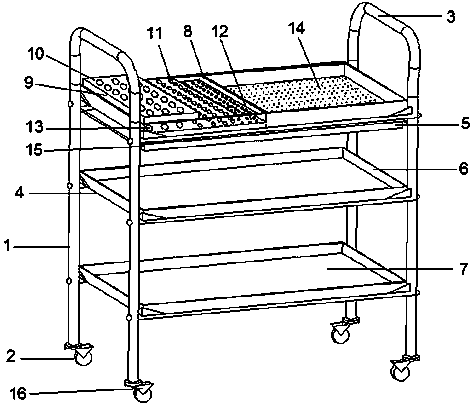

Chemical instrument trolley

A chemical instrument and stage technology, applied in the field of chemical instrument carts, can solve the problems of test tube breakage, low stage, collision, etc., and achieve the effect of being difficult to move.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described below in conjunction with accompanying drawing.

[0018] refer to figure 1 As shown, a chemical instrument cart includes a frame body 1 and a pulley 2, the frame body 1 is fixedly connected with the pulley 2, and the frame body 1 includes a handrail 3, a stage 4 and a stretching water receiving basin 5 , the loading table 4 is provided with more than two layers, the surrounding board 6 is arranged around the loading table 4, the table top 7 of the loading table 4 is a corrosion-resistant non-slip table top, and the loading table 4 on the top A clapboard 8 is arranged on it, and a detachable test tube rack 9 is arranged on one side of the clapboard 8, and the detachable test tube rack 9 is set in steps, the detachable test tube rack 9 is divided into three layers, and the detachable test tube rack 9 is divided into three layers. Type test tube rack frame surface 10 is provided with test tube round holes 11, and described test tube roun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com