Positive pressure air pipeline drainage and rust scale discharging device

A technology of compressed air pipelines and control devices, applied in safety devices, drainage, ventilation of mines/tunnels, etc., can solve problems such as rust cannot be discharged, and achieve the effect of ensuring safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

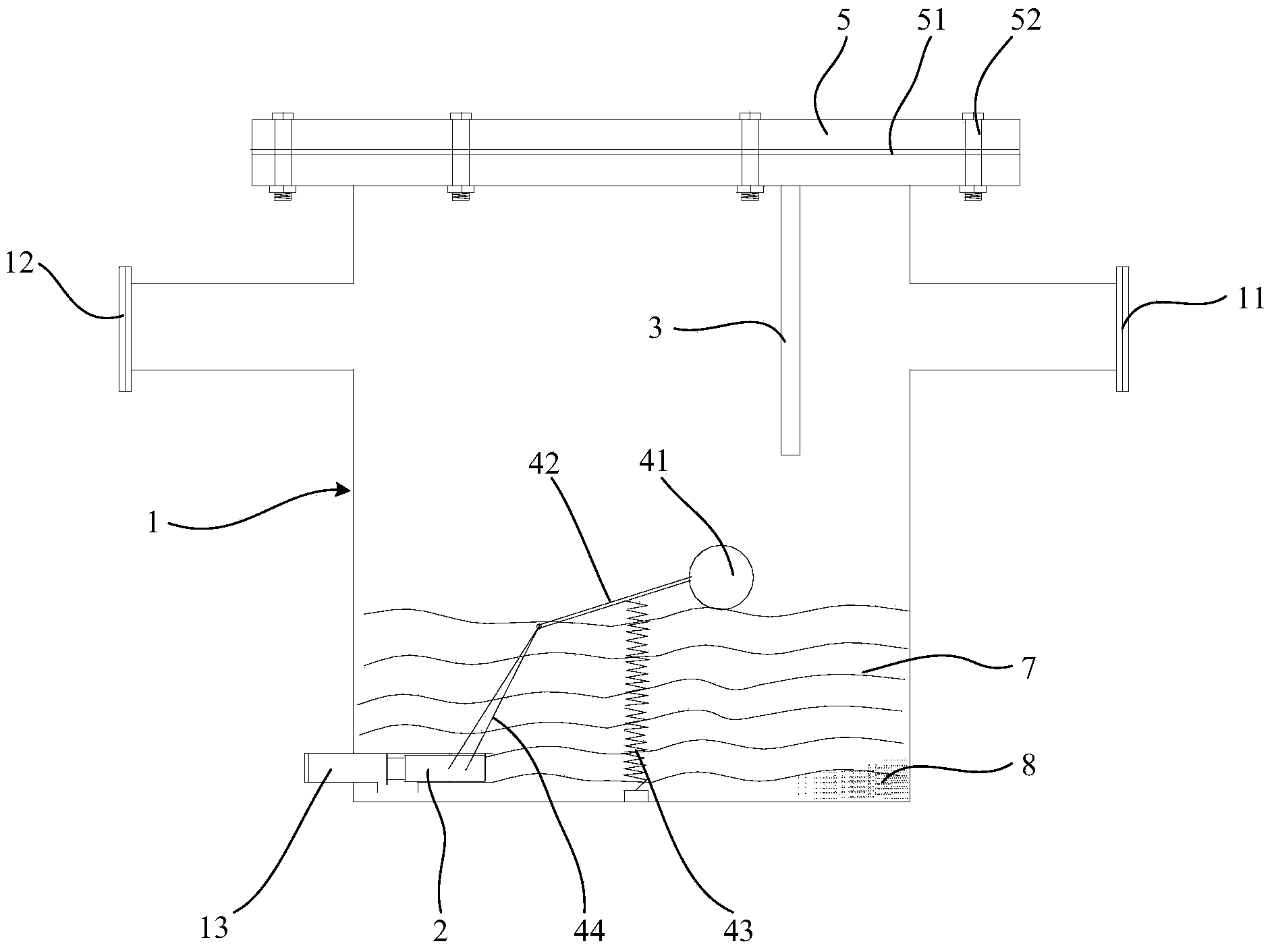

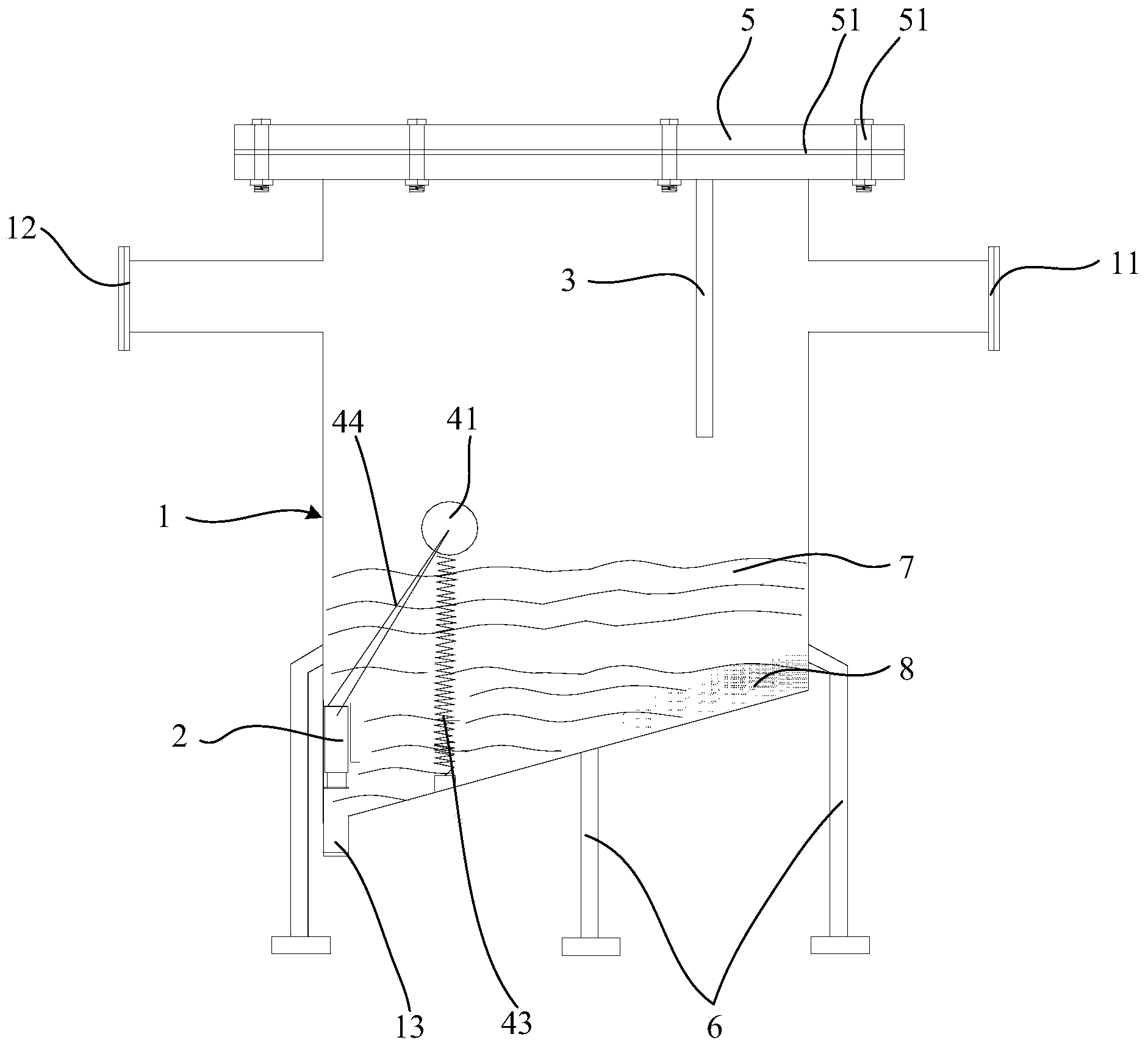

[0034] figure 1 It is a schematic structural diagram of a positive pressure air pipeline water discharge and scale removal device provided by an embodiment of the present invention. Such as figure 1 As shown, the positive pressure air pipeline water discharge and scale removal device provided in this embodiment includes: a tank body 1, a positive pressure air inlet 11 and a positive pressure air outlet 12 arranged on the upper part of the side wall of the tank body 1, and a positive pressure air outlet 12 arranged on the lower part of the tank body 1 The drain port 13, the drain valve 2 arranged on the drain port 13 and the control device for controlling the opening or closing of the drain valve 2 according to the water level in the tank body 1.

[0035] A baffle 3 is arranged inside the tank body 1 , and the baffle 3 is located between the positive pressure air inlet 11 and the positive pressure air outlet 12 and is close to the positive pressure air inlet 11 .

[0036] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com