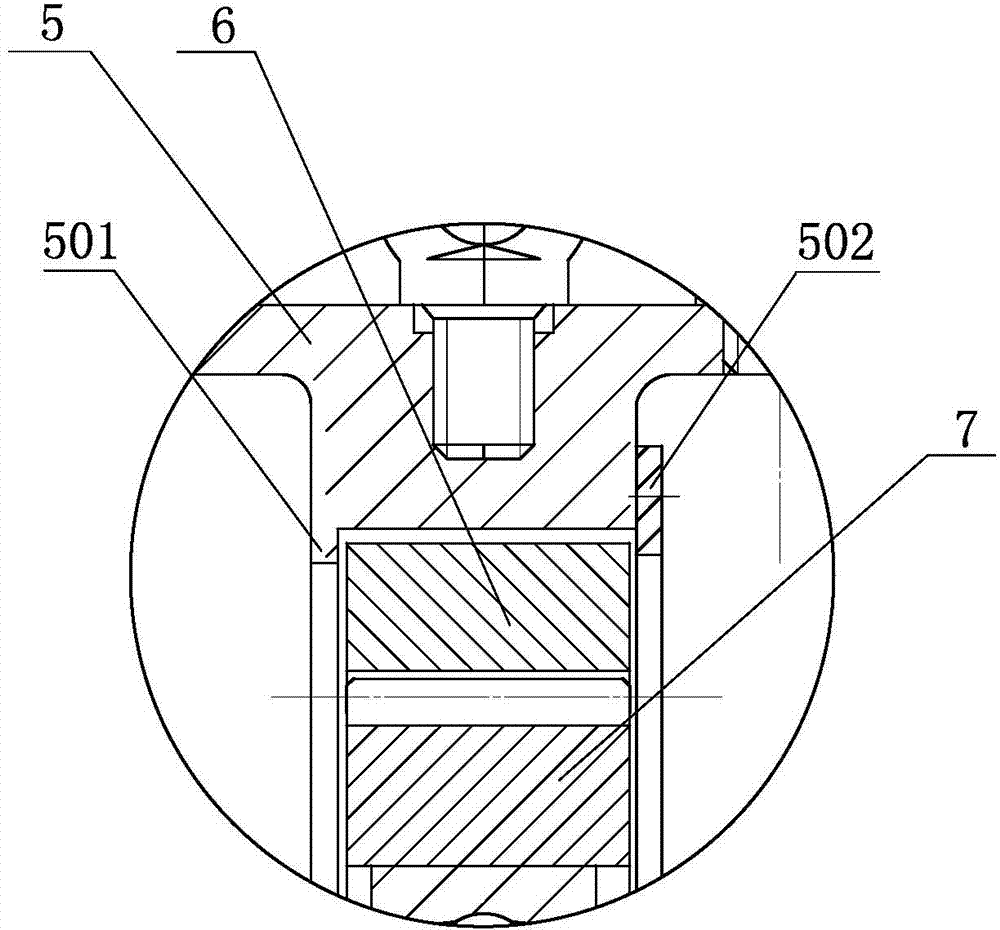

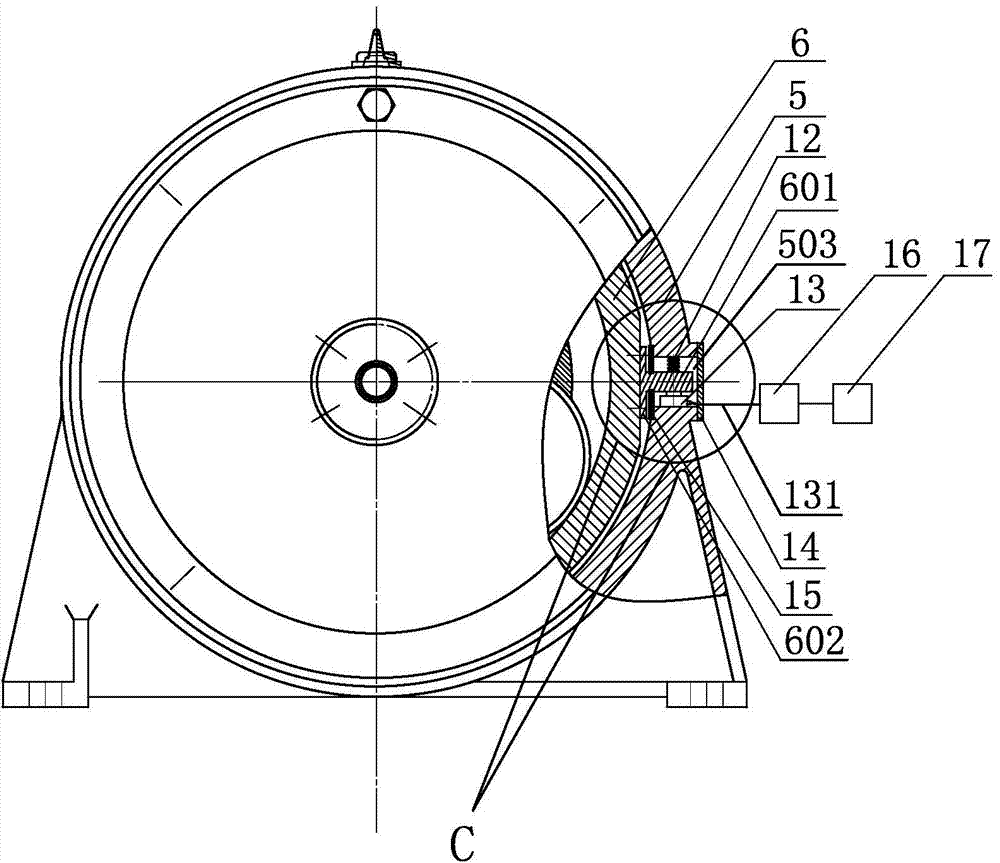

[0026] Such as figure 1 , figure 2 As shown, the planetary gear reducer capable of simultaneous torque detection in the present invention includes an input shaft 1, a front cover 2, a sun gear 3, a bearing frame 4, a housing 5, an inner ring gear 6, a planetary gear 7, a planet carrier 8, Main parts such as the planetary gear shaft 9, the rear cover 10 and the output shaft 11, the above-mentioned parts are common parts of the planetary gear reducer, and their specific assembly methods and mutual positional relationship will not be described in detail here. Wherein, the inner ring gear 6 is embedded in the housing 5, leaving a gap between the two, the inner ring gear 6 is in a floating state, and can rotate relative to the housing 5, and the side of the inner wall of the housing 5 close to the front cover 2 is A boss 501 protruding inward is provided in the circumferential direction. On the side of the housing 5 far away from the front cover 2, a retaining ring 502 is install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com