Capacitive touch screen structure suitable for two-layer cabling

A capacitive touch screen, double-layer technology, used in electrical digital data processing, input/output process of data processing, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the technical problems solved by the present invention, the technical solutions adopted, and the technical effects obtained easy to understand, the specific implementation manners of the present invention will be further described below in conjunction with the specific drawings.

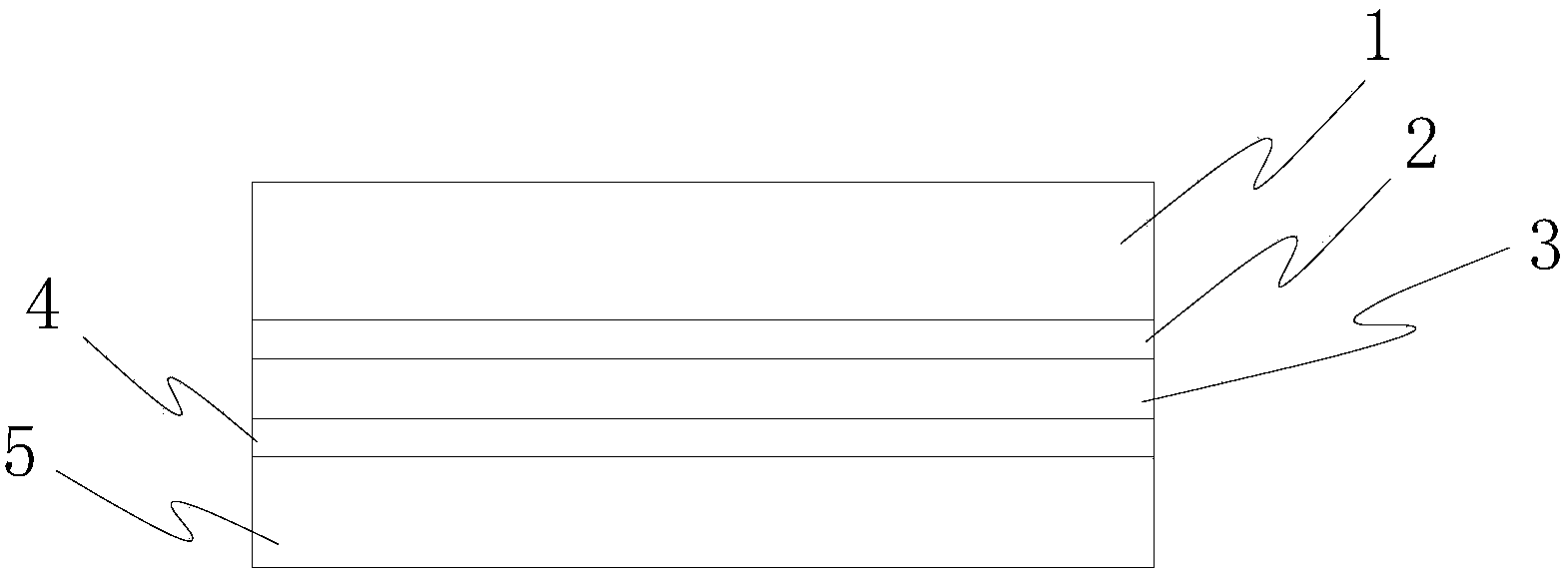

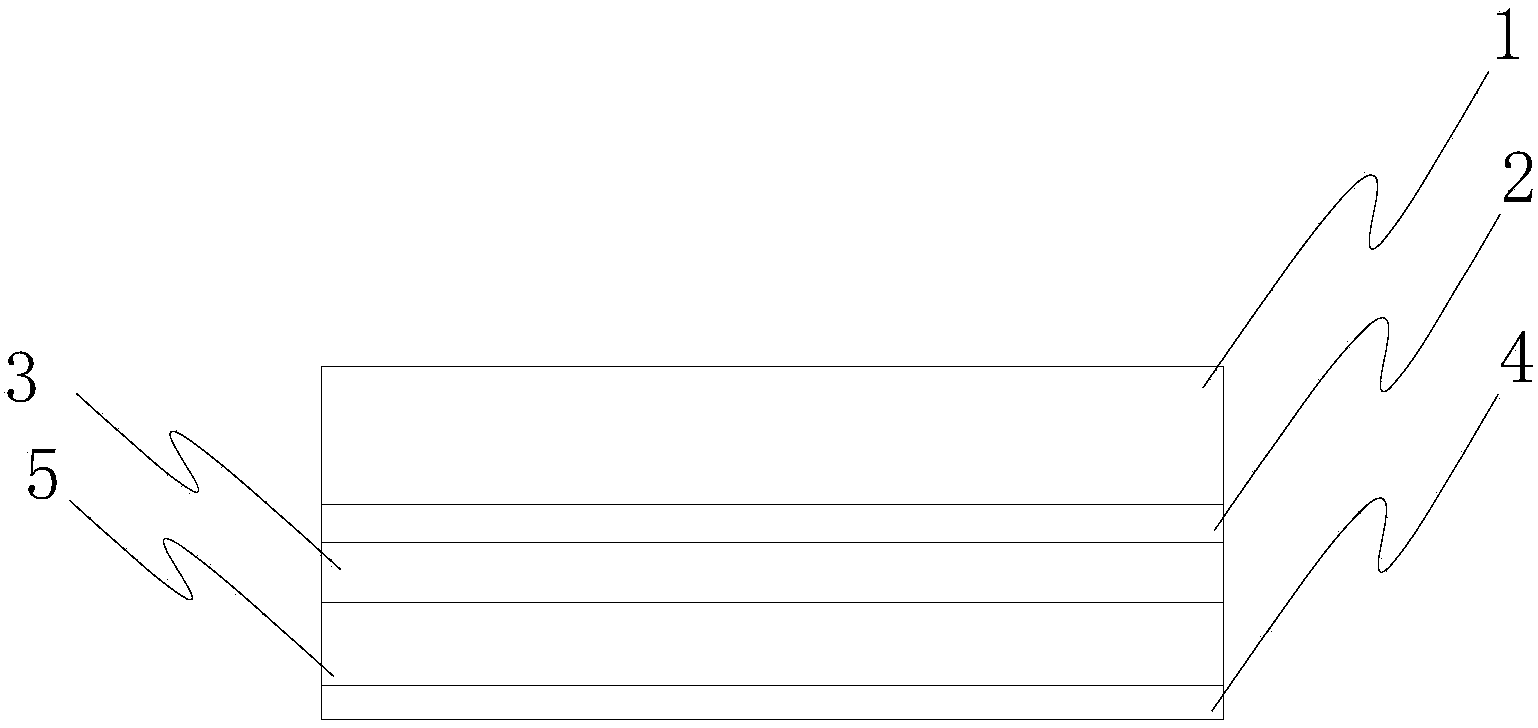

[0012] The invention discloses a capacitive touch screen structure suitable for double-layer wiring, which includes a glass layer (G) 1 located above and a film layer 5 (Film, referred to as F) located below, and the lower surface of the glass layer 1 is provided with The first ITO layer 2 makes the glass layer 1 act as a glass cover and realize the touch function. A second ITO layer 4 is provided on the film layer 5 , and the first ITO layer 2 and the film layer 5 are bonded together by an optically transparent adhesive (OCA) 3 .

[0013] The materials of the thin film layer 5, the ITO layer, the optically transparent adhesive and the related manufacturing techniques in the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com