LED with high luminous efficiency and high color rendering

A technology with high color rendering and high light efficiency, applied in electrical components, electric solid-state devices, circuits, etc., can solve problems affecting product promotion, poor color reproduction, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

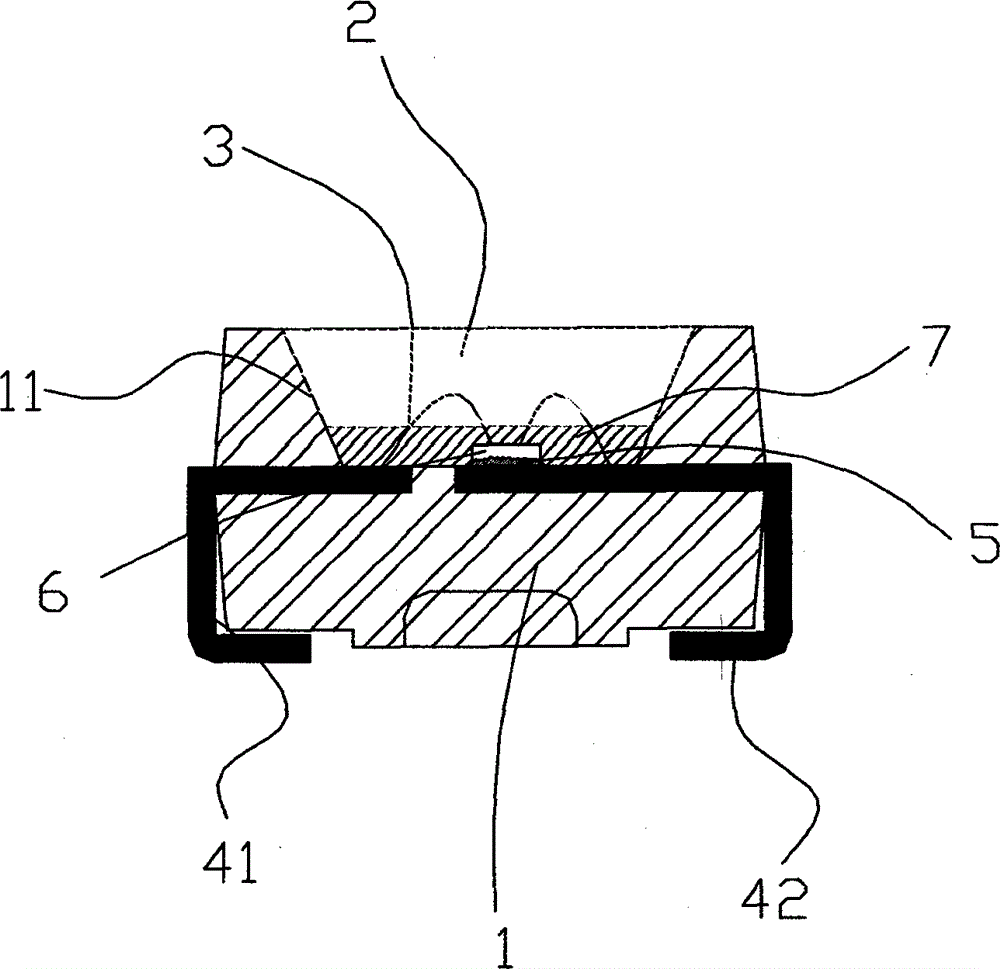

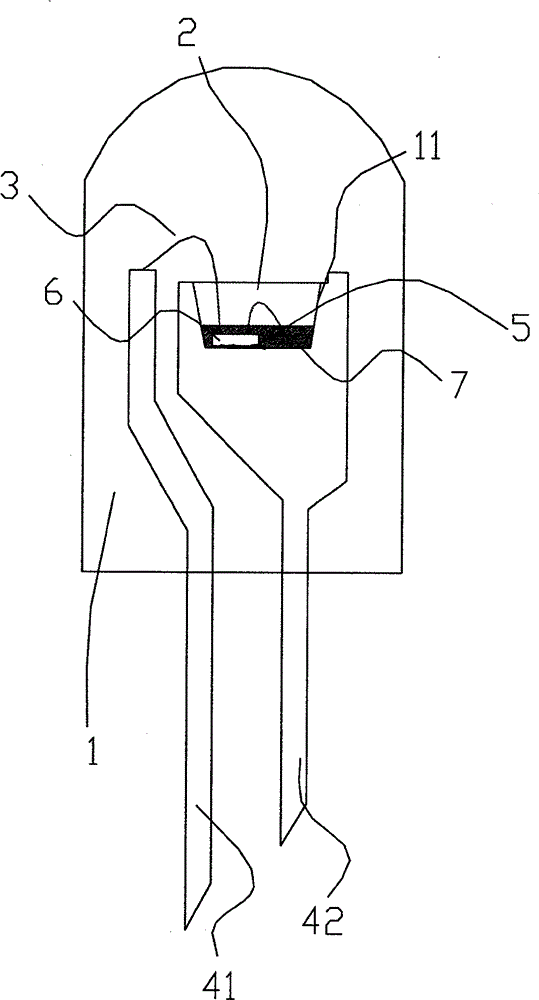

[0016] see figure 1 , figure 2 As shown, a LED with high light efficiency and high color rendering of the present invention includes a bracket cup 1, an inner concave cavity 11 is arranged on the bracket 1, and pins 41 and 42 are located on the corresponding two sides of the bracket 1, and the chip 6 passes through The crystal-bonding glue 5 is fixed inside the inner cavity 11 of the bracket. The bracket bowl 1 is an inner concave cavity 11 or a flat circuit board with a dam, phosphor powder and encapsulation glue are dotted in the bracket bowl, and baked to shape. For the packaged LED chip, the upper part of the chip is covered with the packaged glue yellow phosphor powder mixture 2 and the glue red phosphor powder mixture 7, and the above glue phosphor powder mixture is packaged twice.

[0017] Wherein, the LED chip is fixed on the bottom of the recessed cavity 11 through the crystal-bonding glue 5, and the upper part of the LED chip 6 is covered with the first layer of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com