Auxiliary power output structure of diesel engine

A technology of auxiliary power and output structure, applied in the direction of machines/engines, mechanical equipment, etc., can solve the problems of high failure rate of gear locking, complex lubricating oil circuit, and large number of parts, and achieve simple lubrication, simple structure, and The effect of a small amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

[0023] Unless otherwise expressly stated otherwise, throughout the specification and claims, the term "comprising" or its transformations such as "including" or "including" will be understood to include the stated elements or components, and not Other elements or other components are not excluded.

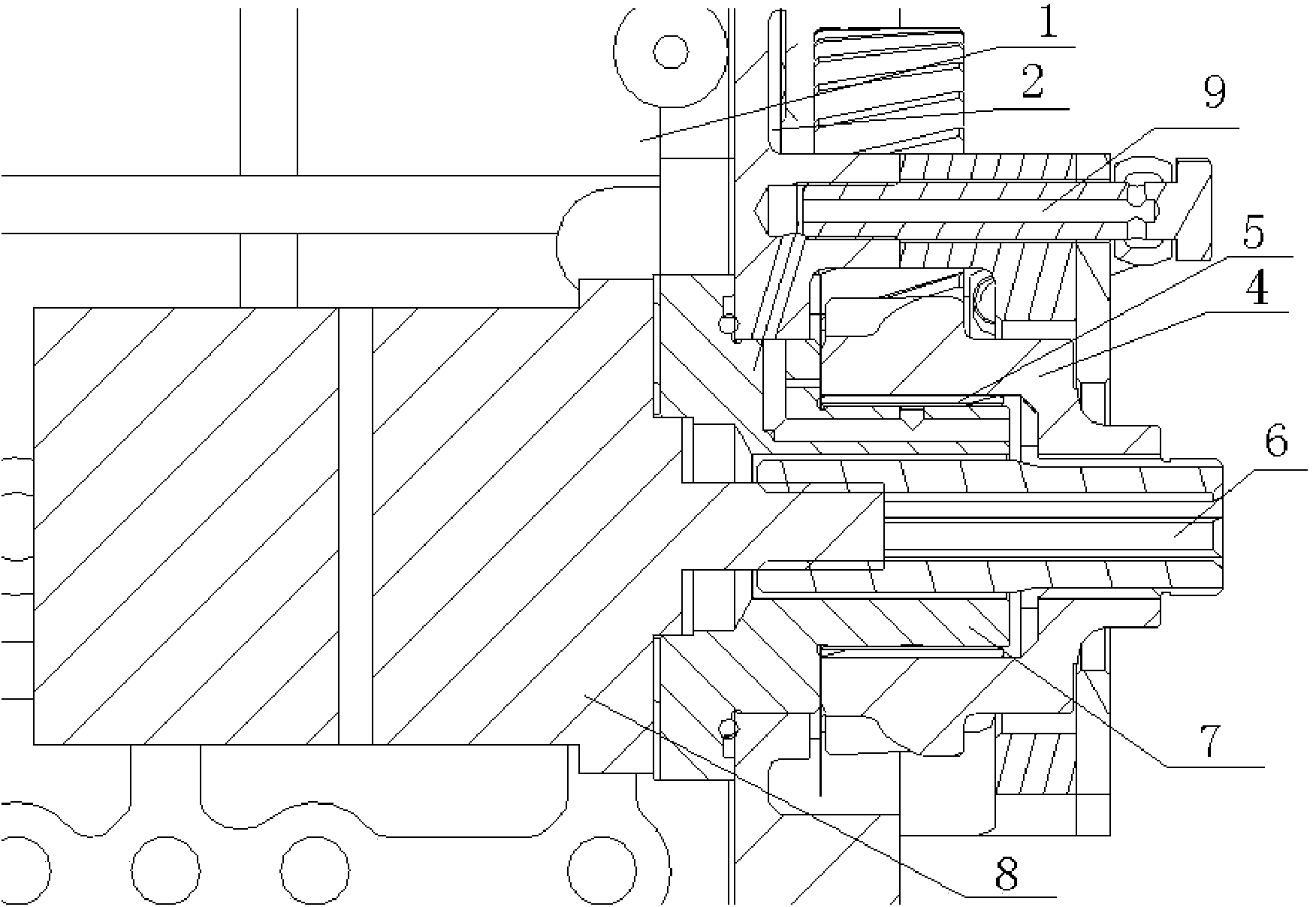

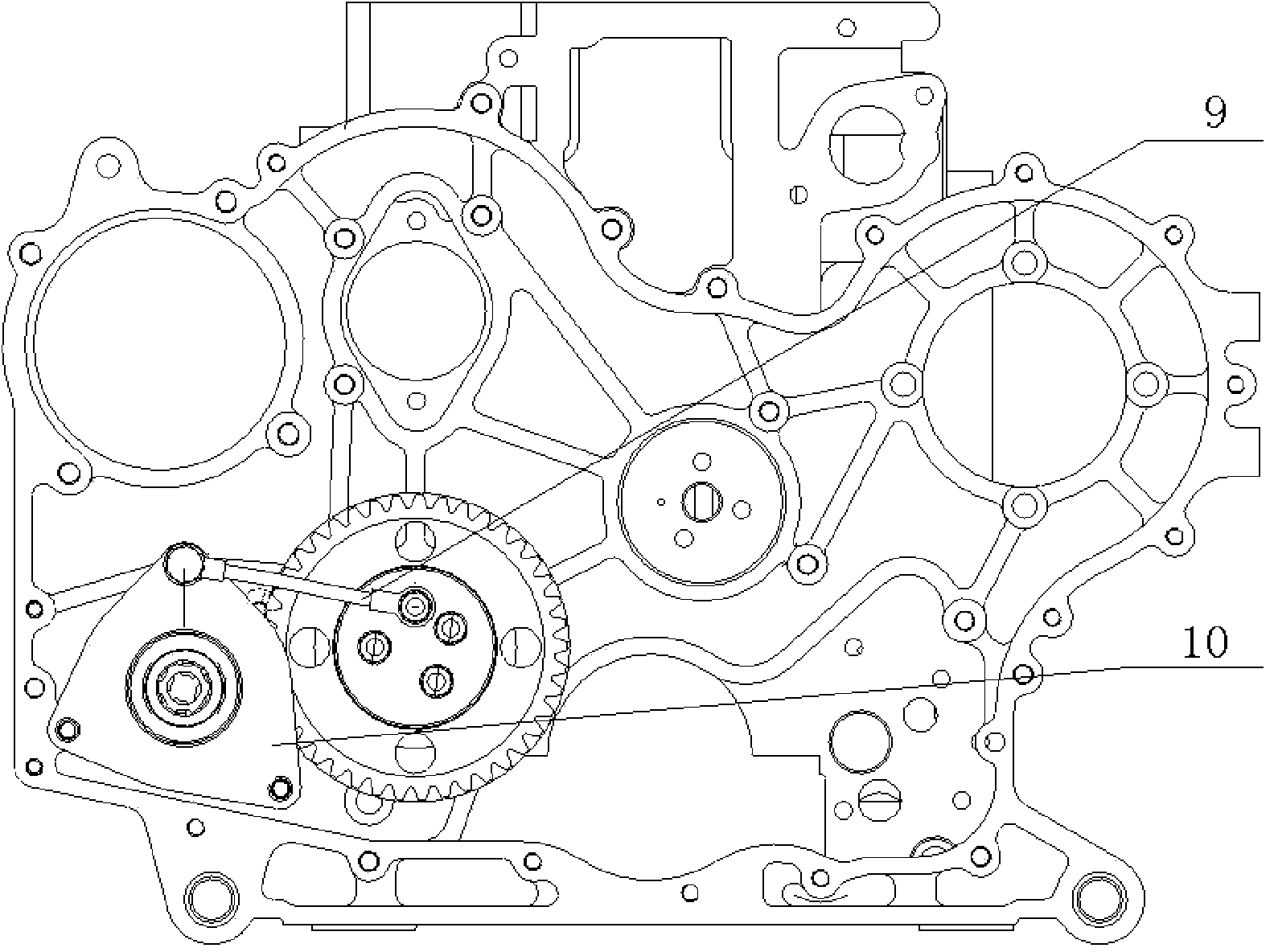

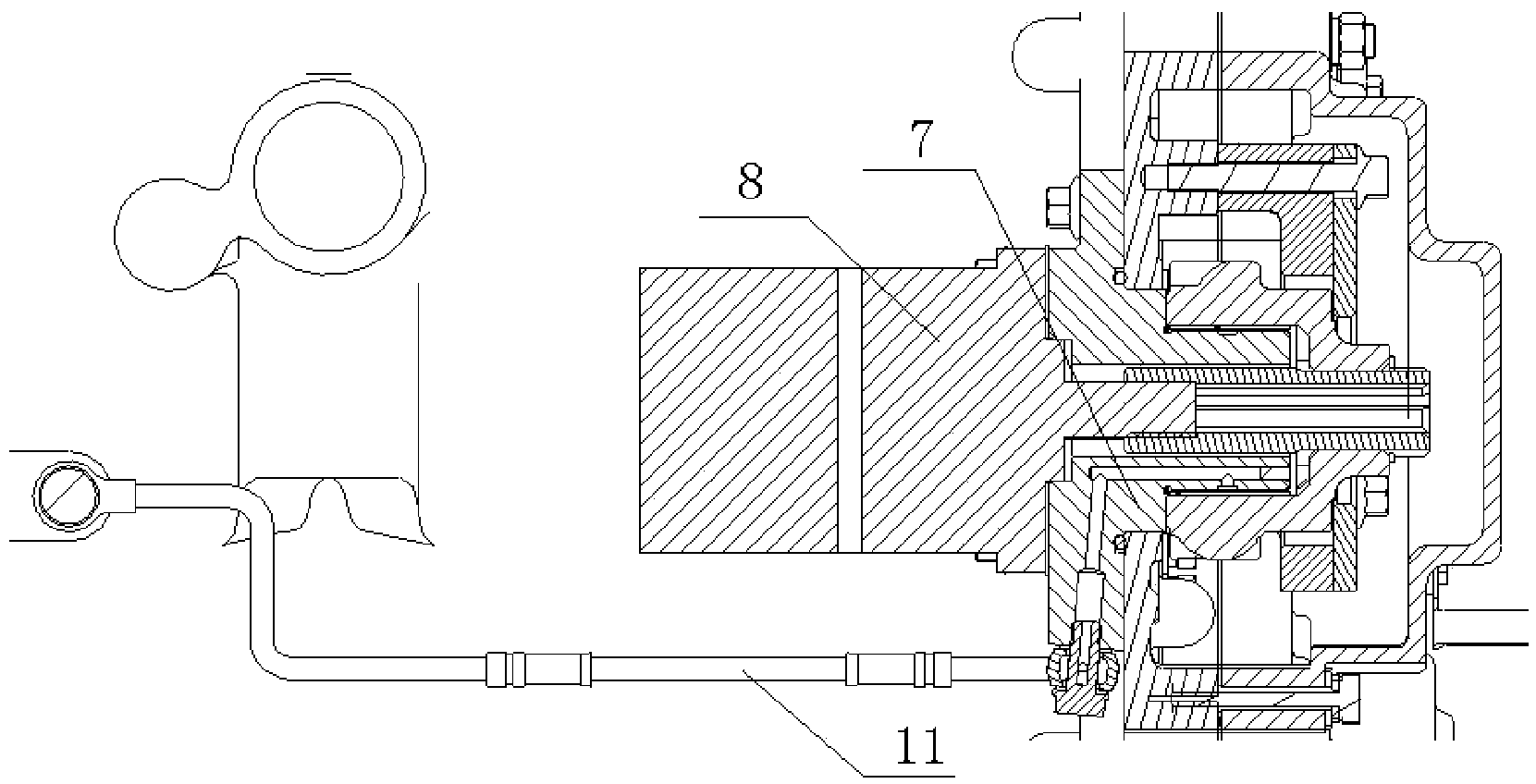

[0024] Such as Figure 4 and Figure 5 As shown, a diesel engine auxiliary power output structure according to a specific embodiment of the present invention is used to install a hydraulic pump (not shown in the figure, please refer to figure 1 ) And provide power to the hydraulic pump. The gear chamber of the diesel engine and the gear chamber cover have a mounting interface (not shown in the figure). The auxiliary power output ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com