A double-wire parallel-wound non-inductive thin-film platinum thermal resistance

A platinum thermal resistance and thin-film technology, which is applied in the field of thin-film platinum thermal resistance, can solve the problems of inaccurate temperature measurement, lack of anti-electromagnetic interference ability of thin-film platinum thermal resistance, and interference of temperature measurement accuracy of thin-film platinum thermal resistance, so as to eliminate electromagnetic Interference, elimination of adverse effects, and effects of electromagnetic compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

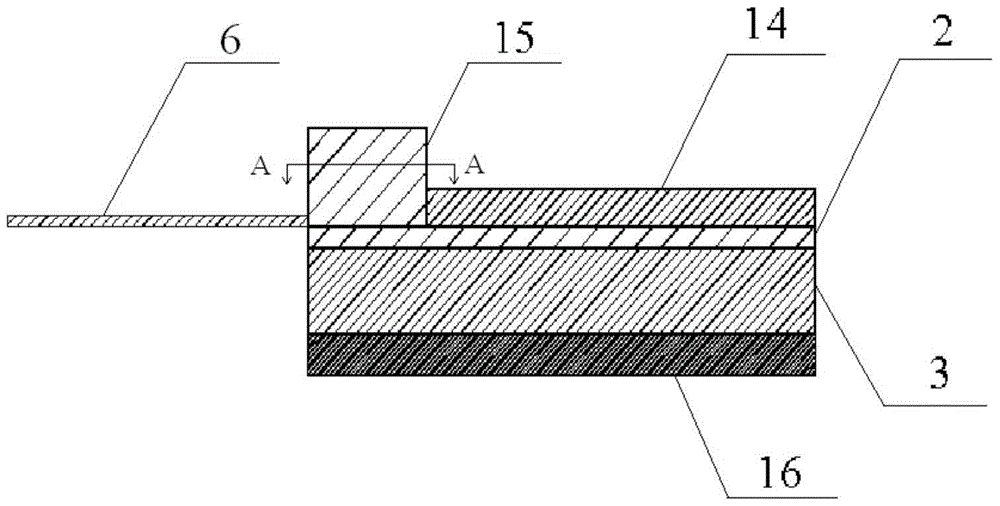

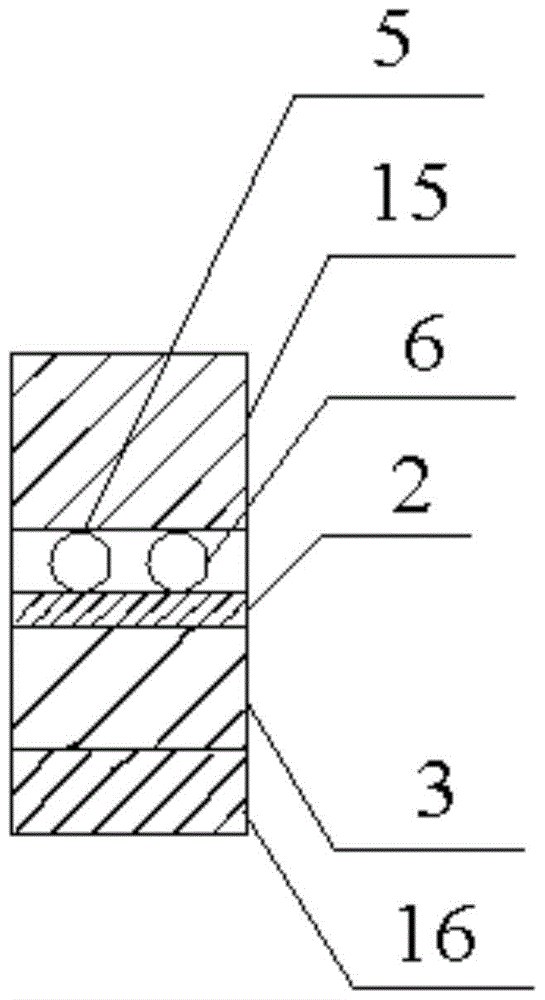

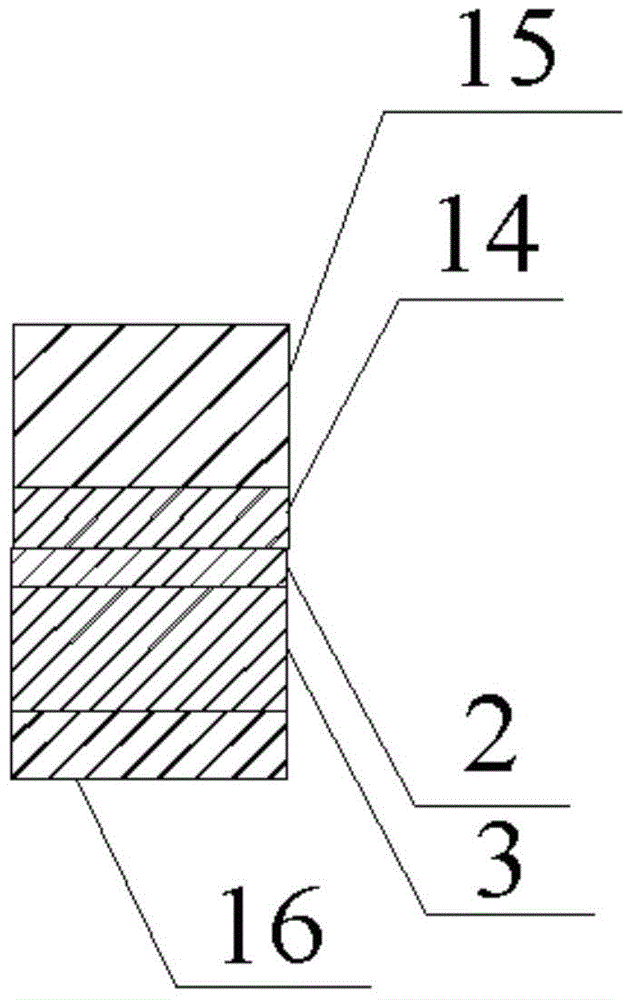

[0019] Embodiment 1: This embodiment is a double-wire parallel-wound non-inductive thin-film platinum thermal resistance, which includes encapsulating glass, metal platinum film 2, substrate 3, first lead 5 and second lead 6, and is characterized in that It also includes electrode paste connection 4;

[0020] Positive electrode 7, negative electrode 8 and thin-film platinum thermal resistance strip 9 are processed on metal platinum film 2; positive electrode 7 and negative electrode 8 are respectively connected with two thin-film platinum thermal resistance strips 9; The first resistance bar tap 10 and the second resistance bar tap 11 are provided at the part;

[0021] The metal platinum film 2 is deposited on the upper surface of the substrate 3; the first electrode hole 12 and the second electrode hole 13 are processed at the first resistance strip tap 10 and the second resistance strip tap 11, and the first electrode hole 12 and the second electrode hole 12 are processed. ...

specific Embodiment approach 2

[0034] Embodiment 2: This embodiment differs from Embodiment 1 in that: the material of the substrate 3 is an aluminum oxide ceramic substrate. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0035] Embodiment 3: The difference between this embodiment and Embodiment 1 or Embodiment 2 is that the lead wire 5 is made of platinum wire. Other steps are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com