Assembled type gridding shearing wall structural system and construction technology of assembled type gridding shearing wall structural system

A shear wall, prefabricated technology, applied in the direction of walls, building components, building structures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

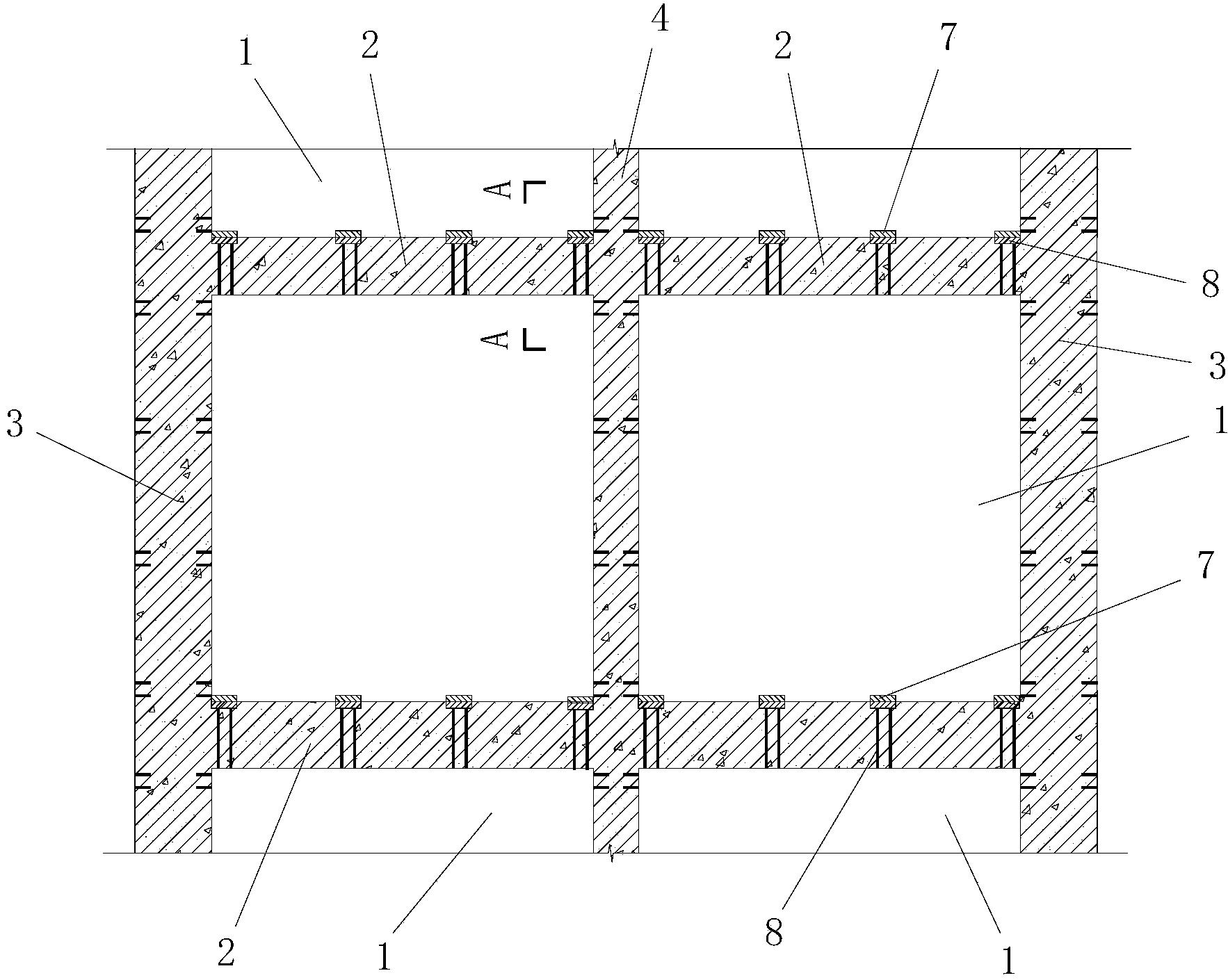

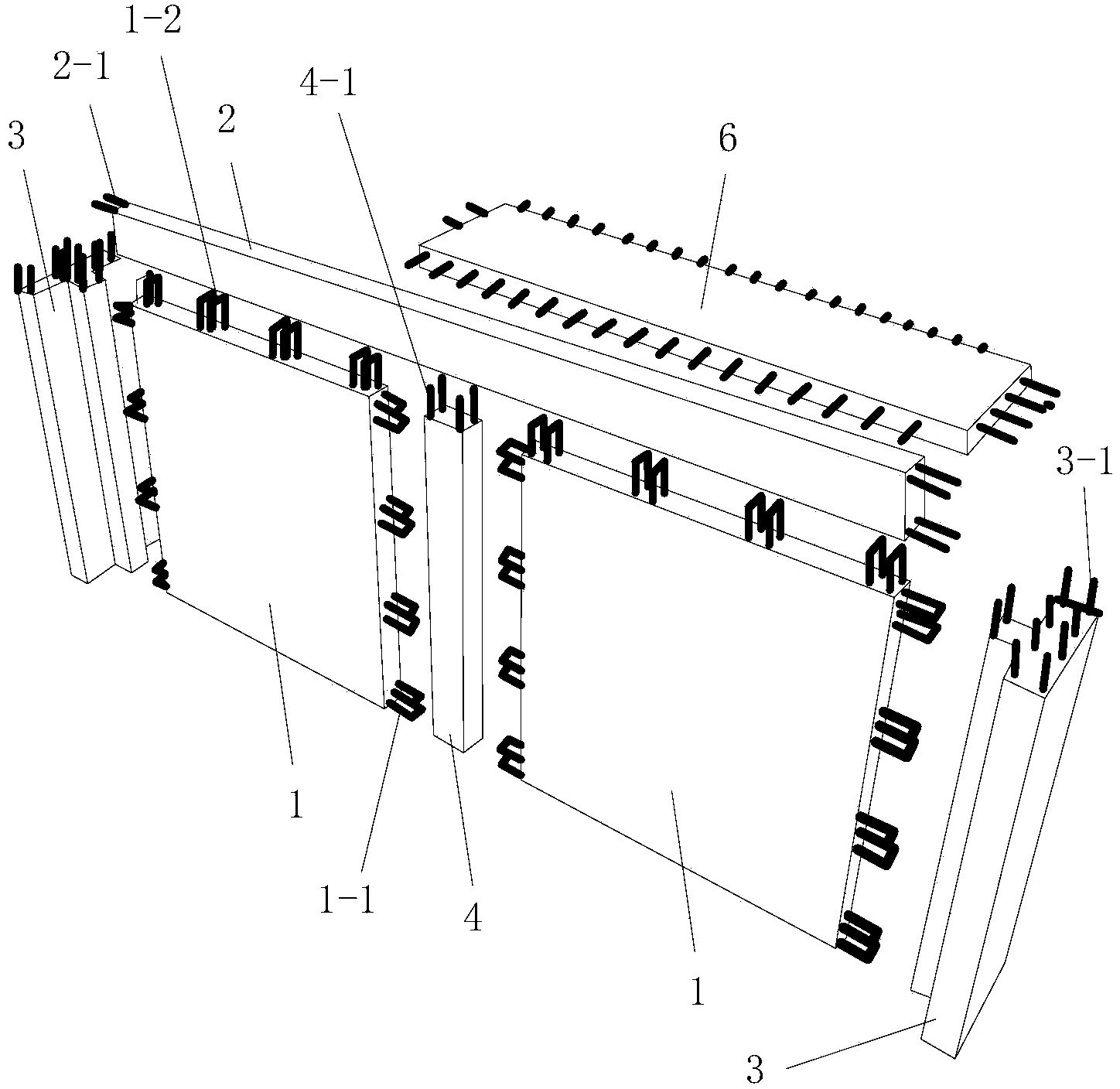

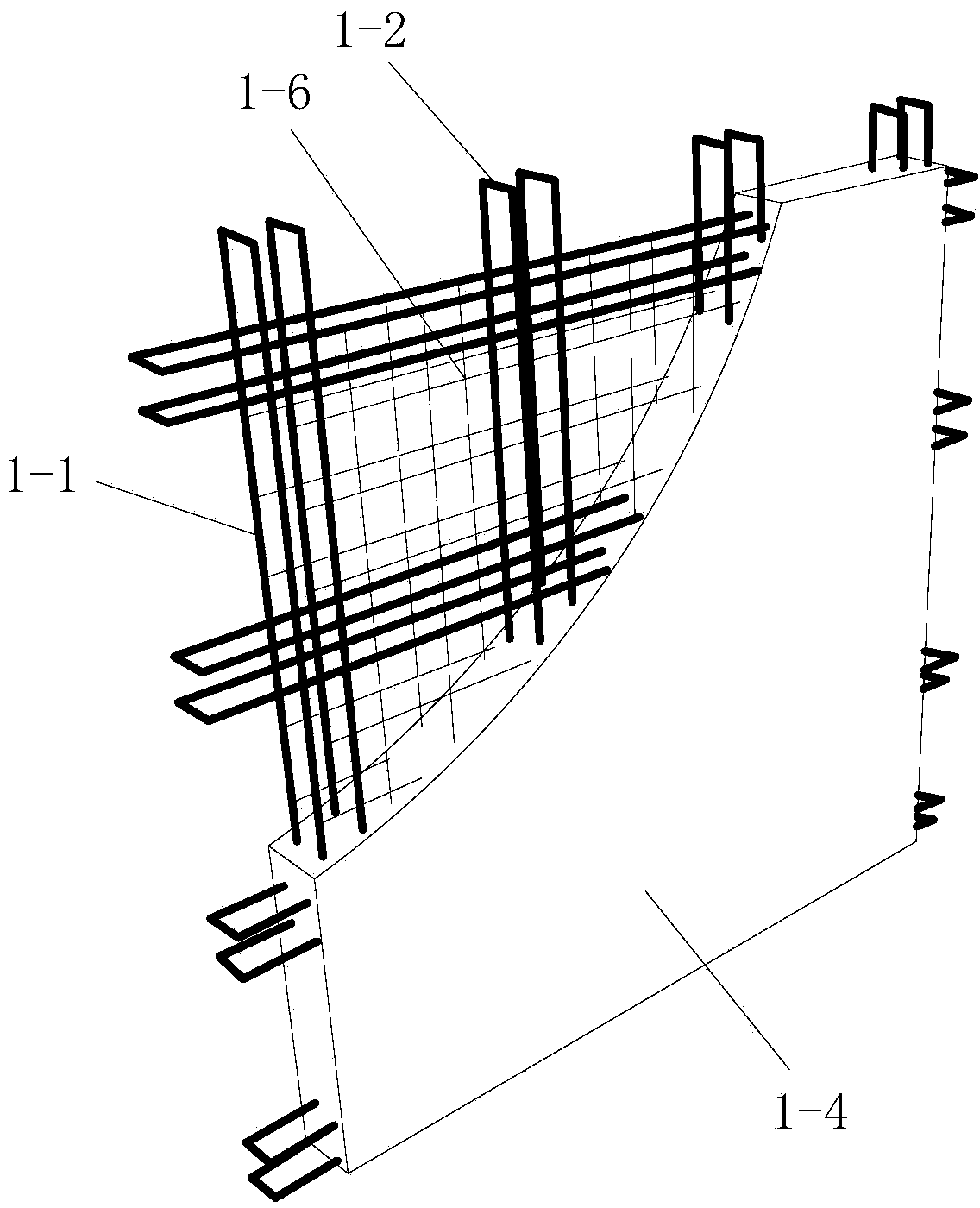

[0071] Such as figure 1 , figure 2 and image 3 As shown, the prefabricated grid shear wall structure system of the present invention includes multi-layer shear wall panels arranged from top to bottom, the structure and size of the multi-layer shear wall panels are the same and they are all laid on the same vertical plane.

[0072] The shear wall panels of each layer include a shear wall body formed by splicing a plurality of prefabricated grid shear walls 1 arranged on the same horizontal plane, and the plurality of prefabricated grid shear walls 1 are connected into a An integrated upper constraining concealed beam 2 and two vertical edge constraining members 3 that limit the left and right sides of the shear wall respectively, and multiple prefabricated grid shear walls 1 are arranged on the same vertical plane and it is laid out from left to right, and two adjacent prefabricated grid shear walls 1 are connected by connecting concealed columns 4 . The plurality of pref...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com