Device for collecting die cut excess materials of labels

A technology for collecting device and residual material, applied in metal processing and other directions, can solve problems such as affecting product quality, increasing costs, and inaccurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

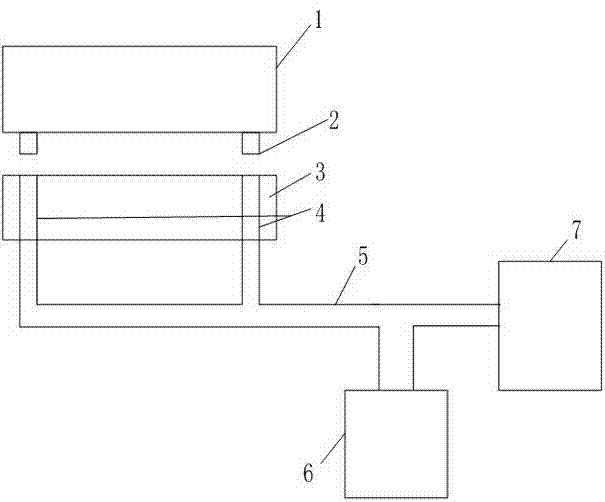

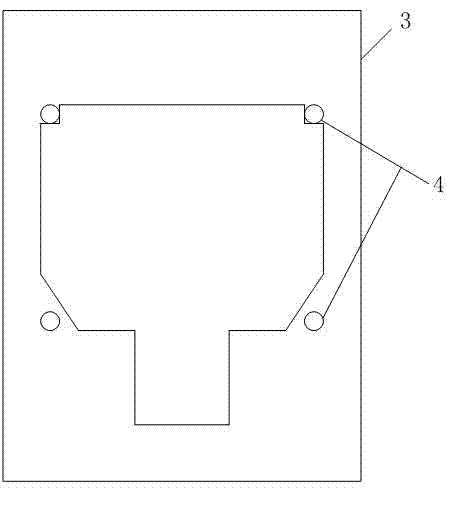

[0013] Such as figure 1 , figure 2 As shown, the collection device for label die-cutting residues includes a lower mold 3, an upper mold 1 matching the lower mold 3, a working groove is arranged on the lower mold 3, and positioning holes 4 are arranged around the working groove. The positioning holes 4 Arranged through the lower mold 3, the positioning hole 4 is connected to the air extraction device 6 through the communication pipe 5, the upper mold 1 is provided with a positioning block 2 matching the positioning hole 3, and the positioning hole 4 is collected with the remaining material through the communication pipe 5 The barrel 7 is connected to each other. By opening the positioning hole 4 around the working tank, the device can ensure that one end of the positioning hole 4 can be accurately pressed with the positioning block 2 on the upper mold 1, and at the same time pass through the other end of the positioning hole 4. The air extraction device 6 connected to the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com