escape pod thruster

A technology of pushing devices and escape cabins, which is applied in transportation and packaging, special-purpose vessels, underwater operation equipment, etc. It can solve the problems of inaccessibility of seawater, great safety hazards, and inability to float, etc., and achieves compact structure and high thrust load Large, safe and reliable working process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

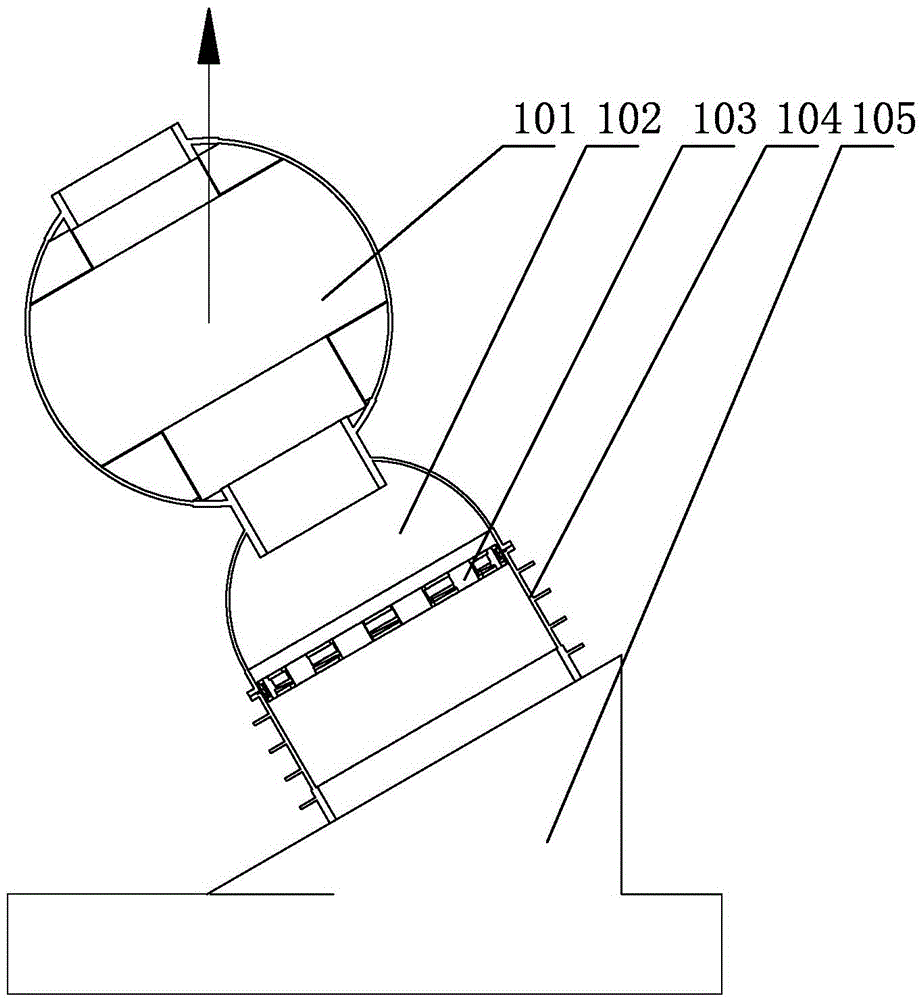

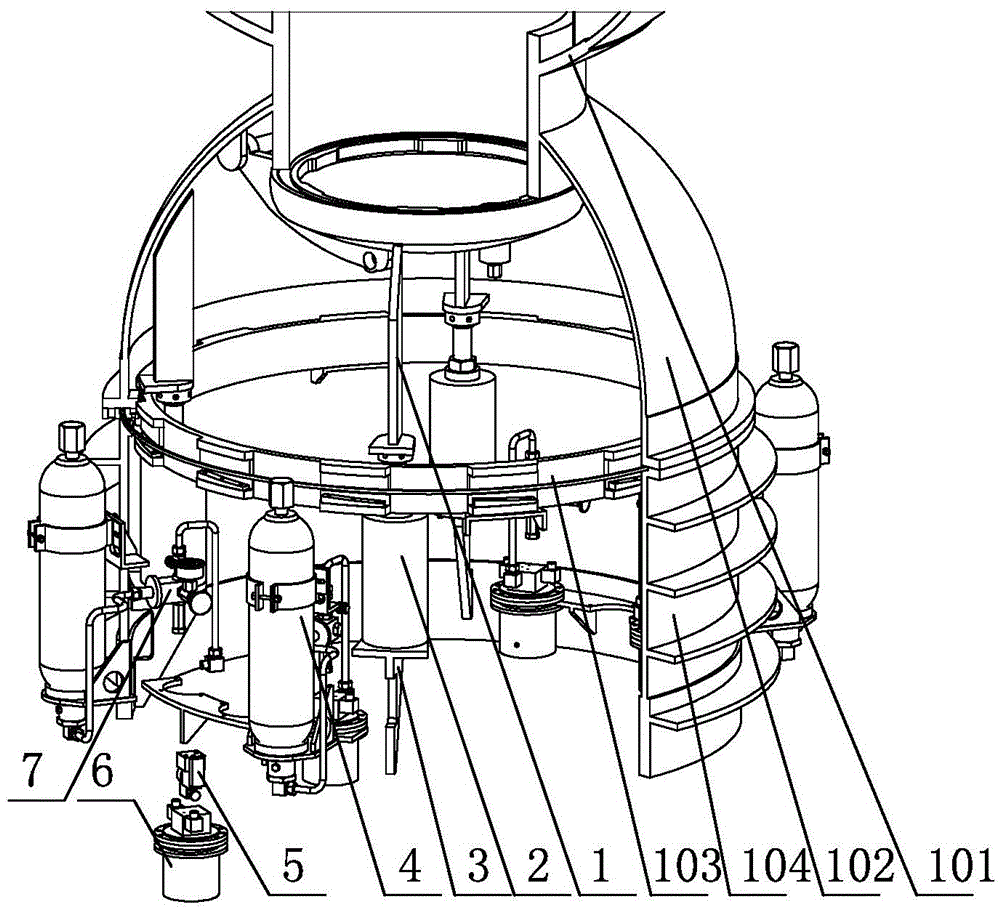

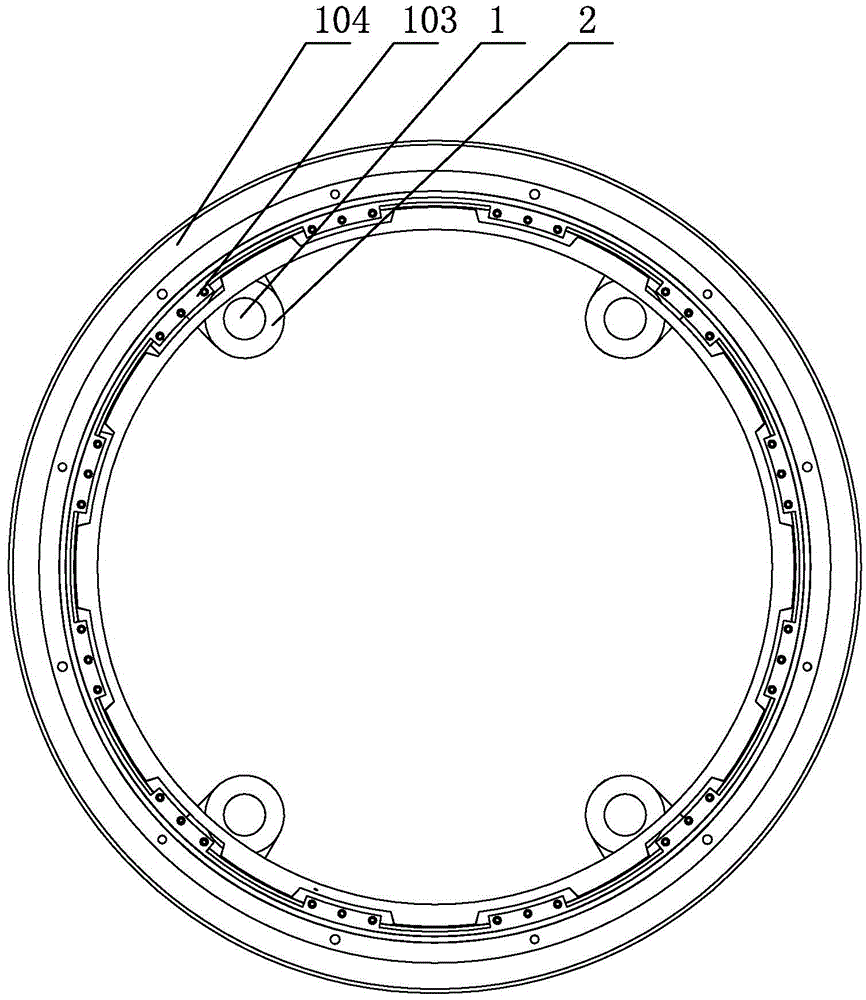

[0027] Such as figure 1 , figure 2 and image 3 As shown, the escape cabin jacking device of this embodiment includes a workstation docking fence 104 connected to a deep-sea workstation 105, an escape cabin docking fence 102 is installed on the top of the workstation docking fence 104 through a locking ring 103, and an escape cabin docking fence 102 is installed on the top of the escape cabin docking fence 102. The cabin 101 is located in the inner ring surface of the docking fence 104 of the workstation, and multiple groups of pushing devices are evenly installed. The structure of the pushing device is: including the mounting seat 3, the oil cylinder 2 is fixed on the mounting seat 3, and the piston rod head of the oil cylinder 2 A counter force support 1 is installed through the connector, and the top of the counter force support 1 ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com