A chenille yarn cutting device

A technology of chenille machine and velvet yarn, which is applied in the direction of yarn, textiles and papermaking, etc. It can solve the problems of increased yarn waste, easy wear of blades, blunt blades, cutting and immovable velvet, etc., so as to reduce labor intensity and prolong service life. Lifespan, the effect of increasing the time interval

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

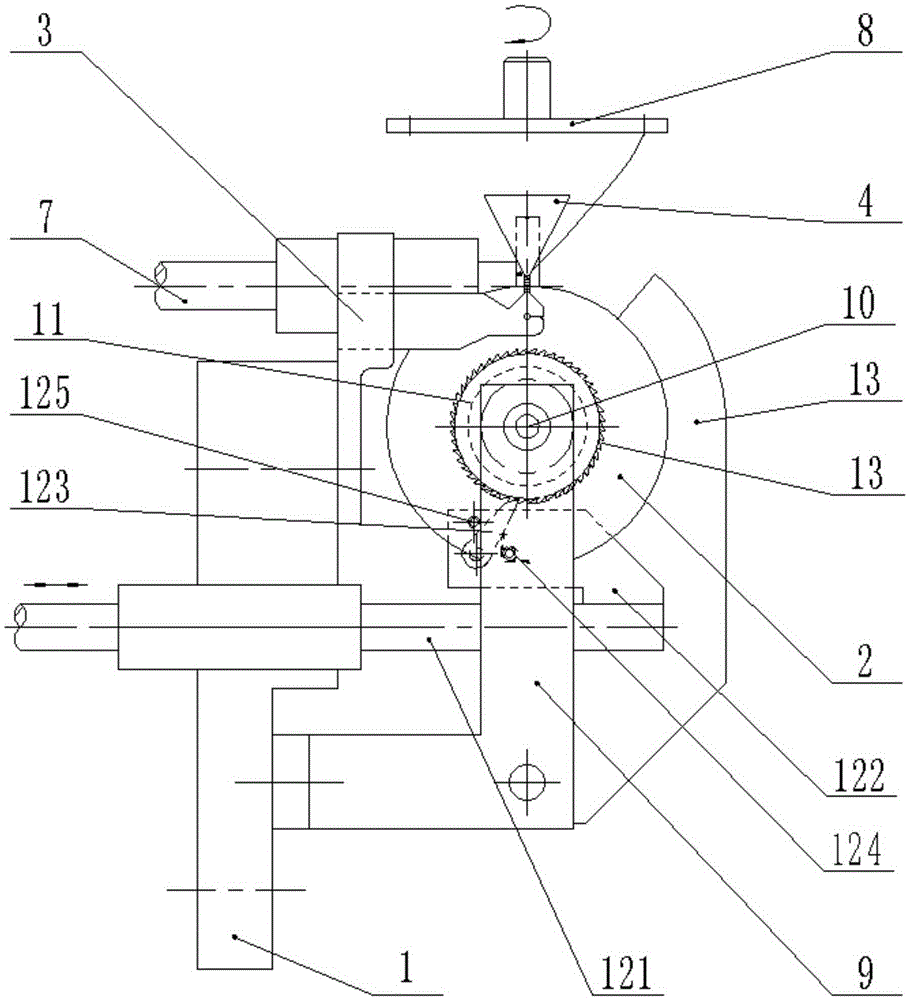

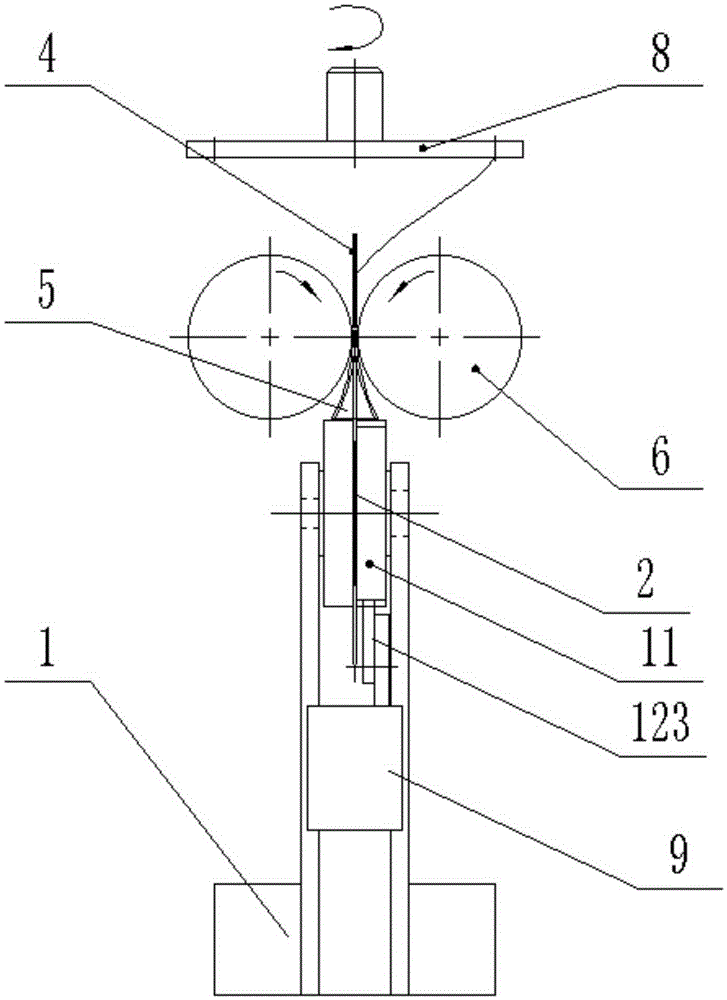

[0015] like figure 1 As shown, a velvet yarn cutting device for a chenille machine comprises a spinning frame, a base 1 is provided on the spinning frame, a blade for cutting velvet yarn is movable on the base 1, and a cutting blade is provided on the base 1. 4 seats 3 of distance sheets, the 4 seats 3 of cut distance sheets comprise a connecting portion, and the connection portion is provided with two installation pieces oppositely arranged in a figure-eight shape, and the two installation pieces are respectively provided with cut distance sheets 4, and the two cut distance pieces Sheets 4 are oppositely arranged in a herringbone shape. The spacer briquetting block 5 is provided between the two mounting pieces on the 4 seat 3 of the distance piece. On the spinning machine frame, a roller piece 6 that drives the pile yarn coil to move downwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com