Air filter cartridge for compressed-air preparation for a compressed-air processing installation

A technology of air filter element and compressed air, applied in air treatment device, gas treatment, dispersed particle filtration, etc., can solve the problems of manufacturing cost and complex structure of air filter element, and achieve the effect of simplifying assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

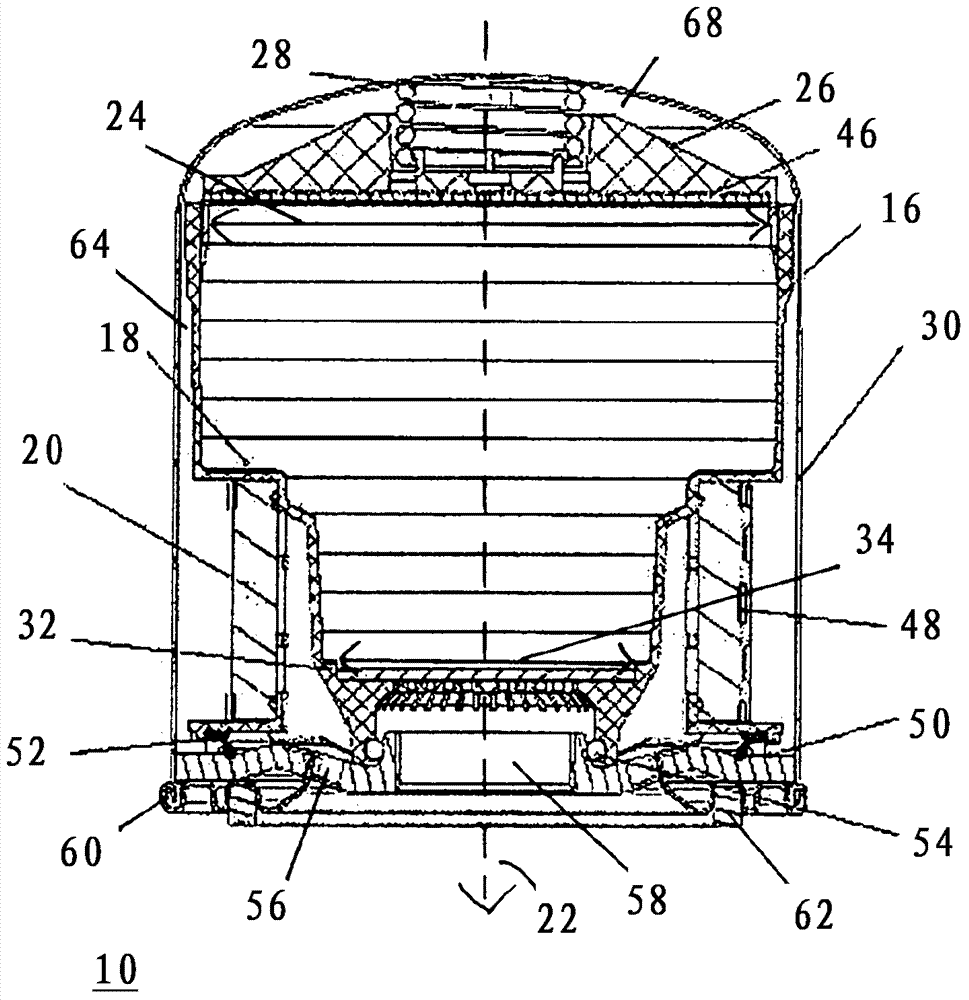

[0021] In the following figures, the same reference numerals designate the same or similar parts.

[0022] FIG. 1 shows a first air filter element of the prior art. The air filter insert 10 shown includes a desiccant container 16 which is arranged inside a pot-shaped housing 30 . Arranged within the desiccant container 16 is a desiccant 18 through which the compressed air to be processed flows in the axial extension direction 22 of the desiccant container 16 during the processing of the compressed air. The desiccant 18 present in the desiccant container 16 is fixed in the desiccant container 16 by the cover element 26 . The cover element 26 is prestressed in the direction of axial extension 22 by a spring element 28 supported on the housing 30 and is movable relative to the desiccant container 16 . In this way, the cover element 26 can be moved in the direction of axial extension 22 into the desiccant container 16 via the spring element 28 in order to fix the desiccant 18 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com