Overall sliding construction method for large-span special-shaped space grid pipe truss

A space grid and overall sliding technology, which is applied in the direction of construction, building structure, and building material processing, can solve the problems of low construction efficiency, time-consuming and laborious, etc., and achieve the effect of uniform force and not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is further illustrated by specific examples below.

[0026] A large-span special-shaped space grid tube truss integral sliding construction method is characterized in that: it comprises the following steps;

[0027] Step 1. Determine the truss construction site according to the design drawings;

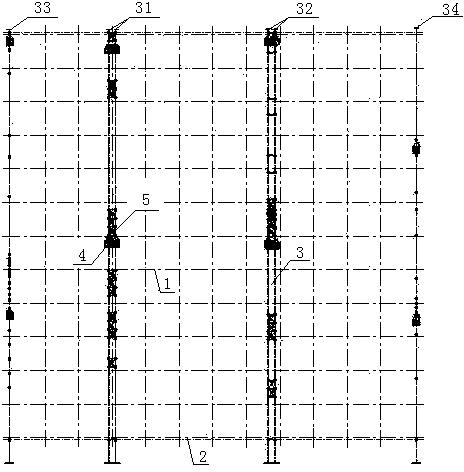

[0028] like figure 1 shown,

[0029] Step 2. Set up a trestle-type beret 1 in the building foundation pit, and lay a concrete strip foundation 2 outside the foundation pit;

[0030] Step 3. Lay four parallel tracks 3 on the trestle-type beret 1 and the concrete strip foundation 2;

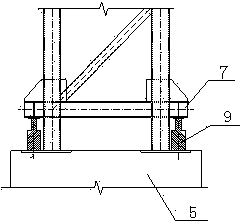

[0031] Step 4. According to the structural calculation and design height requirements, set the assembled support frame 5 and the sliding support frame 4 on the four parallel tracks 3;

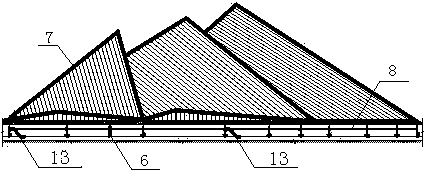

[0032] like figure 2 shown,

[0033] Step 5. Use a crane to build the truss 7 based on the sliding support frame 4 and the assembled support frame 5, wherein the assembled support frame 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com