Automatic leveling laser measurement instrument

A laser measuring instrument and automatic adjustment technology, which is applied in the direction of measuring instruments, measuring devices, instruments, etc., can solve the problems of time-consuming, troublesome equipment leveling, etc., and achieve the effects of increasing sensitivity, avoiding errors, and preventing influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

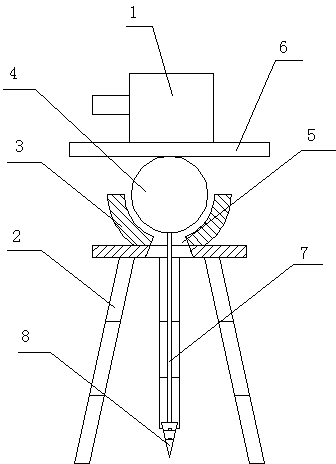

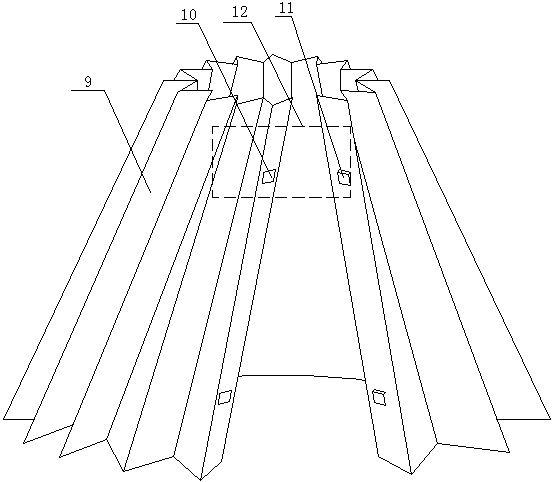

[0022] Such as figure 1 , figure 2 As shown, the automatic leveling laser measuring instrument includes a host 1, a rotatable bracket and a fixed bracket 2. The rotatable bracket includes a bowl-shaped base 3 and a spherical rotating part 4, and the spherical rotating part 4 is located in the bowl-shaped base 3. The bottom of the bowl-shaped base 3 is provided with a through hole 5, and the outer surface of the spherical rotating part 4 and the inner surface of the bowl-shaped base 3 are magnets of the same polarity; a platform 6 is fixed below the host 1, and the platform 6 is fixed on the spherical rotating part by bolts 4, the center of gravity of the main engine 1 and the spherical rotating part 4 is on the same straight line, and the bottom of the spherical rotating part 4 is also connected with a weight 8 through a traction rope 7, and the traction rope 7 passes through the through hole 5 of the bowl-shaped base 3, and the bowl The bottom of the base 3 is fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com