Multiple-working-condition hydraulic design method for guide vane type centrifugal pump

A technology of hydraulic design and centrifugal pump, applied in non-variable-capacity pumps, pumps, pump components, etc., can solve the problems of affecting the operating life of the pump, not considering partial design conditions, low efficiency, etc., to achieve high-efficiency energy-saving design, shortening Effects of the Hydraulic Design Cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

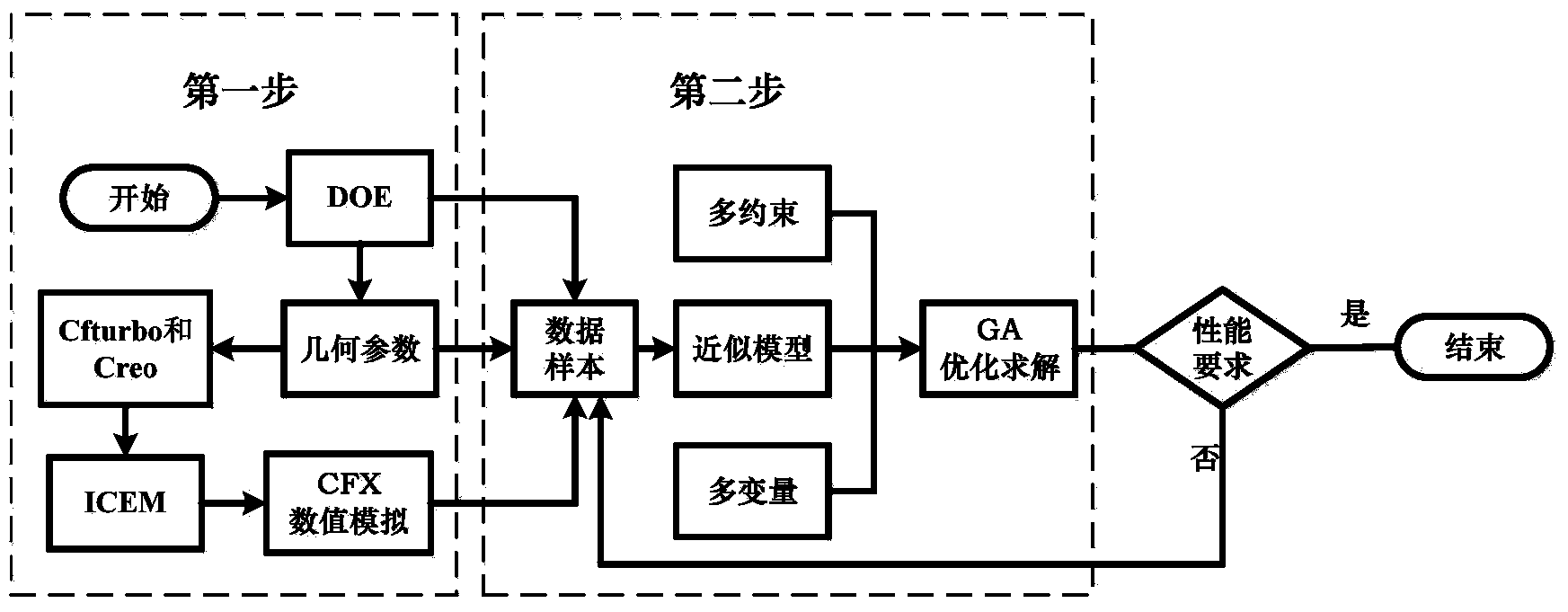

[0031] The purpose of the present invention is to provide a hydraulic design method for multi-working conditions of a guide vane centrifugal pump, through the joint test design method, CFD calculation, approximate response model and genetic algorithm for optimization, so as to obtain a set of optimal geometric parameters of the centrifugal pump , to shorten the hydraulic design cycle of the guide vane centrifugal pump in multiple working conditions.

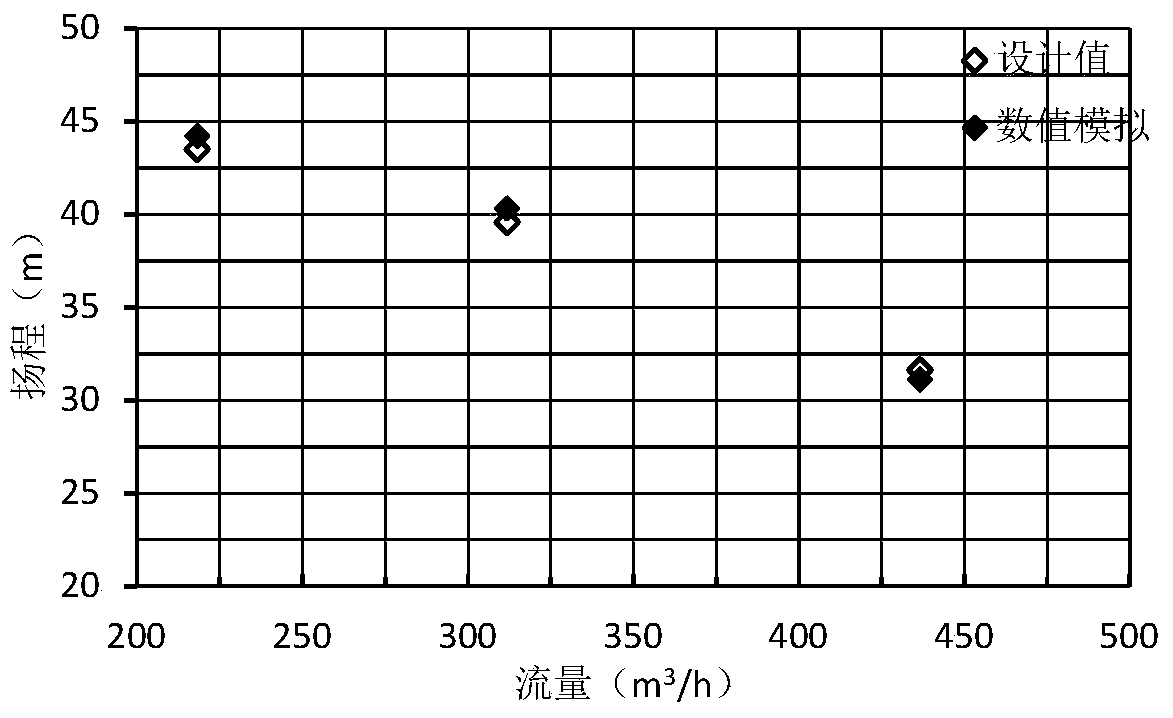

[0032] Select the design working condition of the medium specific speed as the initial design point, use the experimental design method to carry out multi-plan design for the impeller and guide vane, and select the head and the coefficient of the function fitting between the efficiency and the flow of multiple working conditions as the target , using the Kriging (Kriging model, a method for constructing the functional relationship between the target value and the design variable) model to establish an approximate response model, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com