Stocker for cooking, drive mechanism of stocker and quick clutch batching system

A technology of driving mechanism and batching system, which is applied in the direction of packaging, etc., can solve problems such as unguaranteed sanitary conditions, difficult cleaning and replacement of parts, difficult maintenance and repair, etc., and achieves the effect of easy cleaning and maintenance, convenient maintenance, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in detail below with reference to the accompanying drawings and embodiments. In the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

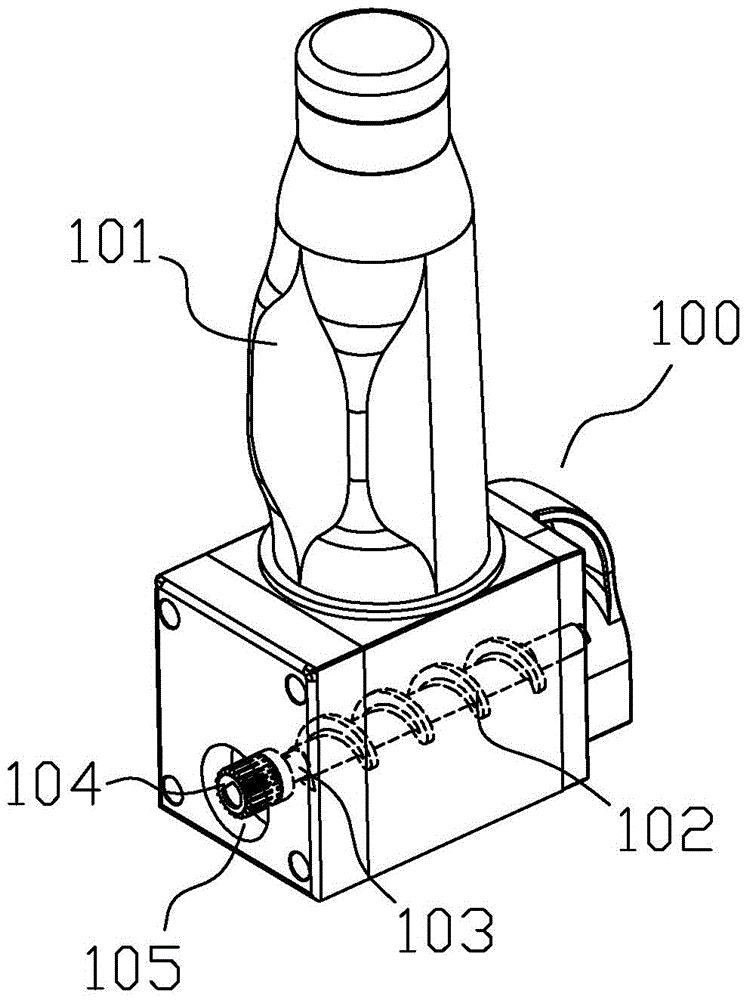

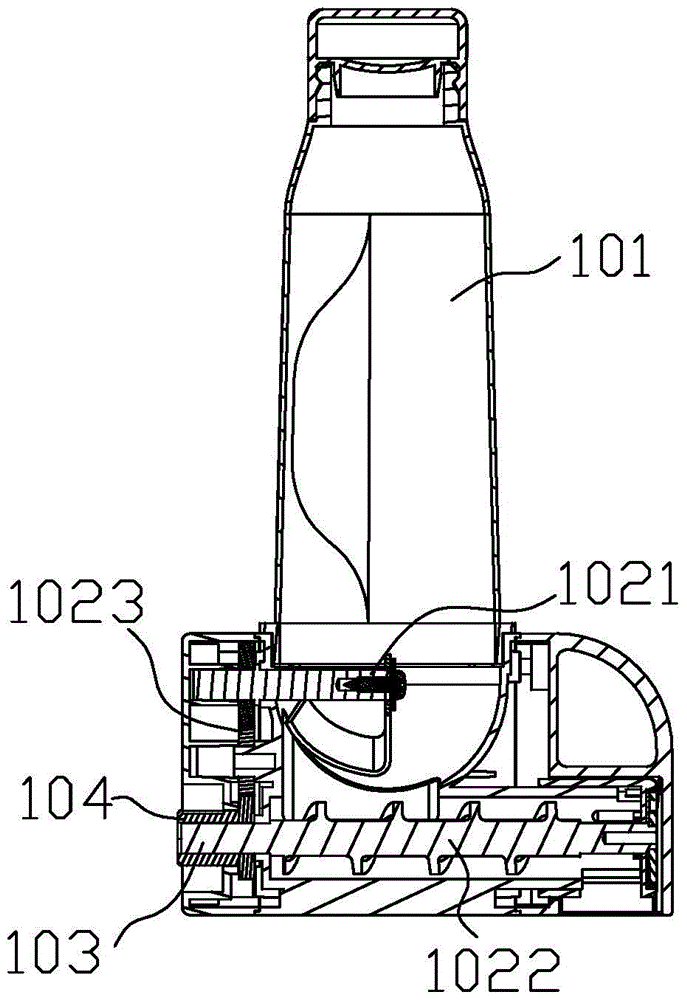

[0048] refer to figure 1 and figure 2, the cooking stocker of the present invention has a stocker body 100, and the stocker body 100 is provided with a cavity 101 for storing materials. The stocker body 100 is provided with a feeding device 102 composed of mechanical components for automatic discharging. The feeding device 102 does not contain electrical components and is a part that can be cleaned directly.

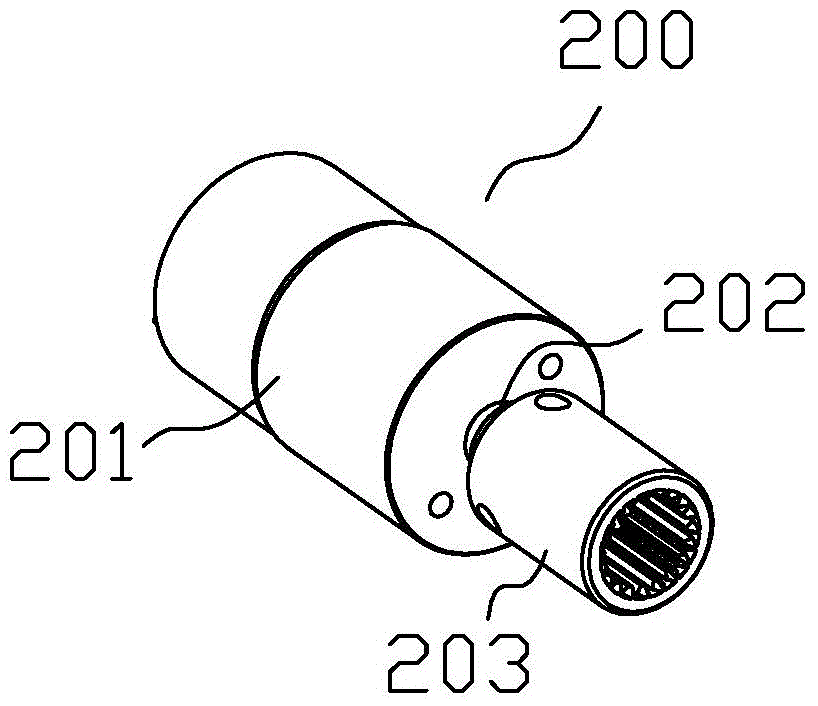

[0049] The feeding device 102 has a power input shaft 103 for inputting external power. The power input shaft 103 is used to drive the machine in the feeding device 102 to perform some work. The power input shaft 103 generally extends out of the stocker body 100 to facilitate docking with the drive mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com