Modeling method of medium-temperature coal tar total-fraction hydrogen cracking lumping kinetic model

A hydrocracking and mechanical model technology, applied in the field of coal tar, can solve the problems of unclear research objects, difficult division methods, and small scope of application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

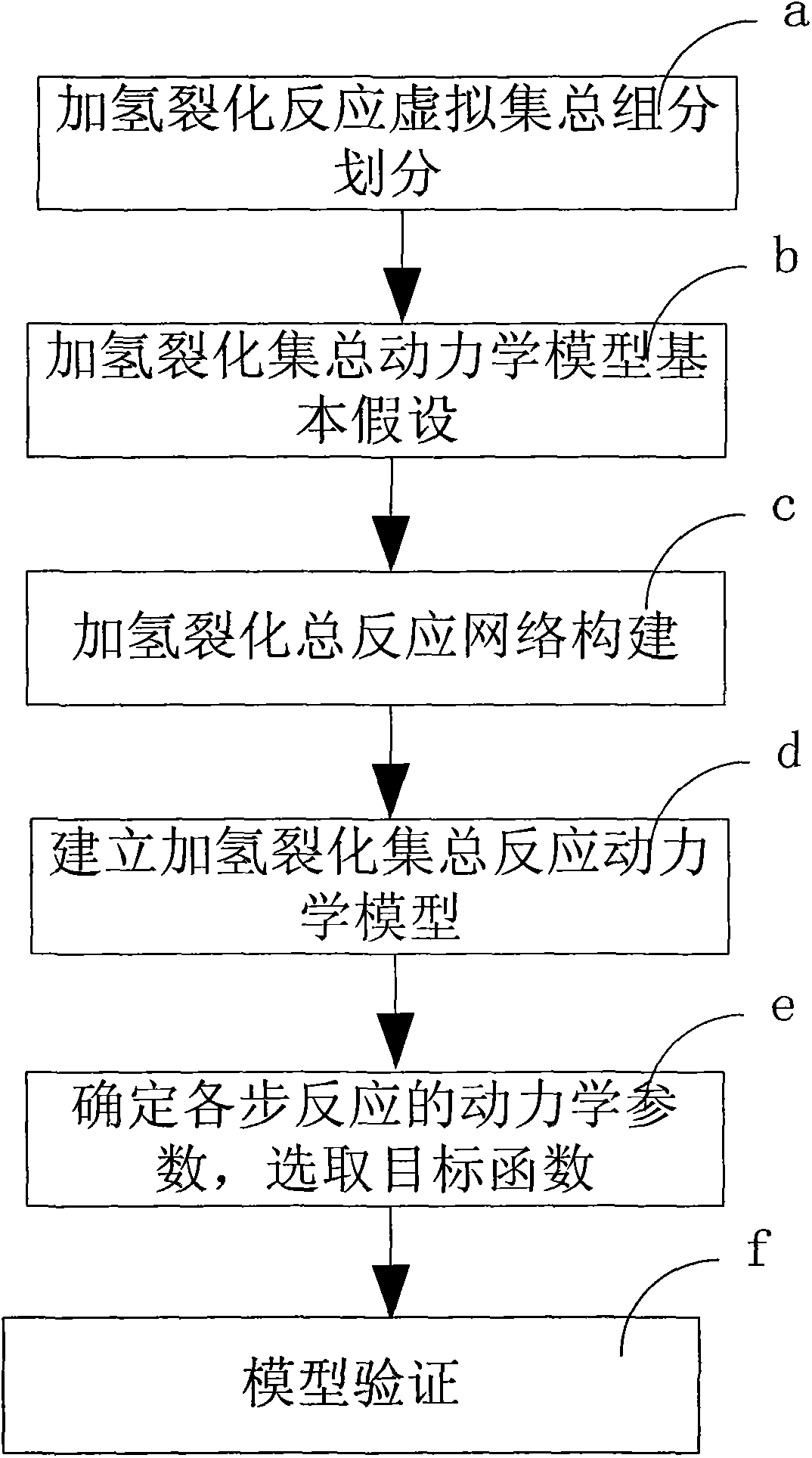

[0043] see figure 1 As shown, it is a flow chart of the modeling method for the lumped kinetic model of the full-fraction hydrocracking of medium-temperature coal tar in the present invention; the specific process of the modeling method for the lumped kinetic model of the full-fraction hydrocracking of medium-temperature coal tar in the present invention is:

[0044] Step a, dividing the virtual lumped components of the hydrocracking reaction;

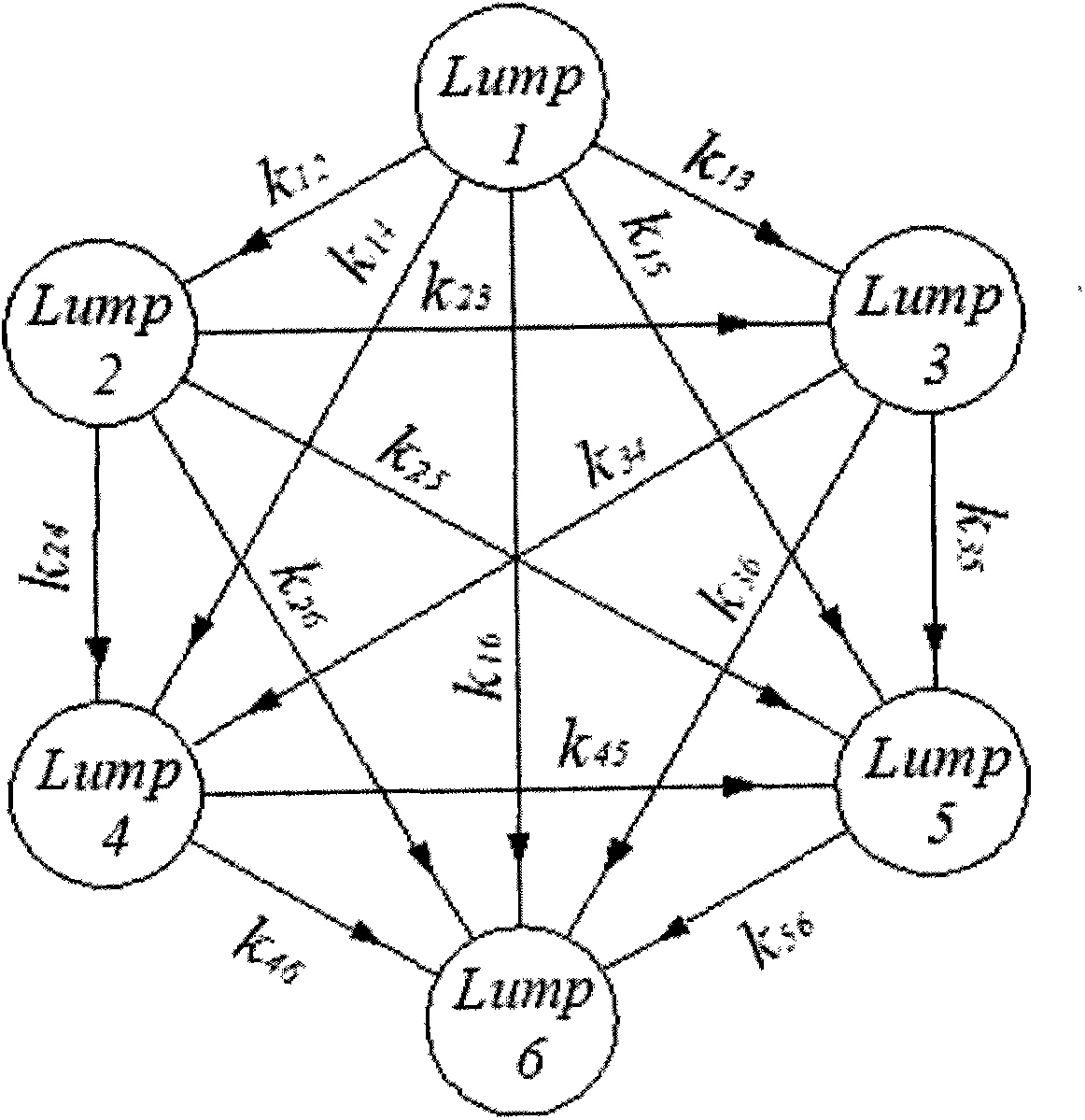

[0045] In the present invention, the hydrocracking reaction network is divided into raw oil and produced oil; the raw material oil is divided by the composition of coal tar group; the produced oil is divided by the fractions of commercial oil.

[0046] Colloids and asphaltenes in medium-temperature coal tar are heavy components that are difficult to process, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com