A Passive Vibration Isolation Device Suitable for Low Frequency Vibration

A low-frequency vibration and passive technology, applied in the direction of non-rotational vibration suppression, etc., can solve the problems of high cost and complex structure, and achieve the effect of small static displacement, reducing the impact of foundation vibration and impact, and small low-frequency vibration isolation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

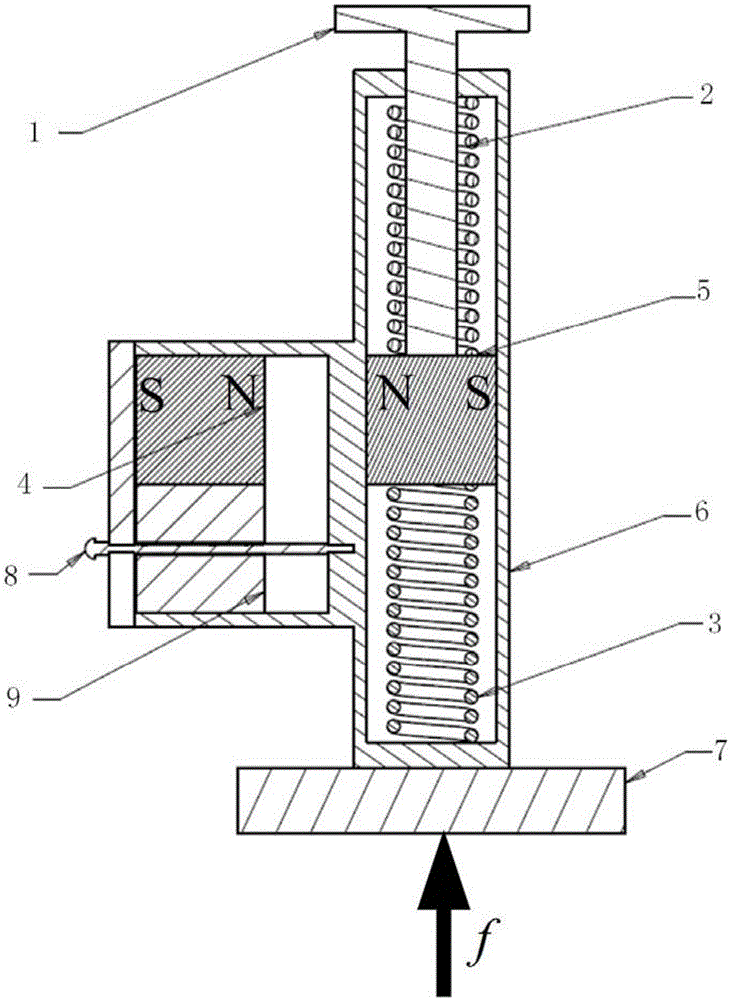

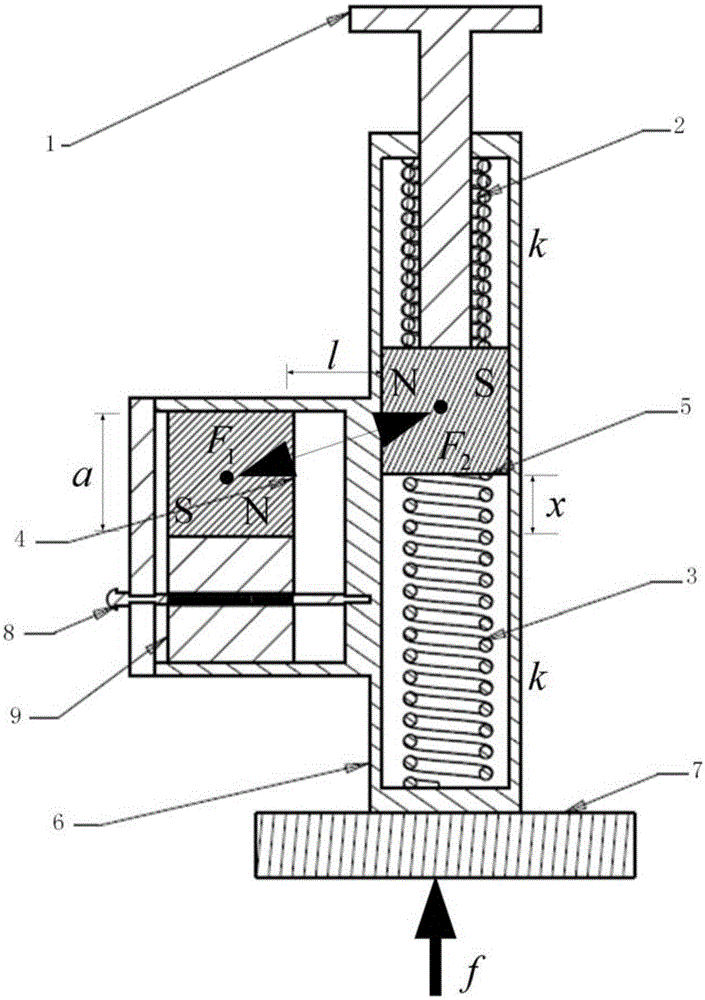

[0013] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0014] combine Figure 1~2 , the magnet 4 is fixed on the slider 9. When the magnet 4 is working, it is stationary relative to the casing in the cavity of the casing, and the distance between the magnet 5 and the magnet 5 can be adjusted through threads. The magnet 5 supported by two springs can be placed in the casing The cavity of 6 vibrates in the vertical direction, and the two magnets are facing each other when balanced. The friction between the magnet 5 and the device housing 6 produces damping, and there is a guide groove on the side of the housing cavity in the vertical direction, and the vibration isolation platform 1 and the magnet 5 are fixed in the guide groove and vibrate with the magnet 5 . The device housing 6 is made of aluminum and other hard and non-magnetic materials, and the spring is made of copper.

[0015] The device is placed vertically a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com