Damping coupler

A coupling and damping technology, which is applied in the direction of couplings, elastic couplings, mechanical equipment, etc., can solve the problems of inconvenient installation and disassembly, poor precision, poor alternating load and impact load, etc., and achieve installation and disassembly Convenience, significant shock absorption effect, good tightening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

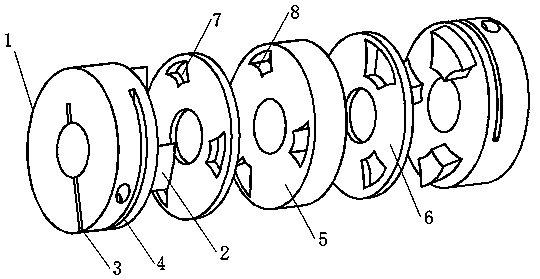

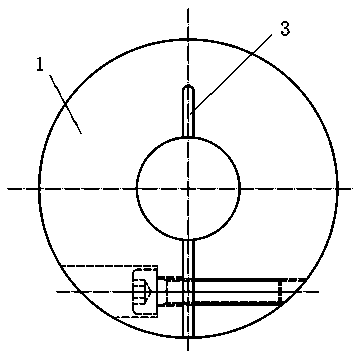

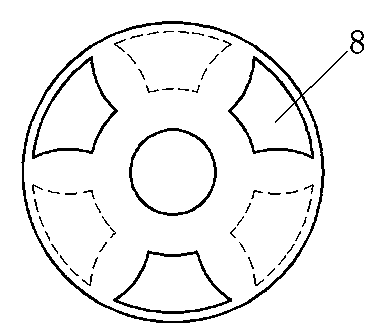

[0025] Such as Figure 1-3 As shown, the technical solution of the present invention is: a damping coupling, comprising two clamping sleeves 1 and an intermediate body, the two clamping sleeves are respectively installed on both sides of the intermediate body,

[0026] The clamping sleeve includes a circular body 1 and a plurality of metal claws 2 extending in the axial direction along the end face of the circular body 1 and arranged in an array along the circumferential position of the end face. The axial direction is formed between two adjacent metal claws 2 The circular body 1 passes through its central position and radially is provided with a gap groove 3 from the left end surface to the right end surface, the width is 2mm higher than the radius of the circular body 1, and the side surface of the circular body 1 is provided with a through The tightening bolt passing through the gap groove 3 is provided with a radial slot 4 with a width of 2 mm higher than the radius of the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com