Supplementary water barge launching construction method

A construction method and technology for replenishing water, which are applied in the directions of slipway, ship, transportation and packaging, etc., can solve problems such as controllability and control that cannot guarantee construction safety, it is difficult for the winch wire rope to not interfere, and the winch is not easy to set temporary construction power supply and other problems. , to achieve the effect of convenient and quick layout, reduce the difficulty of safety monitoring, and reduce labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

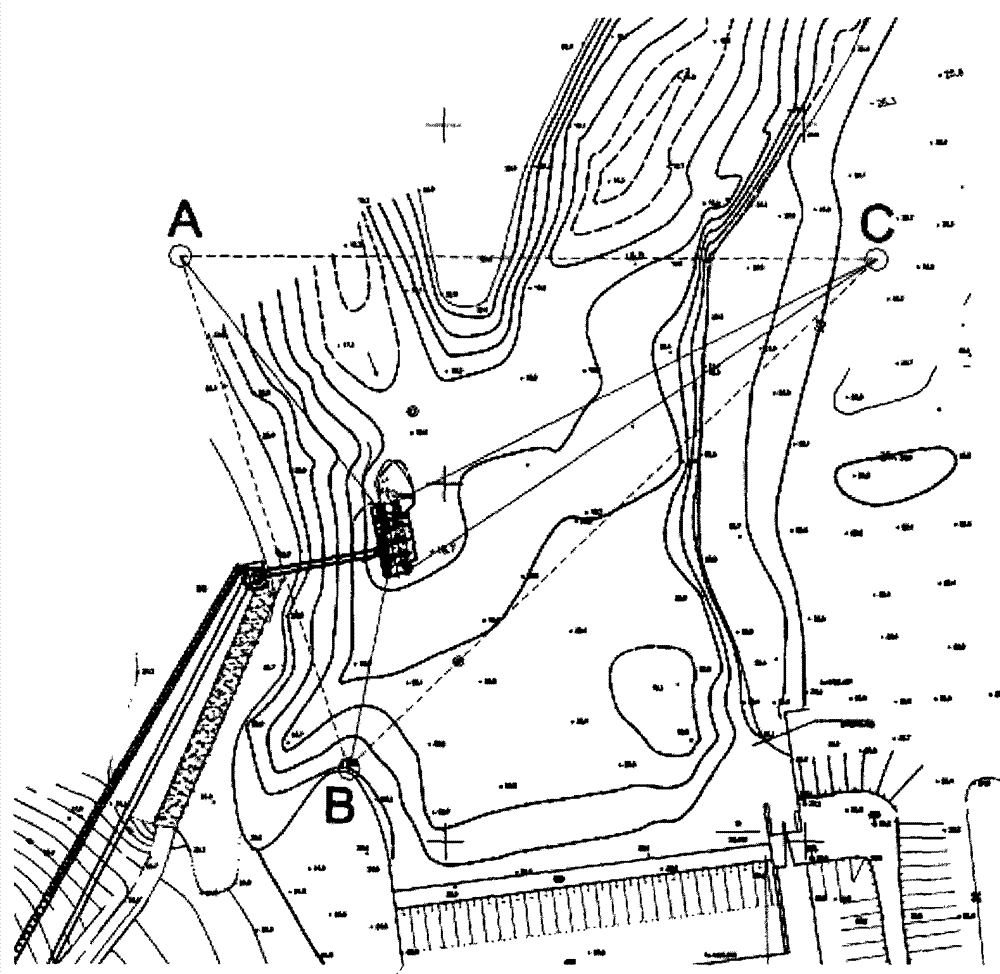

[0025] 1. Four winches are arranged at the four corners of the hull, the overall construction difficulty is reduced, and the placement is convenient, and the four corner winches on the ship are set to be semi-movable, which is convenient for direction adjustment during the barge shifting process.

[0026] 2. Only one steel wire rope guide ground anchor point will be constructed in the river bank construction. On the west bank of the river, two ground cattle are used as guiding ground anchor points, and on the east bank of the river, only a temporary concrete ground anchor is set.

[0027] 3. The two anchor chains at Diniu A and B are not launched with the ship. After throwing the two Hall anchors in the water, the hull moves to the shore to hoist the steel approach bridge for connection. After the hull moves to the predetermined position, use the winch on the ship to pull the shore anchor. The chain is in place.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com