Quaternary compound spinning method and product

A composite spinning and composite yarn technology, applied in the field of composite yarn, can solve the problems such as rare and few research and development, and achieve the effect of good application value and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

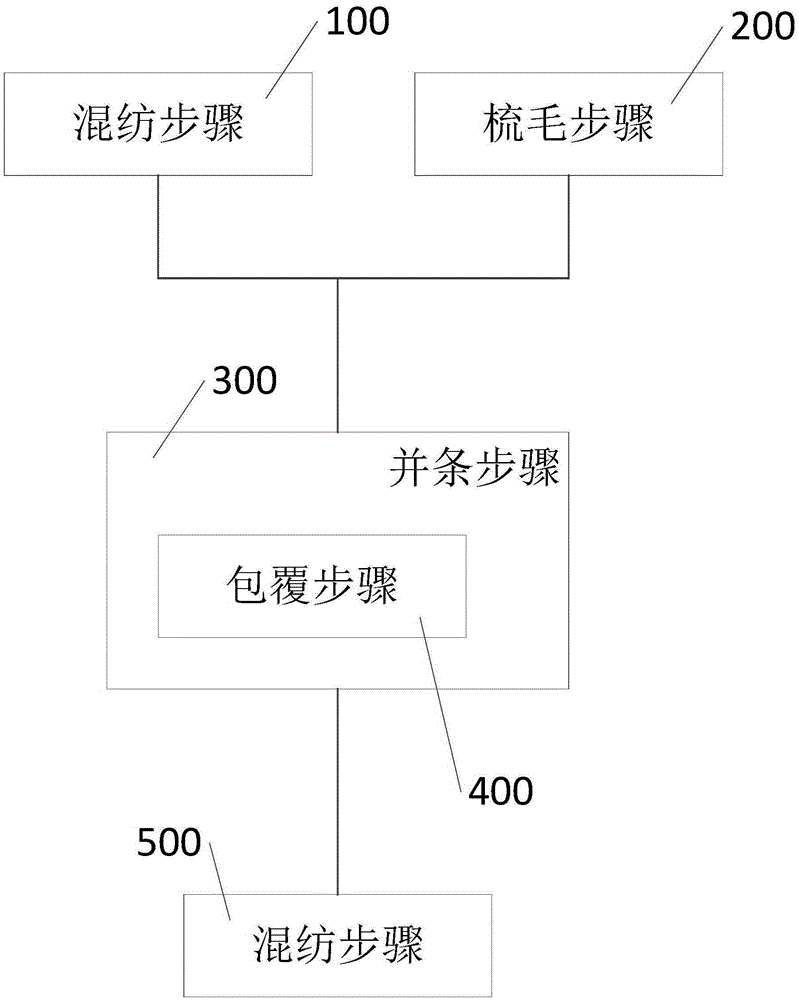

[0024] Composite spinning methods such as figure 1 shown, including the following specific steps:

[0025] Blending step 100: use cotton spinning equipment to evenly mix aloe fiber and cotton-type hydrophilic polyester to make a mixed sliver of uniform length, which simplifies equipment requirements. The cotton spinning equipment used includes a combined opening and cleaning machine and a carding machine. The combined opening and cleaning machine opens and removes the aloe fiber and cotton-type hydrophilic polyester respectively and mixes them to make cotton rolls with a certain weight, certain length and uniform size. The carding machine opens and separates the cotton rolls. and impurity removal, so that all the coiled cotton loops become basically straight single fibers, and in this process, remove the broken seeds, impurities and short fibers left over from the cleaning process, and then integrate cotton slivers of a certain size , Stored in the cotton cylinder for use in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com