Atmospheric chamber multi-diaphragm drivers for large blast wave simulators

A large-scale explosion wave and simulation device technology, which is applied in the field of multi-diaphragm actuators in atmospheric chambers, can solve the problems of uncontrollable time required for the gas in the drive tube to empty, high site conditions, and unsatisfactory experimental requirements. Low cost, precise and controllable operation, controllable diaphragm opening quantity and position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to facilitate those skilled in the art to understand and implement the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

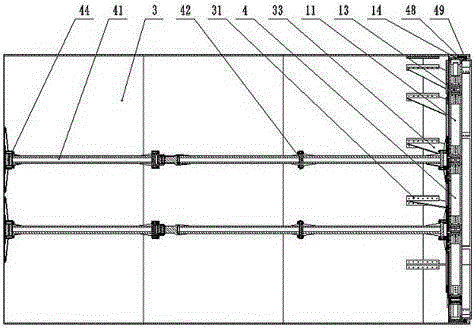

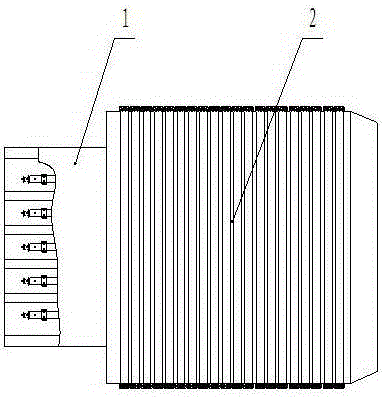

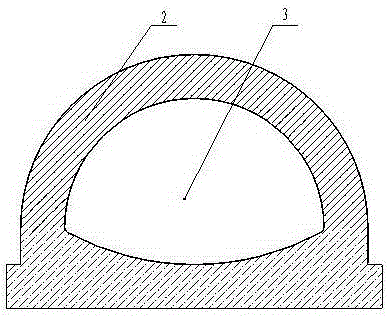

[0024] Such as figure 1 , figure 2 As shown, an atmospheric chamber multi-diaphragm driver used for a large blast wave simulation device, said atmospheric chamber multi-diaphragm driver includes a buttress-type reaction wall 1, a high-pressure section 2, a diaphragm and a high-pressure isolation structure 4; the buttress type reaction wall 1 is located at the starting end of the high-pressure section 2, and the diaphragm and the high-pressure isolation structure 4 are located at the outlet end of the high-pressure section 2; the high-pressure gas chamber 3 is formed by the high-pressure section 2 , diaphragm and high-pressure sealing structure 4 and buttress type reaction wall 1 constitute a sealed high-pressure vessel; as image 3 As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com