Method for fastening mortise and tenon joint wood frame by using steel hoop

A wood frame and steel hoop technology, applied in the field of construction science, can solve problems such as impact and damage, achieve the effect of improving seismic performance and deformation capacity, and meeting installation and use requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

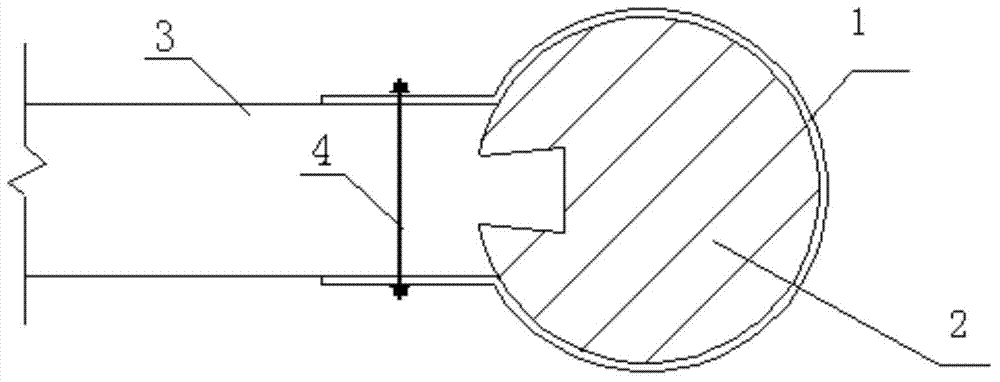

[0022] as attached figure 1 with 2 As shown, a method for reinforcing mortise and tenon joint timber frames with steel hoops is characterized in that it comprises the following steps:

[0023] The first step is to process steel hoop 1: according to the size of wooden column 2 and wooden beam 3, process steel hoop 1, that is, the height of steel hoop 1 is the same as that of wooden beam 3, steel hoop 1 covers wooden column 2, and both ends of steel hoop 1 open Extend the fixed arm to the wooden beam at 3100mm~150mm;

[0024] The second step is to install the steel hoop 1: put the steel hoop 1 on the mortise and tenon joint 201 on the wooden column 2, and fix the steel hoop 1 on the wooden beam 3 with the bolt 4.

[0025] In the first step, when the diameter of the wooden column 2 is less than or equal to 200mm, the thickness of the steel hoop 1 is 3mm-4mm; when the diameter of the wooden column 2 is greater than 200mm and less than or equal to 350mm, the thickness of the stee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com