Low-speed impact locating method for composite material cell structure

A grid structure, low-velocity impact technology, applied in positioning, instruments, measuring devices, etc., can solve the problems that the grid structure skin damage cannot be detected, the AGS skin damage cannot be detected, and it is difficult to be widely used.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

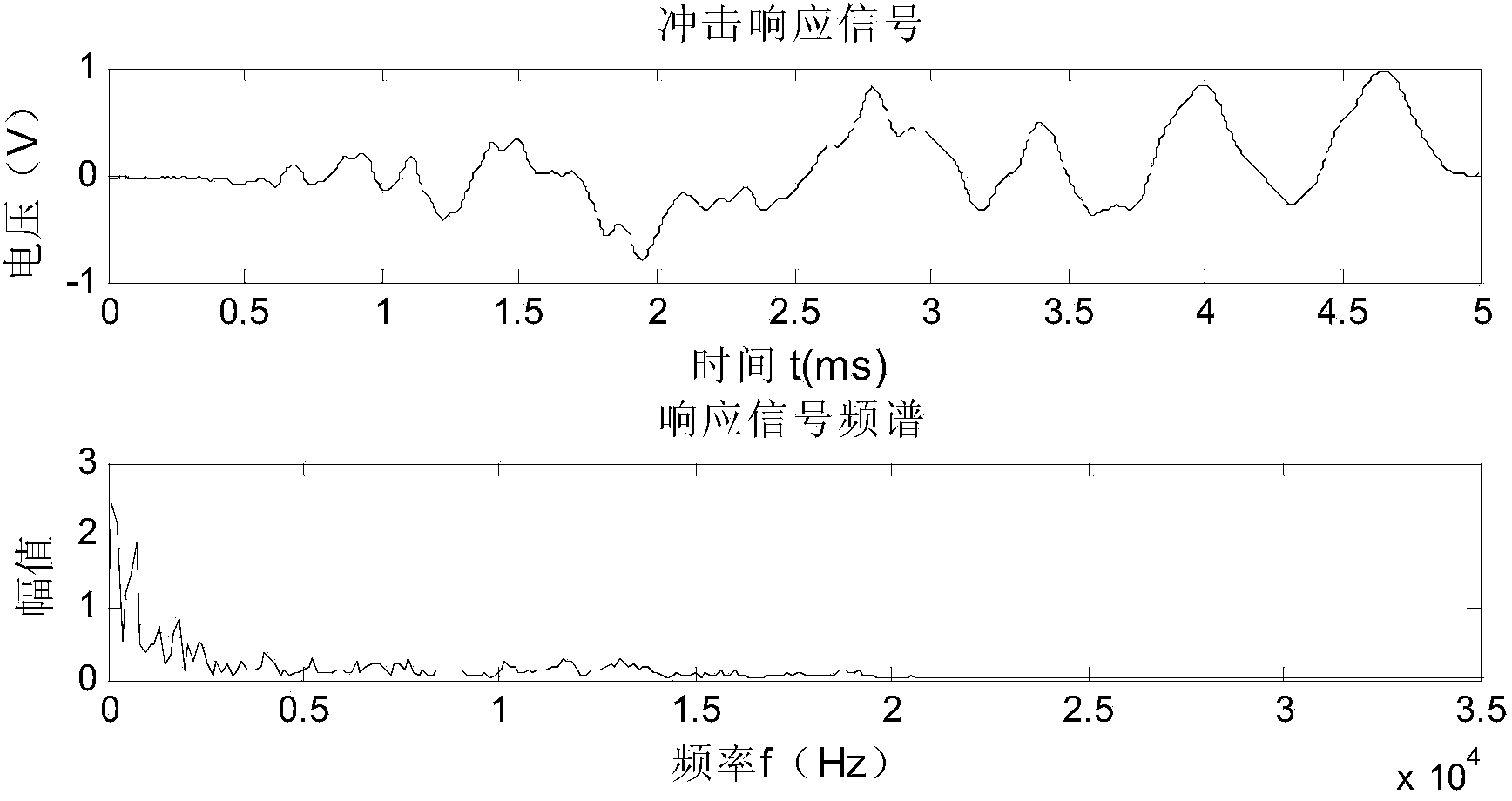

[0087] 1. Impact positioning

[0088] In a broad sense, the impact process belongs to the phenomenon of acoustic emission. According to the time difference positioning method, if the piezoelectric sensors are regularly arranged on the surface of the component (the invention uses four sensors to realize the identification of the impact source), and the sensor signals are properly processed, the time difference of the signals received by the sensors can be measured It can be converted to get the source of acoustic emission, that is, the impact position, such as figure 1 shown. Suppose the coordinates of the shock source I are (x I ,y I), the propagation speed of the Lamb wave induced by the shock is Vg, and the time to reach each sensor is t i , then the location of the shock source can be obtained by solving the following equations:

[0089] (x 1 -x I ) 2 +(x-y I ) 2 -(t 1 V g ) 2 =0

[0090] (x 2 -x I ) 2 +(x-y I ) 2 -[(t 1 +Δt 12 )V g ] 2 = 0 (1)

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com