Novel tobacco product production method

A tobacco product and a new type of technology, applied in tobacco, tobacco preparation, application, etc., can solve the problems of large differences in cigarettes, large differences in the actual experience of electronic cigarettes, and the inability to truly simulate the flavor of cigarettes, so as to facilitate the volatilization of flavors, improve utilization rates, The effect of enriching sensory stimulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A method for preparing a novel tobacco product is provided, comprising the steps of:

[0043] S1. Preparation of reconstituted tobacco leaf paper base: the reconstituted tobacco leaf paper base is prepared by a papermaking method, and the tobacco stem residue and / or tobacco powder residue after impregnation treatment is refined, sheeted, pressed and dried to obtain a reconstituted tobacco leaf paper base;

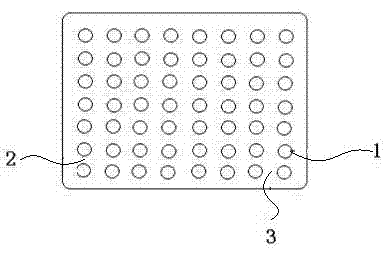

[0044] S2. Punch holes on the reconstituted tobacco leaf paper base prepared in S1. The hole diameter of the holes is 0.4 mm, the hole spacing is 1 mm, and the hole spacing is 1.5 mm.

[0045] S3. prepare coating solution;

[0046] S4. Coating the coating solution prepared in S3 on the perforated reconstituted tobacco leaf paper base in S2, the coating amount is 5-15%, drying, and rolling into the tobacco product according to the required size.

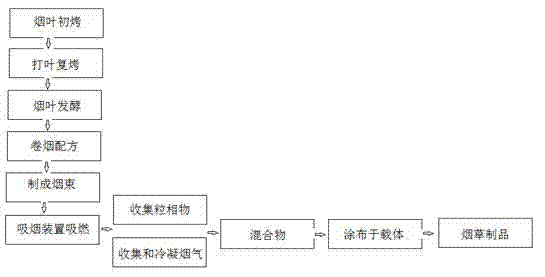

[0047] The schematic diagram of the preparation process of the coating solution is shown in the attached figure 2 shown...

Embodiment 2

[0061] A method for preparing a novel tobacco product is provided, comprising the steps of:

[0062] S1. Preparation of reconstituted tobacco leaf paper base: the reconstituted tobacco leaf paper base is prepared by a papermaking method, and the tobacco stem residue and / or tobacco powder residue after impregnation treatment is refined, sheeted, pressed and dried to obtain a reconstituted tobacco leaf paper base;

[0063] S2. Punch holes on the reconstituted tobacco leaf paper base prepared in S1. The hole diameter of the holes is 0.6mm, the hole spacing is 1.5mm, and the hole spacing is 2mm.

[0064] S3. Prepare coating solution:

[0065] S4. Coating the coating solution prepared in step S3. on the perforated reconstituted tobacco leaf paper base in S2., the coating amount is 5-15%, drying, and rolling into the tobacco product according to the required size.

[0066] The preparation of coating solution is carried out as follows:

[0067] S31. 2012 Guizhou Zhongjusan (C1) re-...

Embodiment 3

[0076] A method for preparing a novel tobacco product is provided, comprising the steps of:

[0077] S1. Preparation of reconstituted tobacco leaf paper base: the reconstituted tobacco leaf paper base is prepared by a papermaking method, and the tobacco stem residue and / or tobacco powder residue after impregnation treatment is refined, sheeted, pressed and dried to obtain a reconstituted tobacco leaf paper base;

[0078] S2. Punch holes on the reconstituted tobacco leaf paper base prepared in S1. The hole diameter of the holes is 0.8 mm, the hole spacing is 3 mm, and the hole spacing is 2 mm.

[0079] S3. prepare coating solution;

[0080] S4. Coating the coating solution prepared in step S3. on the perforated reconstituted tobacco leaf paper base in S2., the coating amount is 5-15%, drying, and rolling into the tobacco product according to the required size.

[0081] The preparation of coating solution is carried out as follows:

[0082] S31.2012 Yunnan Zhongjusan (A) re-cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com