Hanging type lifting device

A lifting equipment and suspension technology, applied in the direction of lifting frame, lifting device, etc., can solve the problems that affect the use of small manual forklifts, the manual hydraulic forklift cannot lift wooden pallets, and it is impossible to drop to the ground, etc., and achieve a simple structure. , Avoid manual unloading and ensure the effect of horizontal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

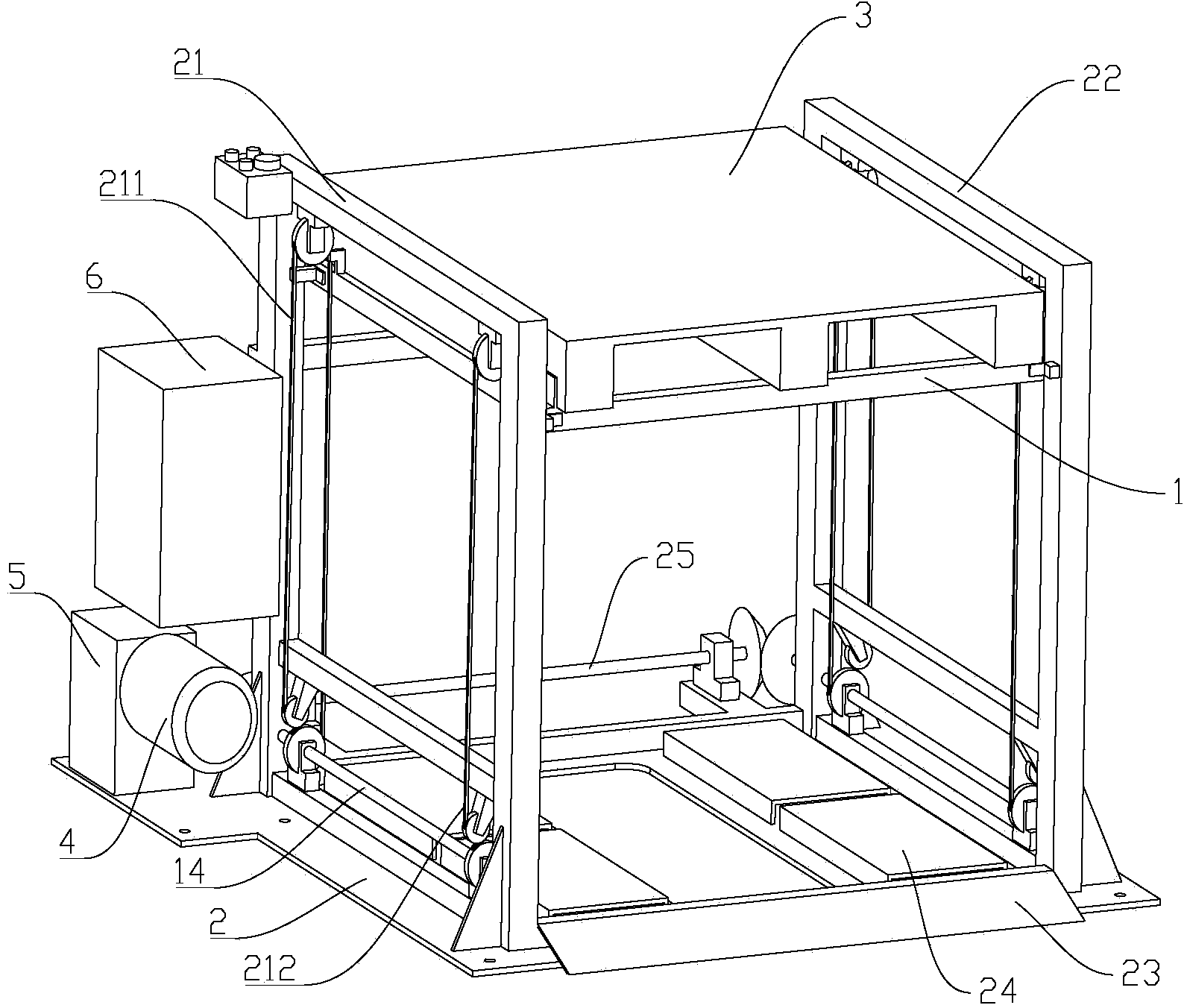

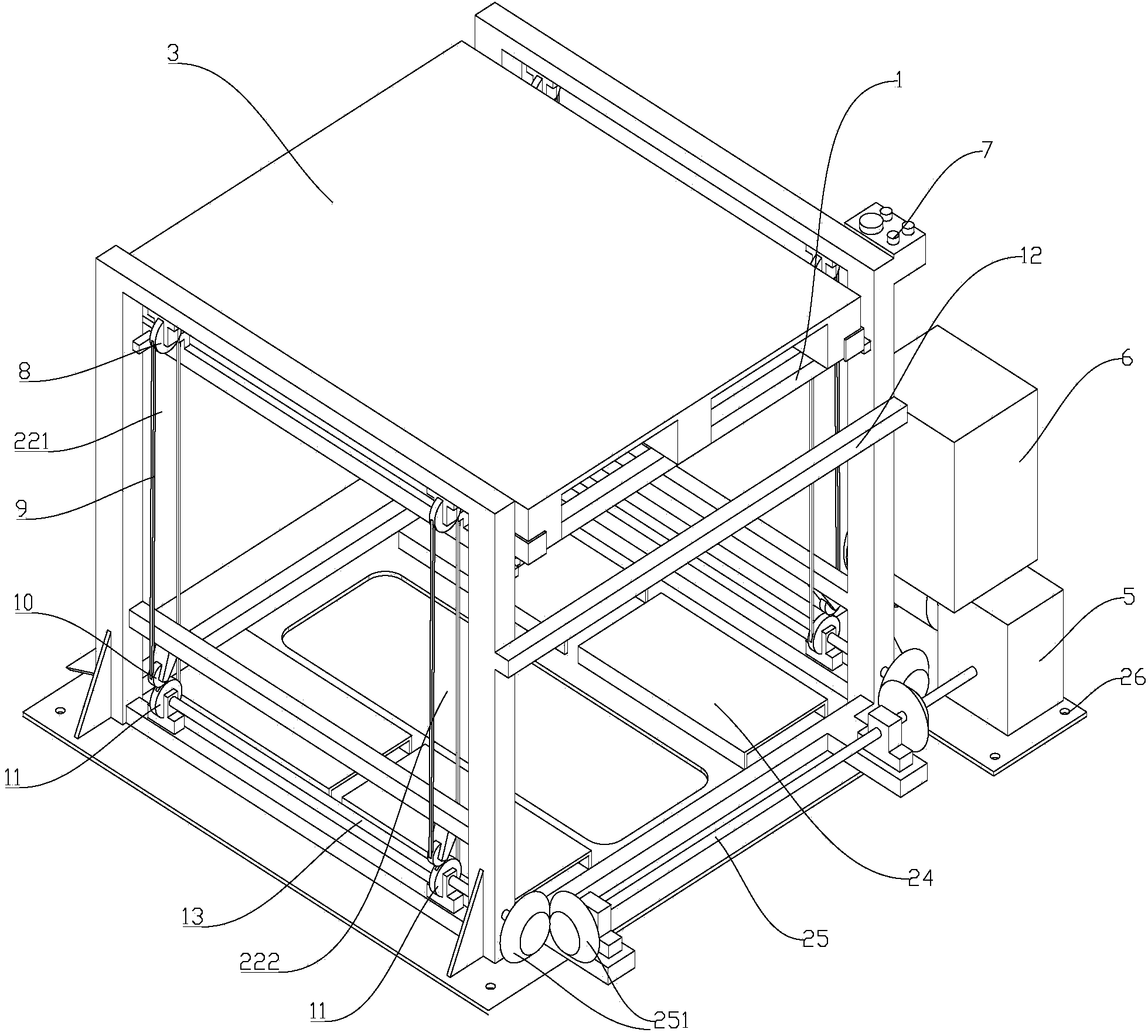

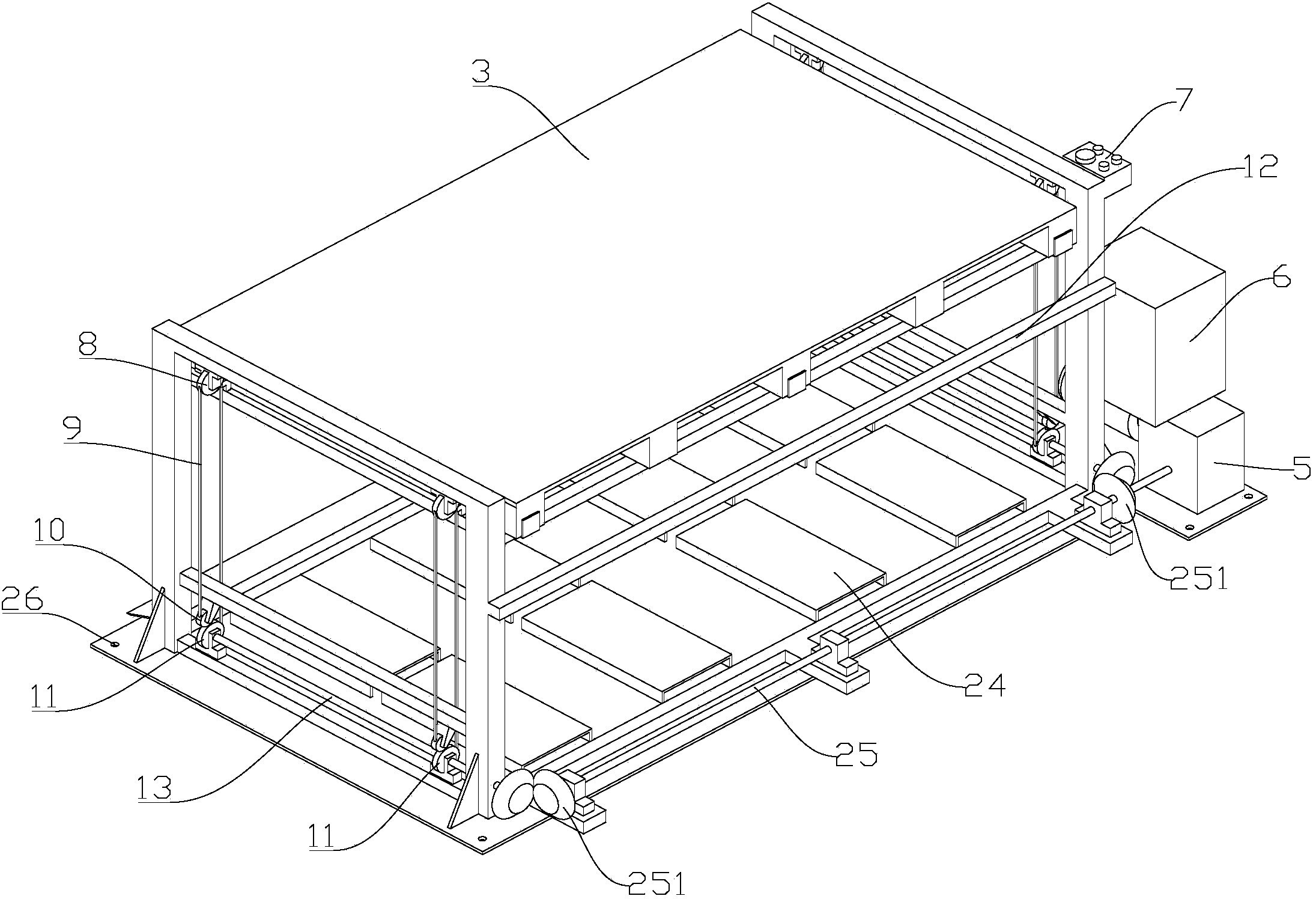

[0022] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0023] Such as figure 1 The preferred embodiment of a kind of suspended lifting equipment of the present invention shown includes the main frame 21 and the side frame 22 arranged on the chassis 2, and the main frame 21 and the side frame 22 in this embodiment A square tube profile of a standard common material is used as the main body material of the frame, but not limited thereto, one side of the main frame 21 and the side frame 22 is connected by a fixed rod 12, and the fixed rod 12 is set according to weighing requirements Quantity, between the main frame 21 and the side frame 22, there is an elevating table 1 that can move up and down. The main frame 21 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com