Desulfurization beneficiating device and refitting method thereof applied to existing equipment

A technology of existing equipment and spray pipes, applied in the field of desulfurization synergistic devices, can solve the problems of increasing the impurity content in gypsum, reducing the purity of gypsum, and affecting the stable operation of the desulfurization system, so as to increase the coverage area, improve desulfurization efficiency, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] In order to more clearly illustrate the technical solutions in the embodiments of the present invention or the prior art, the following will briefly introduce the drawings that need to be used in the description of the embodiments or the prior art. Obviously, the accompanying drawings in the following description are only These are some embodiments of the present invention. Those skilled in the art can also obtain other drawings based on these drawings without creative work.

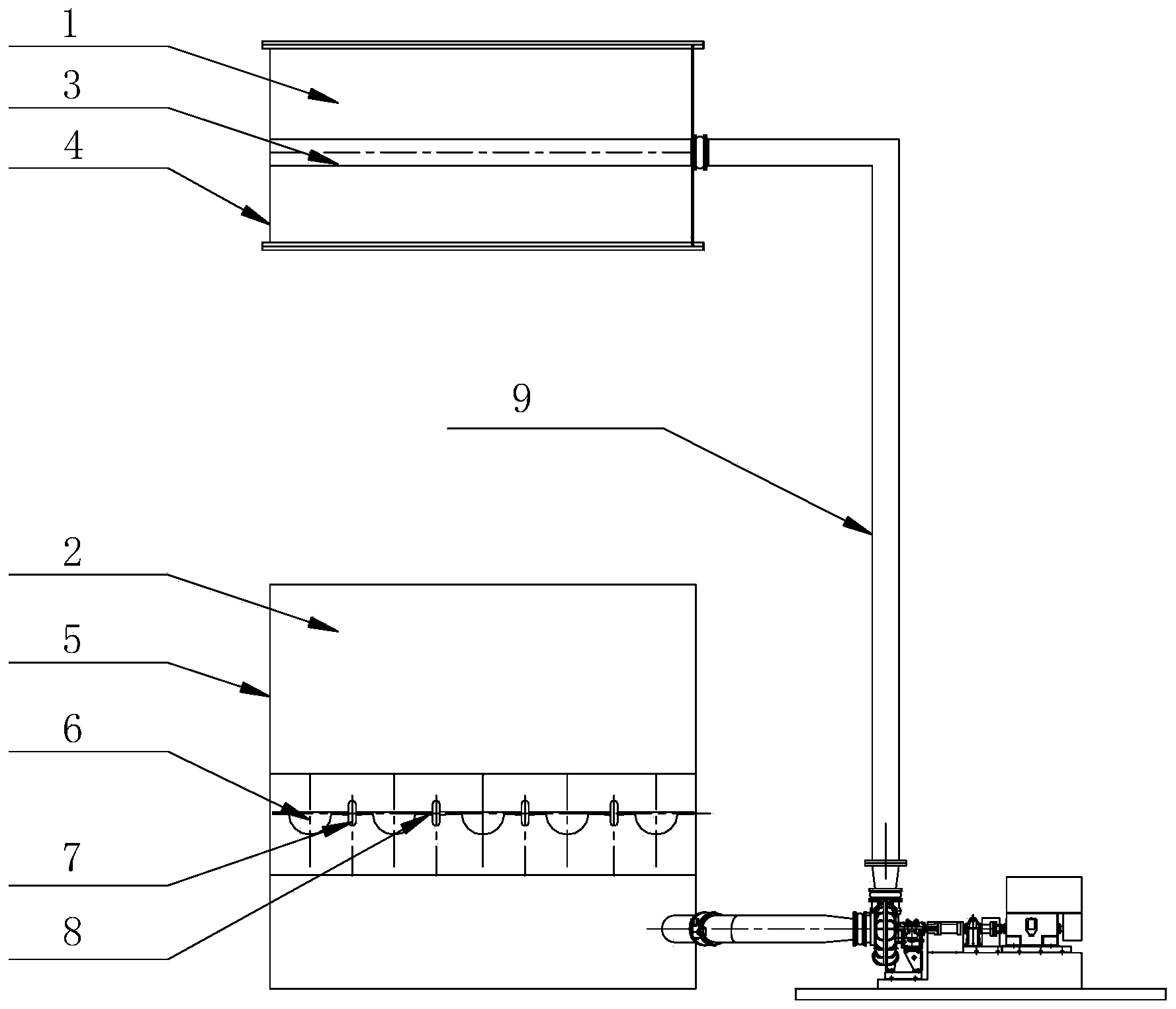

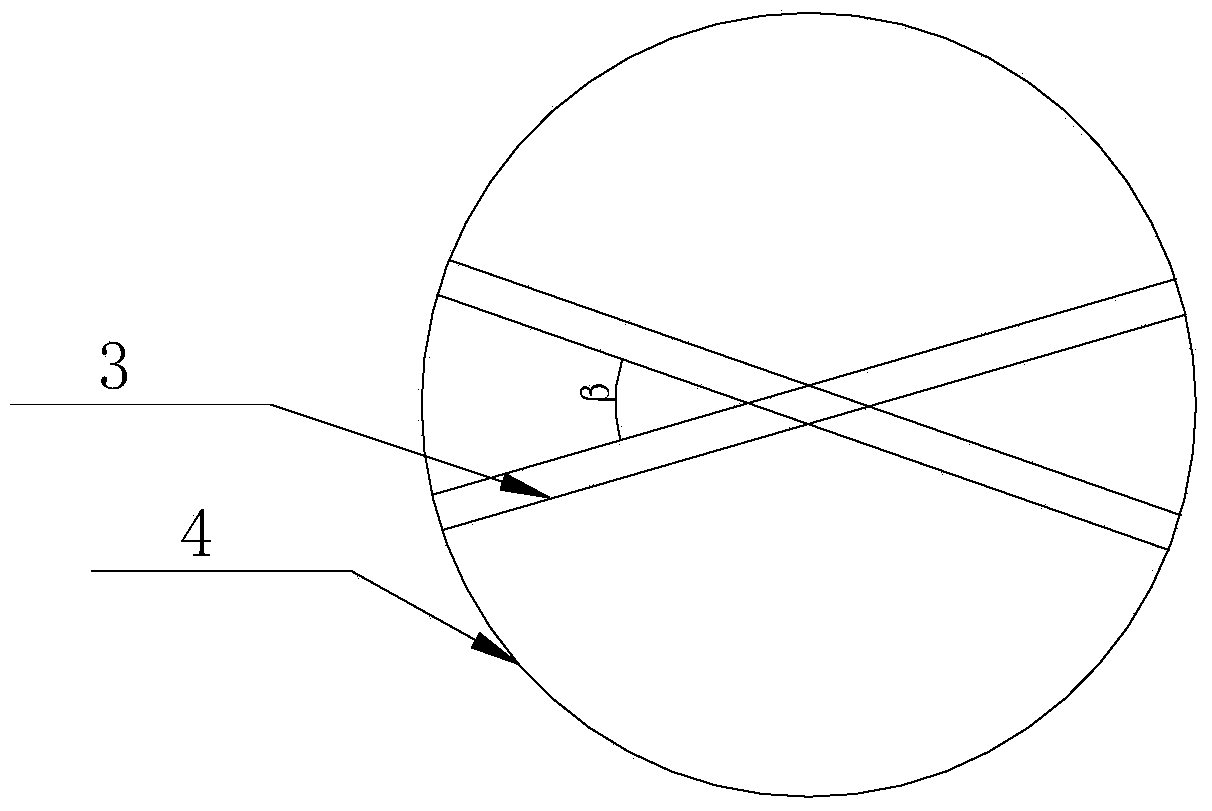

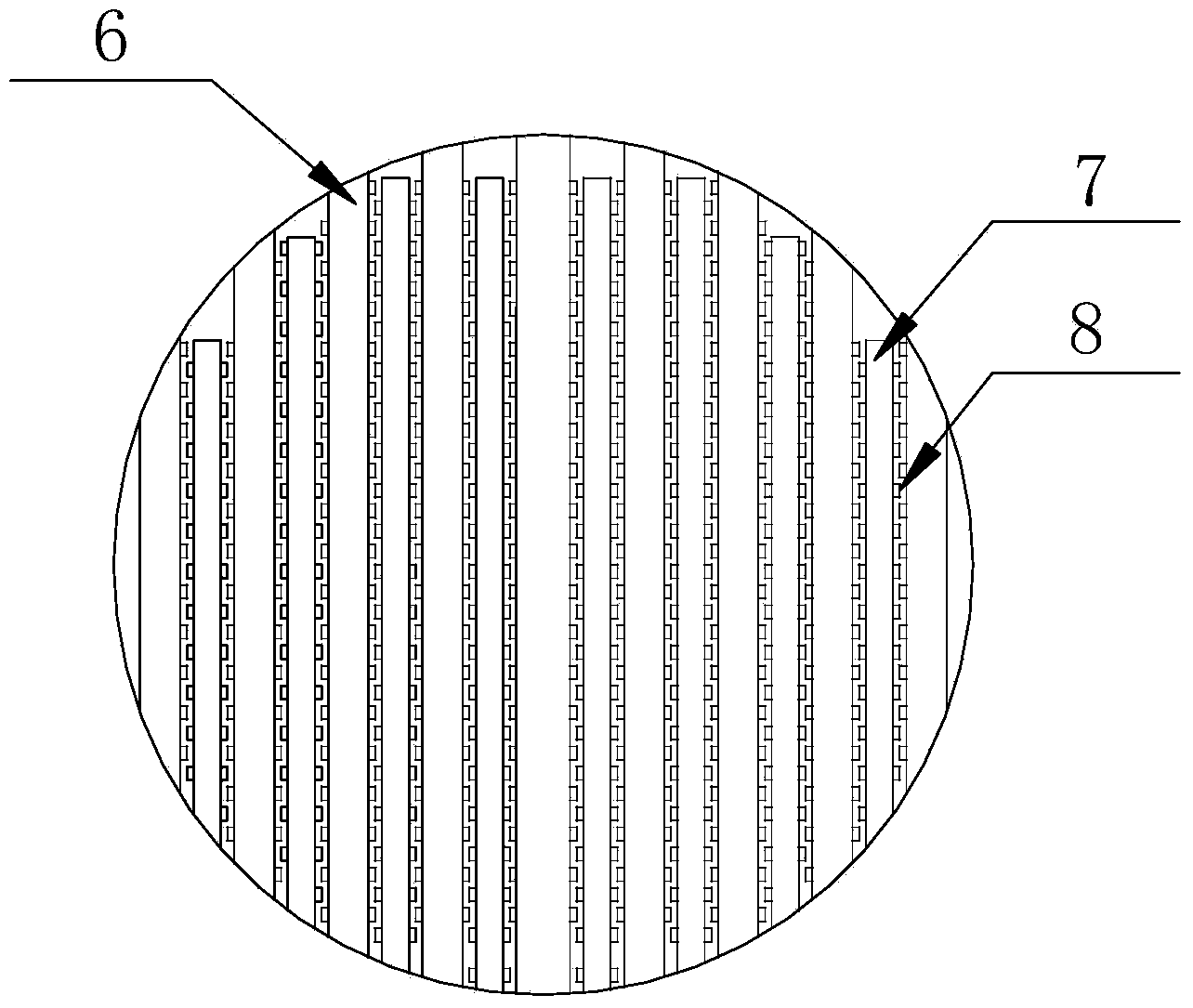

[0065] In one embodiment of the present invention, referring to the attached figure 1 , the desulfurization synergistic device includes a slurry spray module 1 and a slurry tank capacity expansion partition module 2, wherein the slurry spray module 1 is provided with a spray pipe 3 inside, and the slurry tank capacity expansion partition module 2 is provided with at least one Partition isolation components for partitioning the slurry tank into an oxidation zone and an absorption zone. The slurry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com