A queuing arrangement

A sorting device and guide rail plate technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of high manufacturing cost, unfavorable production development of enterprises, complex structure of clamping device, etc., and achieve the effect of simple structure and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

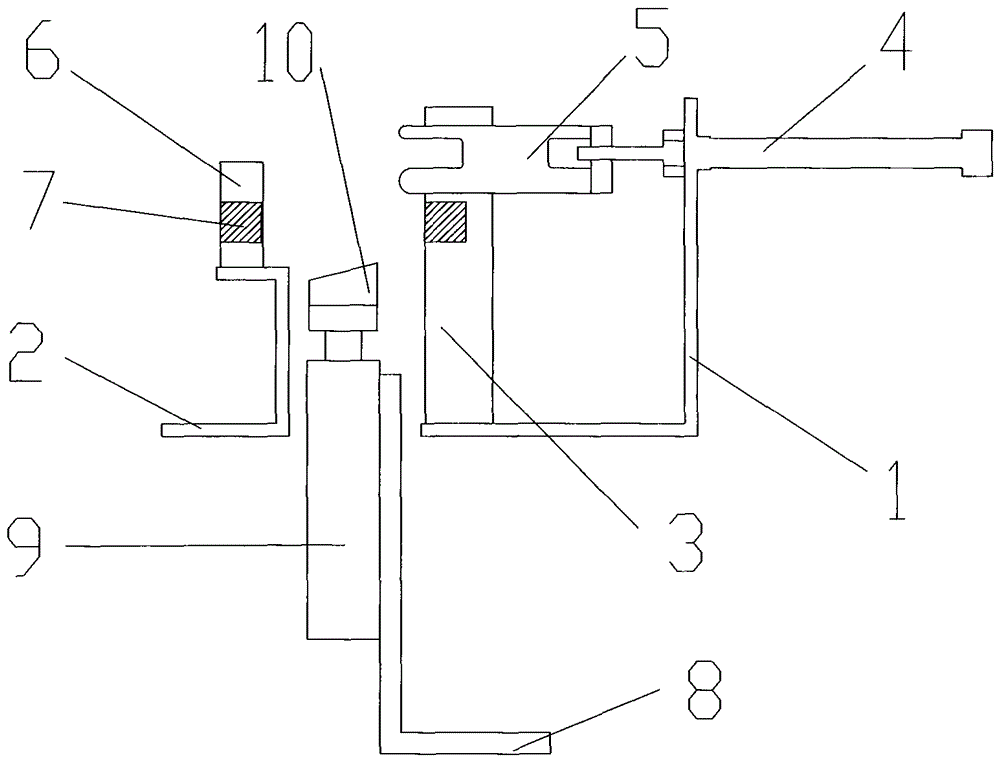

[0012] as attached figure 1 The said arranging device of the present invention comprises main L plate 1, auxiliary L plate 2, guide rail plate 3, cylinder 4, baffle plate 5, induction plate 6, photoelectric sensor 7, curved plate 8, biaxial cylinder 9 and the top splint 10; the main L plate 1 and the auxiliary L plate 2 are fixedly arranged on the same level, and there is a certain gap between the main L plate 1 and the auxiliary L plate 2; the main L plate 1 A guide rail plate 3 is fixed on the plate surface perpendicular to the axial direction, and a cylinder 4 is connected on the plate surface perpendicular to the radial direction; the telescopic rod portion of the cylinder 4 is connected with a baffle plate 5, and the baffle plate 5 can move axially on the guide rail plate 3; the top end of the auxiliary L plate 2 is fixedly prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com