Automatic filter with rotational flow device

A swirl device and filter technology, which is applied in the field of water treatment equipment, can solve the problems of difficult mechanical cleaning, decreased filtering effect, and clogging of stainless steel filter nets, and achieve the effects of reducing operation and maintenance costs, reducing clogging, and improving impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

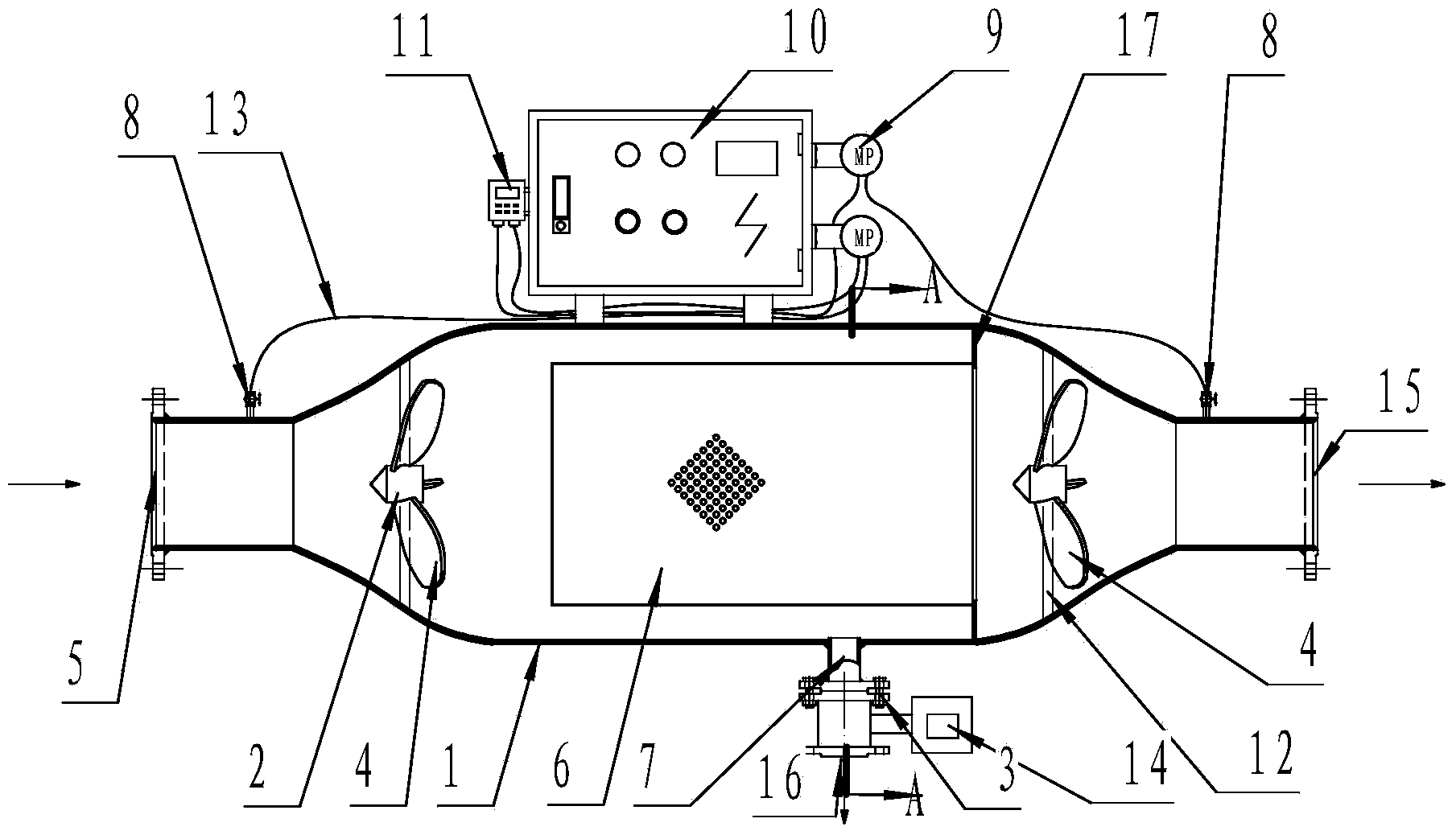

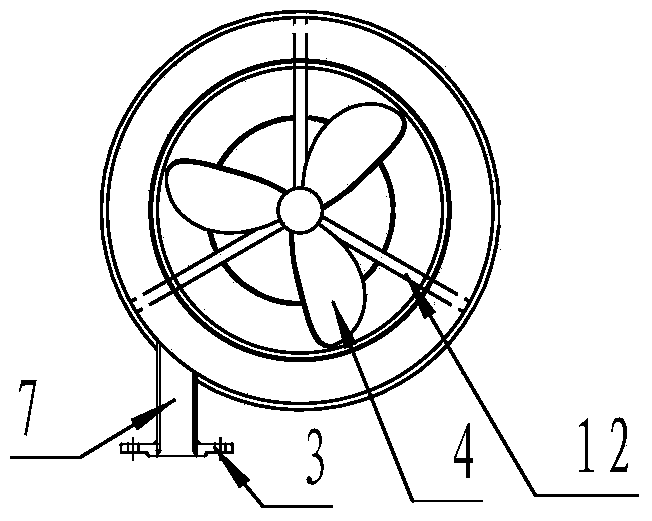

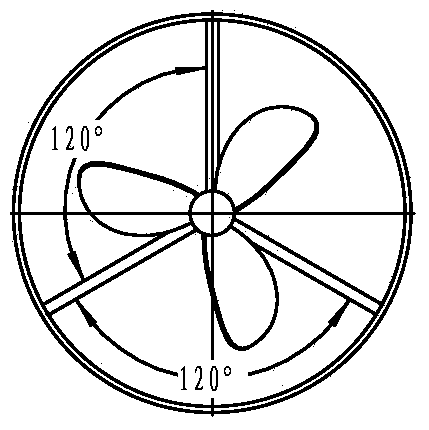

[0019] Embodiment 1, a kind of automatic filter with cyclone device, comprises cylinder body 1 made of carbon steel or stainless steel, water inlet 5, water outlet 15, filter screen 6 made of stainless steel, sewage pipe 7, is characterized in that: The two ends of the horizontally installed cylinder body are respectively installed with a water inlet and a water outlet through a tapered transition zone, and the filter screen is installed in the cylinder body by a filter screen fixing plate 17, and the tapered transition zones at both ends of the cylinder body are respectively equipped with three uniform The water inlet deflector and the water outlet deflector composed of distributed blades, the deflector 4 is fixed in the tapered transition zone by the support frame 12 .

Embodiment 2

[0020] Embodiment 2, a kind of automatic filter with swirl device, comprises cylinder body 1 made of carbon steel or stainless steel, water inlet 5, water outlet 15, filter screen 6 made of stainless steel, sewage pipe 7, is characterized in that: The two ends of the horizontally installed cylinder body are respectively installed with a water inlet and a water outlet through a tapered transition zone, and the filter screen is installed in the cylinder body by a filter screen fixing plate 17, and the tapered transition zones at both ends of the cylinder body are respectively equipped with three uniform The water inlet deflector and the water outlet deflector composed of distributed blades, the deflector 4 is fixed in the tapered transition zone by the support frame 12 . The sewage pipe is installed in the tangential direction of the outer circumference of the cylinder, and the outlet end of the sewage pipe is connected to the sewage valve 14 through the flange 3 .

[0021] The ...

Embodiment 3

[0022] Embodiment 3, a kind of automatic filter with cyclone device, comprises cylinder body 1 made of carbon steel or stainless steel, water inlet 5, water outlet 15, filter screen 6 made of stainless steel, sewage pipe 7, is characterized in that: The two ends of the horizontally installed cylinder body are respectively installed with a water inlet and a water outlet through a tapered transition zone, and the filter screen is installed in the cylinder body by a filter screen fixing plate 17, and the tapered transition zones at both ends of the cylinder body are respectively equipped with three uniform The water inlet deflector and the water outlet deflector composed of distributed blades, the deflector 4 is fixed in the tapered transition zone by the support frame 12 . The sewage pipe is installed in the tangential direction of the outer circumference of the cylinder, and the outlet end of the sewage pipe is connected to the sewage valve 14 through the flange 3 .

[0023] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com