Anti-bursting device for worm gear box of turbosupercharger

A turbocharger and turbo box technology, which is applied in the direction of machines/engines, engine components, mechanical equipment, etc., can solve the problems of installation and disassembly of turbochargers, inconvenient maintenance of components, increased difficulty of casting turbo boxes, and quality of turbo boxes Large and other problems, to achieve the effect of easy replacement and maintenance, convenient disassembly and assembly, and meet the requirements of versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

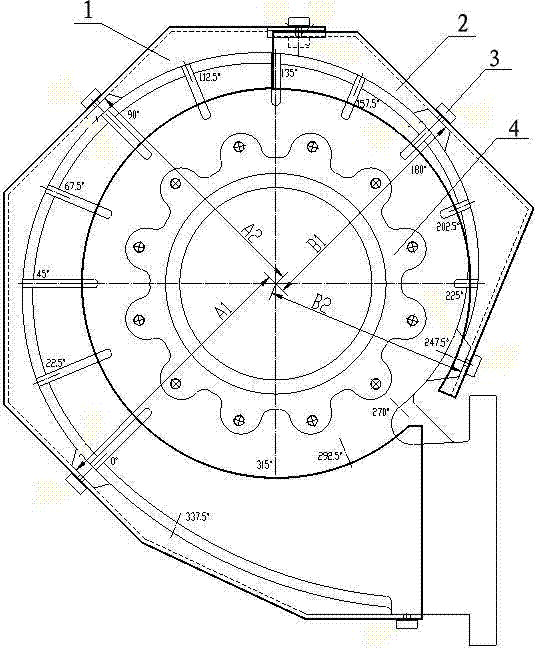

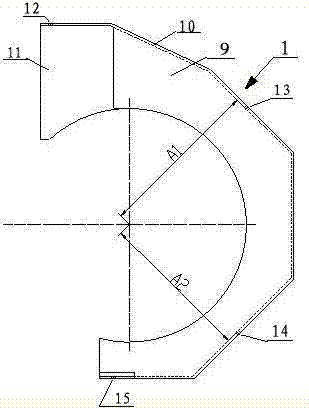

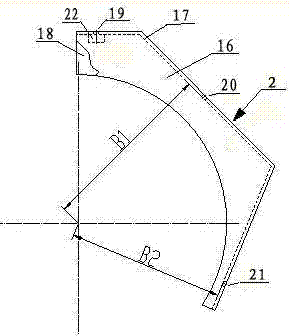

[0020] An explosion-proof device for a turbocharger turbine box, including an upper protective cover 1, a lower protective cover 2, a heat-resistant anti-loosening screw 3 and a turbo box 4 to be protected. The turbo box 4 is provided with a height-adjustable The first locating platform 5, the second locating platform 6, the third locating platform 7 and the fourth locating platform 8 are convenient for positioning and connection, and the upper protective cover 1 and the lower protective cover 2 are fixed on the turbine box 4 by heat-resistant and anti-loosening screws 3 On the above four positioning platforms, the upper protective cover 1 is composed of the first upper side plate 9, the first top plate 10, and the first lower side plate 11, wherein the first upper side plate 9 and the first lower side plate 11 is connected to both sides of the first top plate 10, and the first top plate 10 is sequentially provided with four first openings 12, second openings 13, third openings...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Nominal diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com