Method for forming plates on basis of vibration by aid of flexible male die

A plate and punch technology, applied in the field of plate soft punch forming based on vibration, can solve the problems of complex forming equipment, numerous processing passes, and high investment costs, so as to suppress the occurrence and development of cracks, and promote fluidity and force transmission Performance, the effect of improving the forming limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

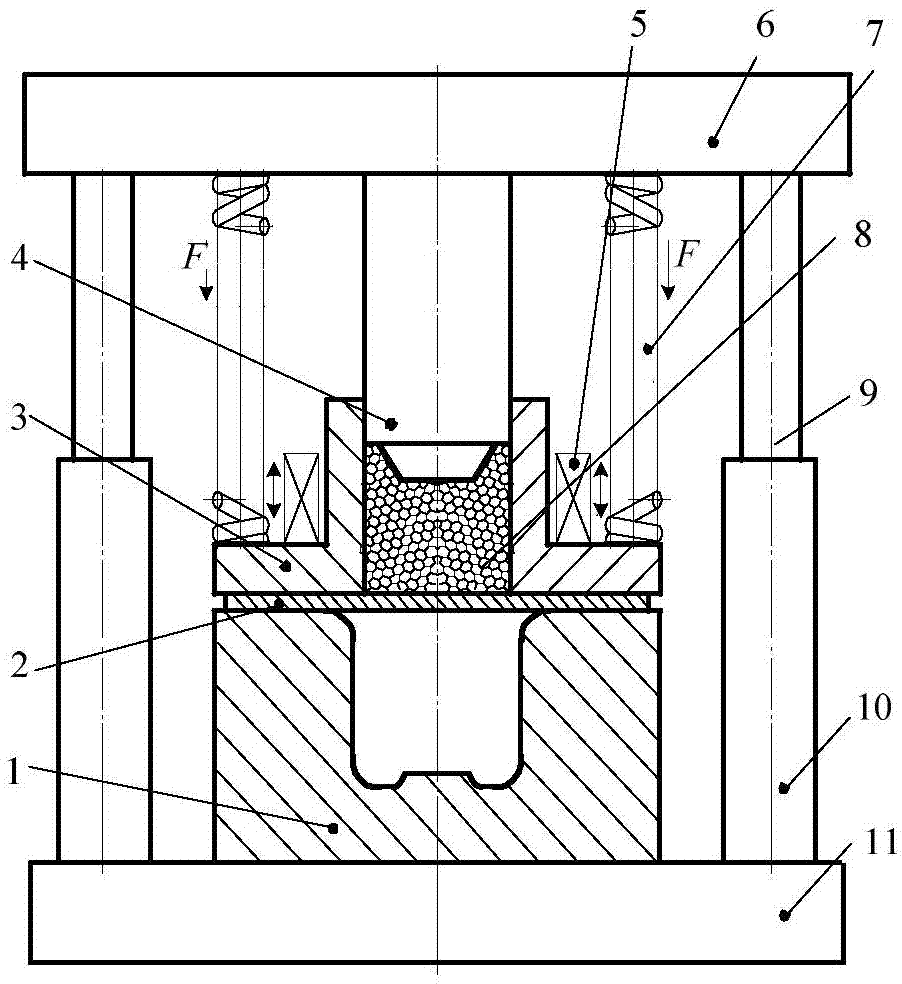

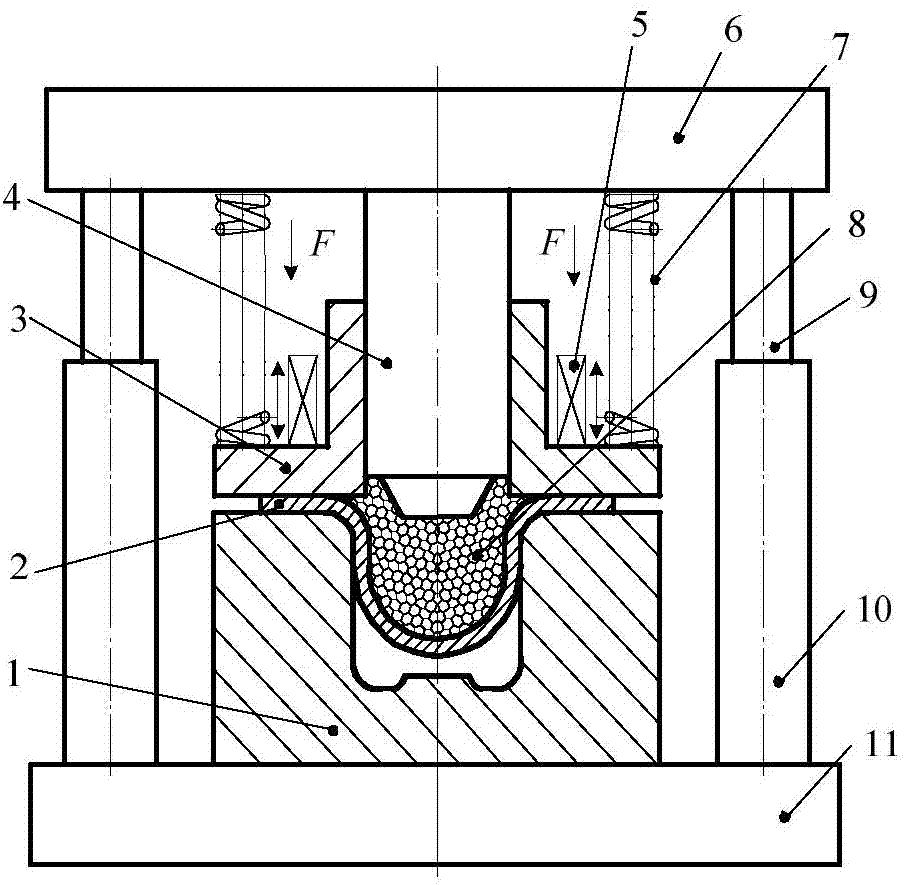

[0022] (1) Fix the upper and lower mold bases on the upper and lower worktables of the stamping machine respectively, and place the AA1020 aluminum sheet between the die and the blank holder;

[0023] (2) The blank-holding force applying device is composed of four springs, and the initial blank-holding force is applied to the sheet through the blank-holding ring, the metal sheet blank is pressed tightly, and the blank-holding ring and the metal sheet form a cylindrical shape as a barrel; by The blank-holding force applying device exerts the blank-holding force on the metal sheet through the blank-holding ring, which can suppress the wrinkling of the sheet in the flange area and ensure the smooth progress of deep drawing;

[0024] (3) Pour ceramic particles with a particle size of 0.125-0.25 mm into the feeding barrel, and the pouring height is 1.2 times the diameter of the barrel;

[0025] (4) The vibrating devices evenly installed on the blank holder ring, that is, four elect...

Embodiment 2

[0029] (1) Fix the upper and lower mold bases on the upper and lower worktables of the stamping machine respectively, and place the 304 stainless steel plate between the die and the blank holder;

[0030] (2) The blank-holding force applying device is composed of four hydraulic cylinders, which apply initial blank-holding force to the sheet through the blank-holding ring, the metal sheet blank is pressed tightly, and the blank-holding ring and the metal sheet form a cylindrical shape, as Barrel; the blank-holding force exerted by the blank-holding force applying device on the metal sheet through the blank-holding ring can suppress the wrinkling of the sheet in the flange area and ensure the smooth progress of deep drawing;

[0031] (3) Pour steel shot particles with a particle size of 0.2-0.3 mm into the feeding barrel, and the charging height is twice the diameter of the barrel;

[0032] (4) The vibrating devices evenly installed on the blank holder ring, that is, four pneuma...

Embodiment 3

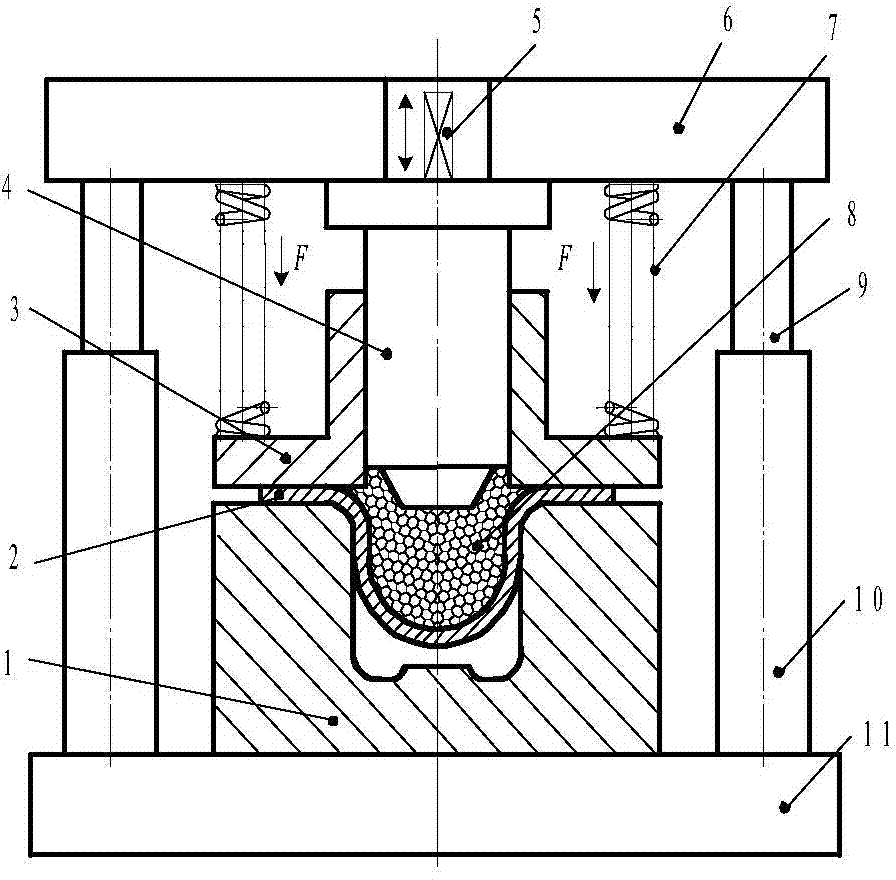

[0036] (1) Fix the upper and lower mold bases on the upper and lower worktables of the stamping machine respectively, and place the 6061 aluminum alloy plate between the die and the blank holder;

[0037] (2) The blank-holding force applying device is composed of four springs, and the initial blank-holding force is applied to the sheet through the blank-holding ring, the metal sheet blank is pressed tightly, and the blank-holding ring and the metal sheet form a cylindrical shape as a barrel; by The blank-holding force applying device exerts the blank-holding force on the metal sheet through the blank-holding ring, which can suppress the wrinkling of the sheet in the flange area and ensure the smooth progress of deep drawing;

[0038] (3) Pour SiO2 particles 8 with a particle size of 0.15-0.20 mm into the feeding barrel, and the pouring height is 1.5 times the diameter of the barrel;

[0039] (4) The ultrasonic vibrator installed on the top of the indenter starts to excite the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com