Method for preventing OPGW optical cable connected to substation structure from being broken by lightning strokes

A technology for substations and optical cables, which is applied in the field of OPGW optical cable access substation structure lightning protection and broken strands, can solve the problems of fusing, fiber core damage, construction, acceptance is not promulgated, etc., to achieve good electrical conductivity, appropriate wire lug area, The effect of eliminating the hidden danger of gap discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

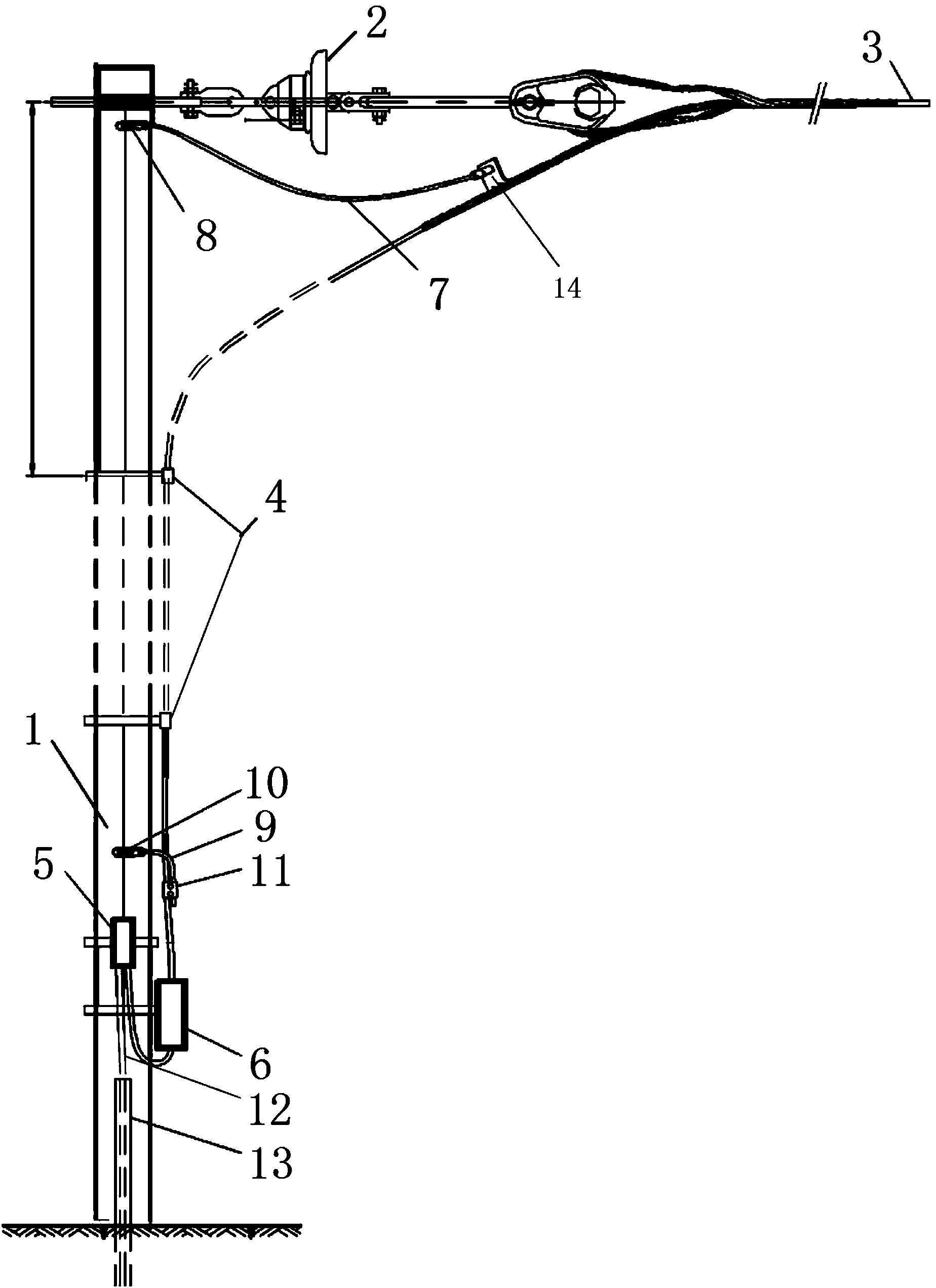

[0029] In order to better understand the present invention, the technical solutions of the present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

[0030] Such as figure 1 As shown, a method for OPGW optical cable access substation structure anti-lightning strike broken strands, it includes the following steps:

[0031] 1) Lay the down conductor of the OPGW optical cable 3 from top to bottom along the frame 1 (the OPGW optical cable 3 is fixedly connected to the upper end of the substation frame 1 through the insulator 2), and the down conductor of the OPGW optical cable 3 is fixed by a The clamp 4 is fixed on the frame 1; a fixed clamp 4 is installed on the frame 1 every 3-5m from top to bottom to ensure that the distance between the OPGW optical cable 3 down-lead and the frame 1 is more than 20mm; the fixed clamp at the top The installation position of 4 should ensure that the bending radius of the upper end of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com