Compound type hydraulic torque converter with overflow valve arranged externally and continuously variable transmission

An external overflow valve, hydraulic torque converter technology, applied in the direction of fluid transmission, transmission, transmission parts, etc., can solve the problems of low power, high cost, low efficiency, etc., and achieve transmission power and transmission. Efficiency improvement, high average speed, easy maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

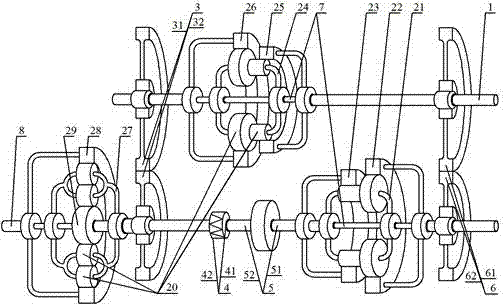

[0021] Such as figure 1 As shown in , a compound type hydraulic torque converter with external overflow valve, including input shaft 1, output gear pair 3, one-way clutch 4, external overflow valve torque converter 5, input gear pair 6 , coupling shaft 7, output shaft 8, planetary gear 20, fixed planet carrier 21, input large ring gear 22, output small ring gear 23, fixed connection planet carrier 24, The input small ring gear 25, the output large ring gear 26, the confluence planet carrier 27, the output large ring gear 28, the confluence gear 29, the input small ring gear 25 and the input gear 61 of the input gear pair 6 are connected with the input shaft 1, fixedly connected The planet carrier 24 cooperates with the input small ring gear 25 and the output large ring gear 26 through the planetary gear 20 on it, the output large ring gear 26 is connected with the input gear 31 of the output gear pair 3, and the output gear 32 of the output gear pair 3 is connected with the T...

Embodiment 2

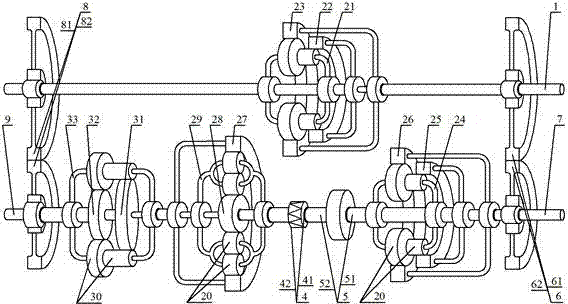

[0027] Such as figure 2As shown in , a compound CVT with an external overflow valve torque converter includes an input shaft 1, a one-way clutch 4, an external overflow valve torque converter 5, an input gear pair 6, Coupling shaft 7, confluence gear pair 8, output shaft 9, planetary gear 20, fixed planet carrier 21, output small ring gear 22, input large ring gear 23, connecting planetary gear Frame 24, connecting small ring gear 25, connecting large ring gear 26, output large ring gear 27, confluence gear 28, confluence planetary frame 29, confluence planetary gear 30, output large gear 31, confluence input pinion gear 32, confluence input The planet carrier 33, the input large ring gear 23 and the input gear 61 of the input gear pair 6 are connected with the input shaft 1, and the fixed planet carrier 21 cooperates with the output small ring gear 22 and the input large ring gear 23 through the planetary gear 20 on it, The output pinion gear 22 is connected with the input ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com