Positioning clamp for automobile spoke

A technology for positioning fixtures and automobile wheels, which is applied to positioning devices, clamping, manufacturing tools, etc., and can solve problems such as difficulty in ensuring the position accuracy of each hole

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

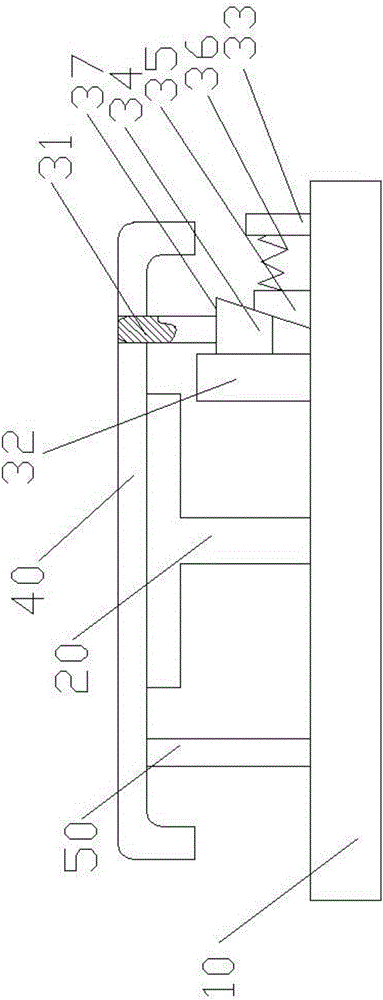

[0017] see figure 1 , as shown in the legend therein, an automobile spoke positioning fixture includes a base 10, a centering column 20 and a floating assembly, the centering column 20 is arranged in the middle of the base 10 and is generally T-shaped, and the floating assembly is arranged on the base 10, Including the floating pin 31, the first fixed block 32, the second fixed block 33, the first guide block 34, the second guide block 35 and the spring 36, the first fixed block 32 and the second fixed block 33 are respectively fixedly arranged on the base 10 And the two positions are opposite, the first guide block 34 is connected to the first fixed block 32 movably up and down, the floating pin 31 is connected to the first guide block 34, and the second guide block 35 is connected to the base 10 horizontally and movably. , the first guide block 34 and the second guide block 35 are connected by inclined plane guidance, one end of the spring 36 is connected to the second guide...

Embodiment 2

[0025] The rest is the same as the first embodiment, the difference is that on the opposite surfaces of the first guide block and the first fixed block, one of them is provided with a T-shaped slot, the other is provided with a T-shaped guide block, and the second guide block is provided with a T-shaped guide block. On the opposite surfaces of the block and the base, one of them is provided with a T-shaped slot, and the other is provided with a T-shaped guide block, and on the opposite surfaces of the first guide block and the second guide block, one of them is provided with a T-shaped slot, Another set of T-shaped guide blocks.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com