Infrared Suppressor and Its Infrared Suppression Method for Exhaust System of Helicopter Turboshaft Engine

A turboshaft engine, infrared suppression technology, applied in the direction of machines/engines, engine components, exhaust devices, etc., can solve the problem of difficulty in the influence of infrared radiation of engine exhaust devices, and achieve the purpose of reducing exhaust temperature, reducing infrared radiation, reducing The effect of low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

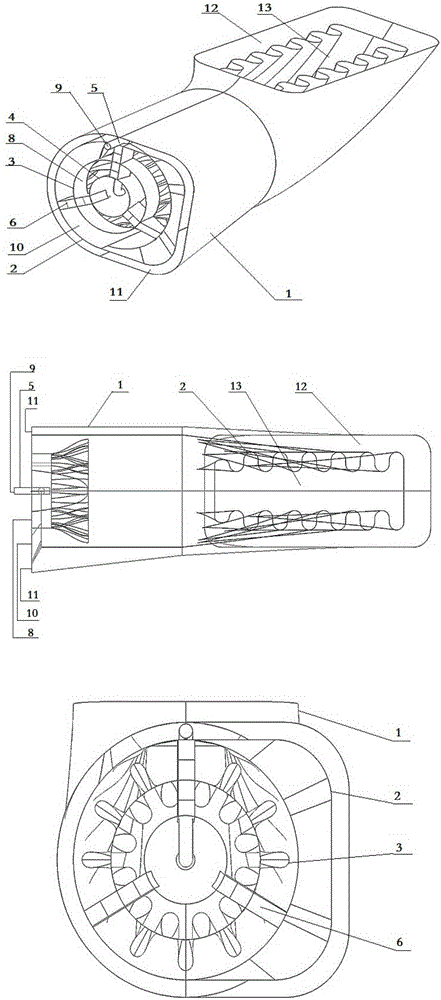

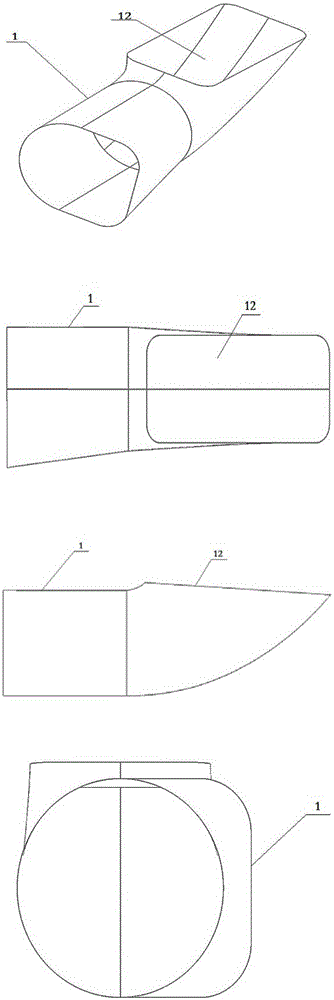

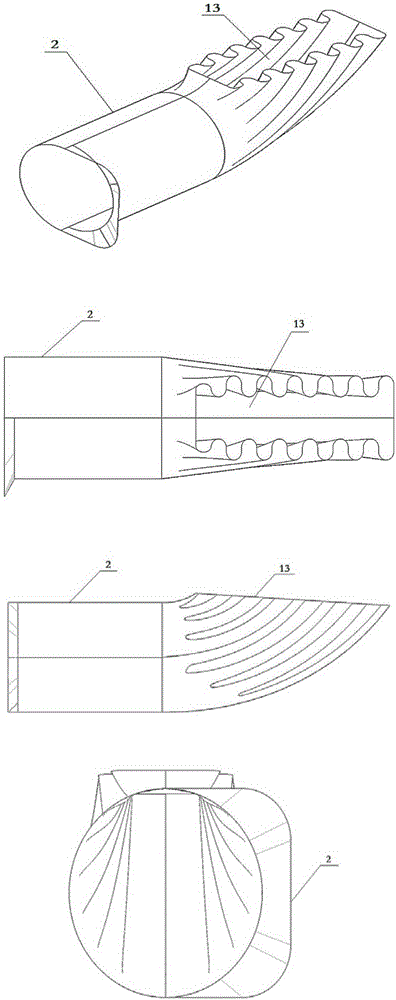

[0032] Please refer to Figure 1 to Figure 10 As shown, the infrared suppressor of the helicopter turboshaft engine exhaust system of the present invention consists of a binary curved fairing 1, a binary curved lobe injection mixing tube 2, a first-stage circular row of wave lobe nozzles 3, an exhaust inner cone 4, Sand control residual air conduit 5 and hollow support plate 6 are formed. One side of the three hollow support plates 6 is connected to the wall surface of the exhaust inner cone 4 by welding, the sand control residual gas inlet 9 and the sand control residual gas outlet 14 are arranged on the sand control residual gas conduit 5, and the sand control residual gas conduit 5 is penetrated In one of the hollow support plates 6, it is further connected with the hollow support plate 6, and the sand control residual air inlet of the sand control residual air conduit 5 extends out of the hollow support plate 6 and the outer side of the exhaust inner cone 4, and the sand c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com