Chuck for a machine tool for machining a tubular, rotating workpiece

A chuck and workpiece technology, applied in metal processing, tool holder accessories, metal processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

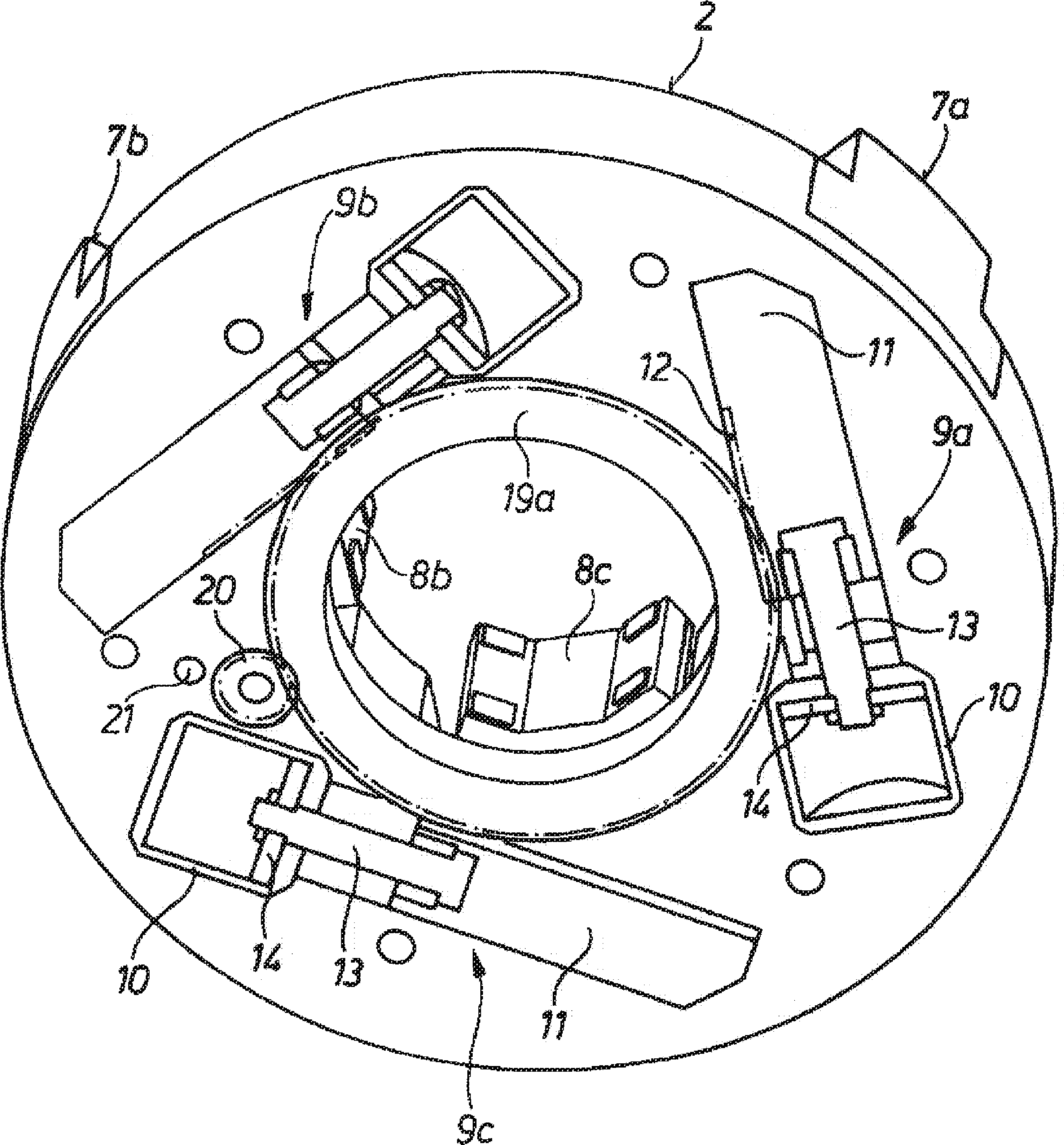

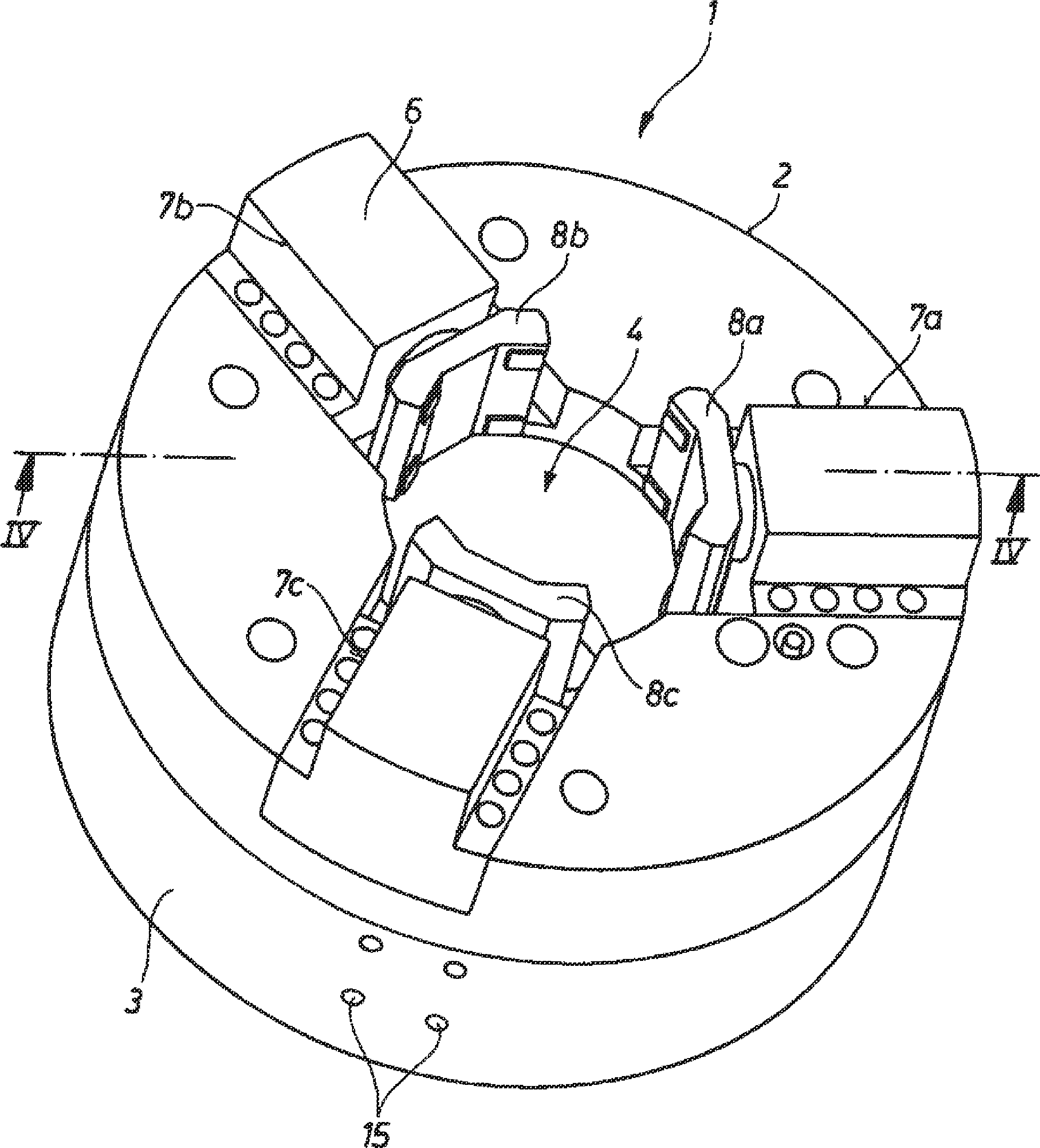

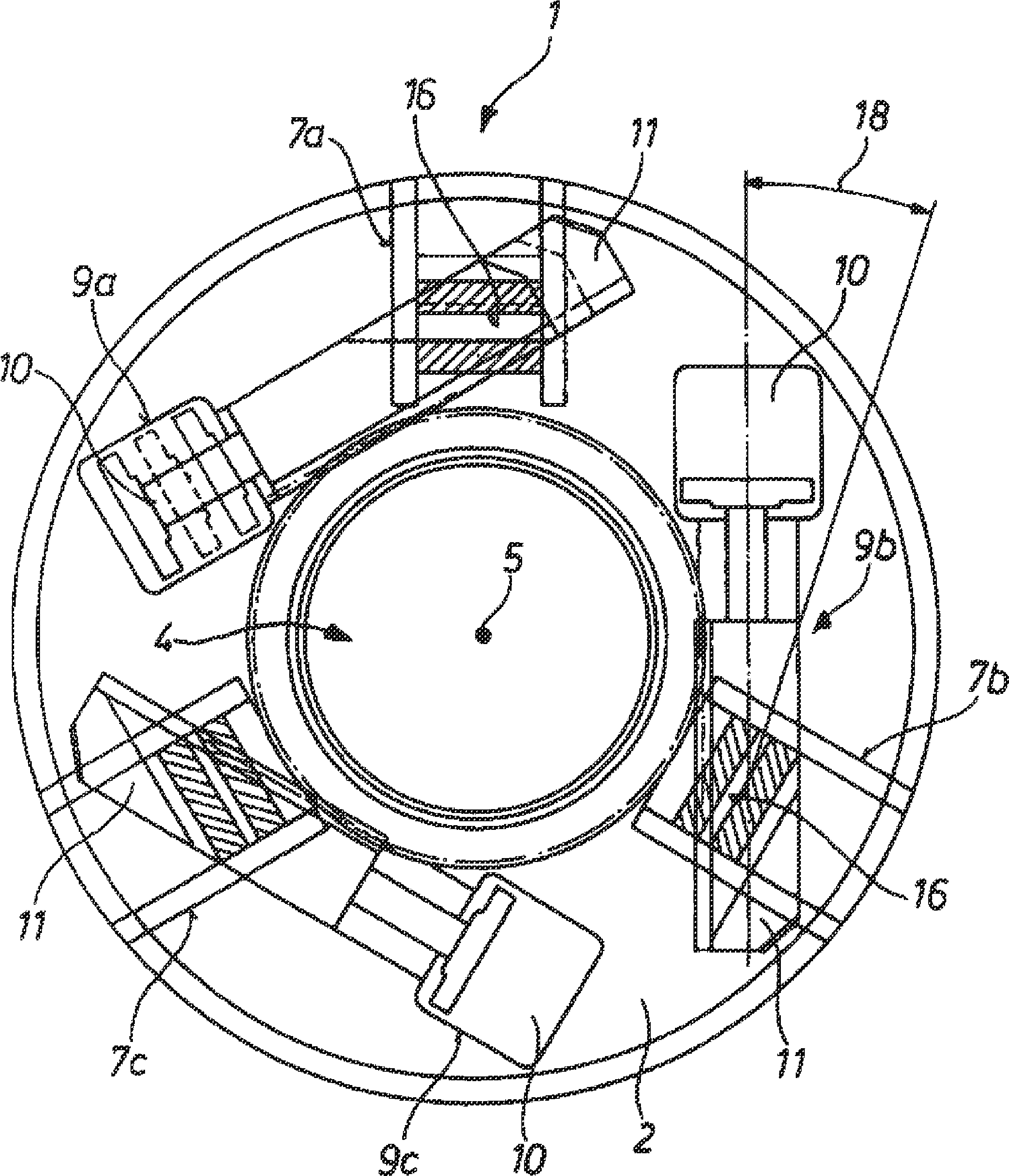

[0016] Machine tools for cutting threads or threaded joints at the ends of pipe fittings figure 1 The chuck 1 shown in includes a top plate 2 and a rearwardly coupled housing ring (Gehöusering). In order to accommodate the pipe to be machined (not shown), the chuck 1 has a central through hole 4, the center 5 of which coincides with the axis of rotation of the pipe rotating in the chuck. Arranged on the end face of the top plate 2 , evenly distributed over the circumference, are radially adjustable valves with respective clamping jaws 8 a , 8 b , 8 c , which are covered by a cover 6 , with respect to the center or axis of rotation 5 . Three clamping slides 7a, 7b, 7c, jaws 8a, 8b, 8c relative to the center or axis of rotation 5 (see image 3 ) to grip the fitting centrally.

[0017] In order to adjust the clamping slides 7a, 7b, 7c with the jaws 8a, 8b, 8c in the direction towards the center or the axis of rotation 5 of the chuck 1, for each clamping slide 7a, 7b, 7c a tange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com