A grouting method for vibration isolation and noise reduction on the outside of subway tunnel segments

A tunnel segment and vibration isolation technology, applied in tunnels, tunnel linings, underground chambers, etc., to achieve the effects of simple sealing, reasonable cost and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the above objects, features and advantages of the present invention more understandable, the embodiments of the present invention will be further described in detail below in conjunction with specific implementation methods.

[0027] Hole layout parameters: in the direction of excavation, grouting is performed every 3-5 shield segments, and the hole layout parameters can be adjusted according to requirements.

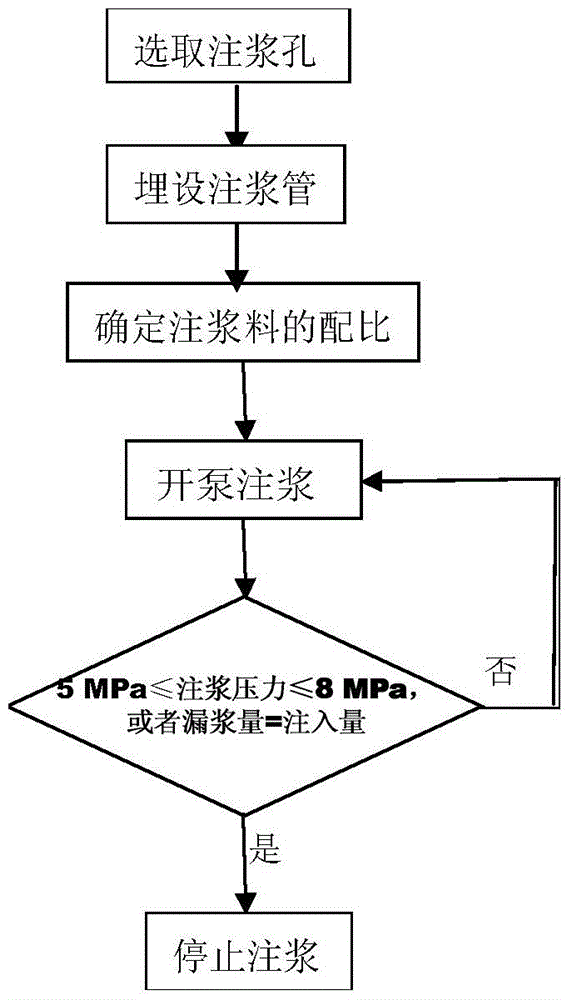

[0028] (1) Bury the grouting pipe at the selected grouting hole;

[0029] (2) Determine the ratio of the vibration isolation and noise reduction material resin to the catalyst, that is, to satisfy the volume ratio of 1:1 and the weight ratio of 1:1.17 at the same time.

[0030] (3) Connect the injection gun and the grouting pump with a high-pressure rubber hose, use a small multifunctional pneumatic grouting pump, and use a double-liquid grouting system to inject the prepared vibration isolation and noise reduction material resin and catalyst int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com